Transition metal phosphide/g-C3N4 composite material as well as preparation method and application thereof

A transition metal and composite material technology, applied in chemical instruments and methods, non-metallic elements, physical/chemical process catalysts, etc., can solve problems such as insufficient catalytic activity, and achieve improved photocatalytic reaction activity, simple operation, and improved catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) g-C 3 N 4 Preparation: 40g of urea was put into a 150ml crucible and calcined in a muffle furnace at 550°C for 4 hours at a heating rate of 10°C / min, and then cooled to room temperature and calcined at 550°C for 2 hours under the same conditions, the reaction was complete After getting yellow g-C 3 N 4 of powder.

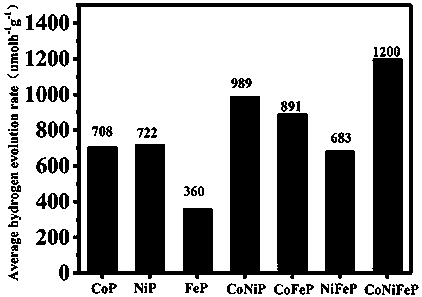

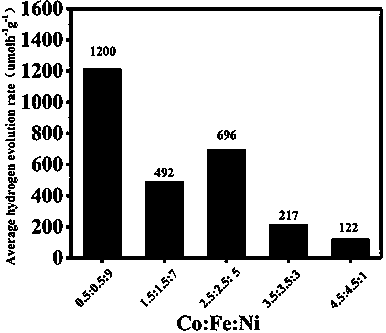

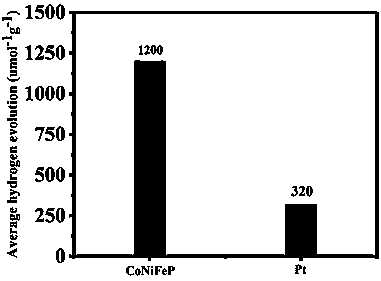

[0045] (2) CoNiFeP / g-C 3 N 4 Preparation of composite materials: 300mg g-C 3 N 4 and 4.5mg of nickel nitrate, 0.25mg of cobalt nitrate and 0.25mg of ferric nitrate were added to the beaker, then 40ml of water was added, ultrasonically dispersed for two hours, and then the suspension was placed in 85°C water heat to dry the water in the reaction system and cooled to room temperature, the obtained sample and 0.2g of sodium hypophosphite were mixed together and calcined at 300°C for 1 hour under a nitrogen atmosphere, then naturally cooled to room temperature, and finally the obtained material was washed and dried naturally to obtain CoNiFeP / g-C 3 N ...

Embodiment 2

[0048] (1) g-C 3 N 4 Preparation: 40g of urea was put into a 150ml crucible and calcined in a muffle furnace at 550°C for 4 hours at a heating rate of 10°C / min, and then cooled to room temperature and calcined at 550°C for 2 hours under the same conditions. After complete, get yellow g-C 3 N 4 of powder.

[0049] (2) CoP / g-C 3 N 4 Preparation of composite materials: 300mg g-C 3 N 4 and 5mg of cobalt nitrate were added to the beaker, then 40ml of water was added, ultrasonically dispersed for two hours, the suspension was placed in 85°C hydrothermal heat to dry the water in the reaction system, cooled to room temperature, the obtained sample and 0.2g hypophosphorous acid Sodium was mixed together and calcined at 300°C for 1 hour under nitrogen atmosphere, then cooled to room temperature naturally, and finally the obtained material was washed and dried naturally to obtain CoP / g-C 3 N 4 Composite material, wherein, the mass percentage of CoP is about 0.5%, g-C 3 N 4 The...

Embodiment 3

[0051] (1) g-C 3 N 4 Preparation: 40g of urea was put into a 150ml crucible and calcined in a muffle furnace at 550°C for 4 hours at a heating rate of 10°C / min, and then cooled to room temperature and calcined at 550°C for 2 hours under the same conditions. After complete, get yellow g-C 3 N 4 of powder.

[0052] (2) NiP / g-C 3 N 4 Preparation of composite materials: 300mg g-C 3 N 4 and 5mg of nickel nitrate were added to the beaker, then 40ml of water was added, ultrasonically dispersed for two hours, the suspension was placed in 85°C hydrothermal heat to dry the water in the reaction system, cooled to room temperature, the obtained sample and 0.2g hypophosphorous acid Sodium was mixed together and calcined at 300°C for 1 hour under a nitrogen atmosphere, then naturally cooled to room temperature, and finally the resulting material was washed and dried naturally to obtain NiP / g-C 3 N 4 Composite material, wherein, the mass percentage of NiP is about 0.5%, g-C 3 N 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com