A kind of preparation method of picolinic acid compound

A technology of picolinic acid and compounds, which is applied in the field of preparation of picolinic acid compounds, can solve the problems of high cost, heavy pollution, complicated process, etc., and achieve the effects of low cost, high yield and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

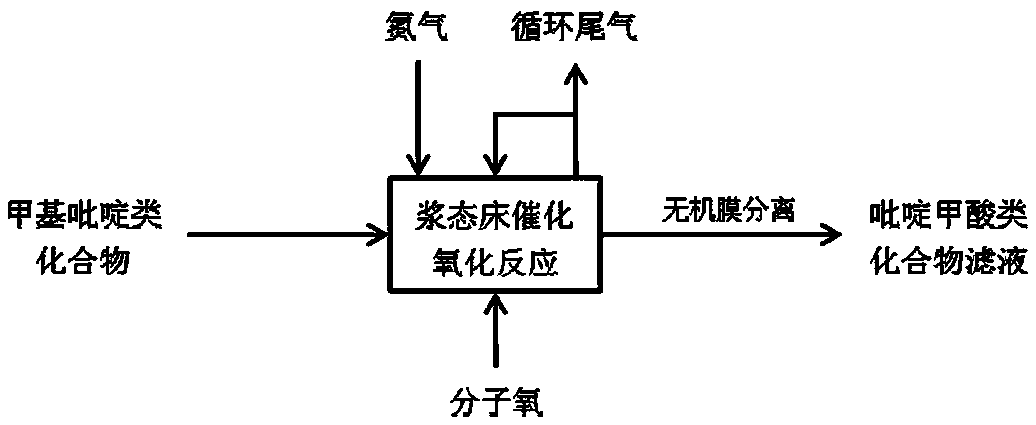

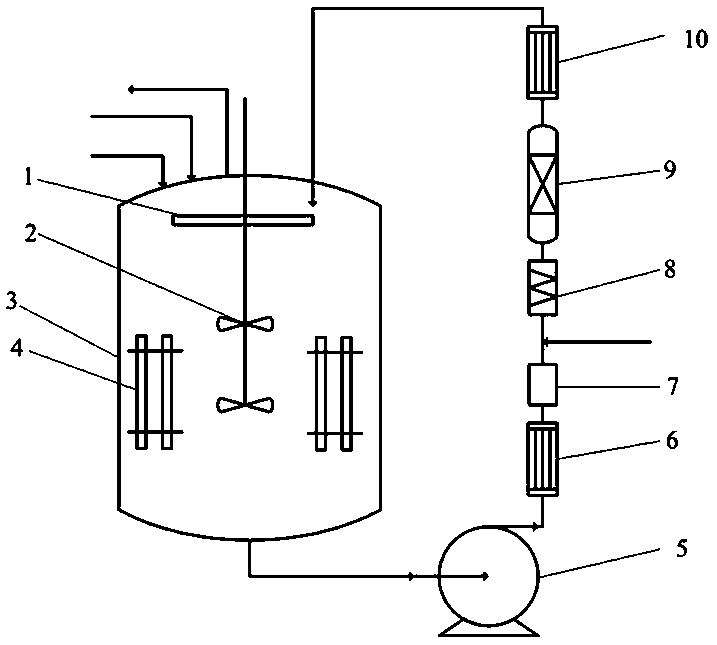

[0030] The preparation method of picolinic acid compounds provided by the invention comprises the following steps:

[0031] Add catalysts and picoline compounds into the slurry bed reactor, and feed protective gas, start the agitator and circulation pump, establish circulation, and then feed gas oxidant into the static mixed gas, in the pre-reactor, a The base pyridine compound is oxidized by the gas oxidant in the presence of the catalyst, and the reaction is completed in the reactor to obtain the reaction solution of the picolinic acid compound. Among them, the picoline compound, protective gas and gas oxidant are all raw materials that are pretreated to the reaction temperature and pressure, and the molar ratio of the picoline compound to the oxidizing component in the gas oxidant is 1:0.05~5, The catalyst can catalyze the oxidation of picoline compounds to generate picolinic acid compounds. The mass concentration of the catalyst is 1%~8%, the reaction temperature in the re...

Embodiment 1

[0037] (1) Raw material pretreatment

[0038] Heat and pressurize 2-picoline to a temperature of 160 °C and a pressure of 1.5 MPa;

[0039] The air is formulated into air with an oxygen mass content of 20%, and then filtered and compressed to a pressure of 1.5MPa, and then preheated to 160 °C;

[0040] Compress nitrogen to a pressure of 1.5 MPa, and then preheat to a temperature of 160 °C.

[0041] (2) Oxidation reaction

[0042] The pretreated 2-picoline, prepared air, and nitrogen in step (1) are continuously sent to the slurry bed oxidation reaction system equipped with a catalyst for catalytic oxidation reaction, and the reaction liquid of 2-pyridinecarboxylic acid is generated . During the reaction process, the reaction temperature was controlled at 160 °C, the pressure was 1.5 MPa, the residence time was 30 min, the molar ratio of 2-picoline to oxygen molecules in the prepared air was 1:0.5, and the mass concentration of the catalyst was 3% (need According to the uni...

Embodiment 2

[0047] (1) Raw material pretreatment

[0048] Heat and pressurize 3-picoline to a temperature of 170 °C and a pressure of 1.6 MPa;

[0049] The air is formulated into air with an oxygen mass content of 30%, and then filtered and compressed to a pressure of 1.6MPa, and then preheated to 170 °C;

[0050] Compress nitrogen or cycle tail gas to a pressure of 1.6 MPa, and then preheat to a temperature of 170 °C. At the beginning of the reaction, nitrogen is used as a protective gas. After the reaction has been carried out for a period of time, the tail gas (mostly nitrogen, containing a very small amount of prepared air) discharged from the slurry bed oxidation reactor is recycled, that is, the circulating tail gas is heated. Autoclave to reaction temperature and pressure.

[0051] (2) Oxidation reaction

[0052] The pretreated 3-picoline, prepared air, and nitrogen (or circulating tail gas) in step (1) are continuously sent to the slurry bed oxidation reaction system equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com