Method for preparing boric acid from boron ore

A technology of boric acid and boron ore, which is applied in the direction of chemical instruments and methods, boron compounds, boron oxide compounds, etc., can solve the problems of poor operability, inability to recycle, and large dosage, so as to improve gloss and quality, reduce Extraction cost, the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

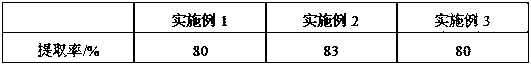

Embodiment 1

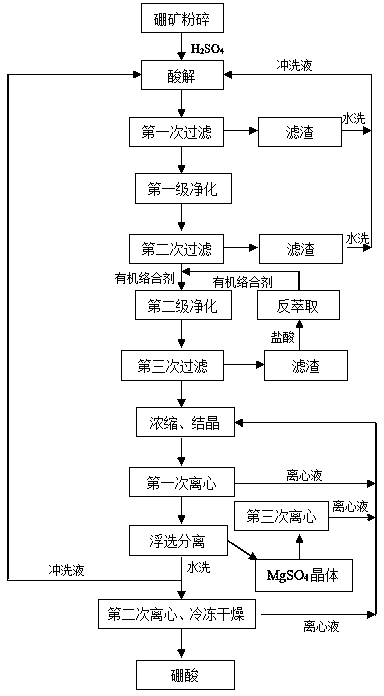

[0025] A method for preparing boric acid from boron ore, comprising the following:

[0026] (1) Ore crushing: Use an ore crusher to crush the ore to a crushing degree of 300 mesh, add 70% sulfuric acid to the mineral powder according to the ratio of material to liquid of 1:3, add sulfuric acid while stirring, and raise the temperature. Acid hydrolysis at 90°C for 1.5 hours, the pH of acid hydrolysis is 4; the first filtration is performed after acid hydrolysis, the filtrate after the first filtration enters the next process, and the rinse solution formed after the filter residue is washed with water is returned to the acid hydrolysis solution further acid hydrolysis;

[0027] (2) First-stage purification: Add 2 times the volume of hydrogen peroxide and 30% sodium sulfide to the filtrate of step (1), and react at a temperature of 90°C for 12 minutes to make the manganese, arsenic and Part of the aluminum ions and iron ions are precipitated; after the first level of purificatio...

Embodiment 2

[0034] A method for preparing boric acid from boron ore, comprising the following:

[0035] (1) Ore crushing: Use an ore crusher to crush the ore to a crushing degree of 200 mesh, add 80% sulfuric acid to the mineral powder according to the ratio of material to liquid of 1:2, add sulfuric acid while stirring, and raise the temperature. Acid hydrolysis at 100°C for 1 hour, the pH of the acid hydrolysis is 5; after the acid hydrolysis, the first filtration is carried out, and the filtrate after the first filtration enters the next process, and the washing liquid formed after the filter residue is washed with water is returned to the acid hydrolysis solution for further Acid hydrolysis;

[0036] (2) First-stage purification: Add 3 times the volume of hydrogen peroxide and 40% sodium sulfide to the filtrate of step (1), and react at a temperature of 100°C for 10 minutes to make the manganese, arsenic and Part of the aluminum ions and iron ions are precipitated; after the first le...

Embodiment 3

[0043] A method for preparing boric acid from boron ore, comprising the following:

[0044] (1) Ore crushing: use an ore crusher to crush the ore to a degree of 250 mesh, add 75% sulfuric acid to the ore powder according to the ratio of material to liquid of 1:3, add sulfuric acid while stirring, increase the temperature, and the temperature is Acidolysis at 95°C for 1 hour, the pH of acidolysis is 4; after acidolysis, the first filtration is performed, the filtrate after the first filtration enters the next process, and the rinsing solution formed after the filter residue is rinsed with water is returned to the acidolysis solution for further acidolysis;

[0045] (2) First-stage purification: add 2 times the volume of hydrogen peroxide and sodium sulfide with a concentration of 35% to the filtrate in step (1), and react at a temperature of 95 ° C for 10 minutes to make manganese, arsenic and arsenic in the filtrate. Part of the aluminum ions and iron ions are precipitated; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com