Low-phosphorous scale and corrosion inhibitor and preparation method thereof

A technology of scale and corrosion inhibitor and mass percentage, applied in the field of water treatment agent and its manufacturing, can solve the problems of eutrophication of water body, not meeting the needs of green environmental protection development, etc., and achieves small environmental impact, excellent dispersion effect, and good dispersion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0065] A low-phosphorus scale and corrosion inhibitor, in terms of mass percentage, the content of each component is shown in the table below,

[0066] Each component content table in table 1. embodiment 1-6

[0067]

[0068] Wherein, hydrochloric acid is the industrial hydrochloric acid that mass percent concentration is 31%.

[0069] Zinc chloride can also be replaced by zinc sulfate and zinc nitrate.

[0070] Carboxylic acid-sulfonic acid-acrylate terpolymer is formed by copolymerization of carboxylic acid monomer, sulfonic acid monomer and acrylate monomer, and the molecular weight is ≤500Da; wherein, the carboxylic acid monomer can be selected from crotonic acid, β- Any one of phenylacrylic acid, maleic acid and fumaric acid; the sulfonic acid monomer can be selected from any one of 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid; The body can be selected from any one of 2-methyl methacrylate, 2-ethyl methacrylate, methyl acrylate and ethyl acrylate. ...

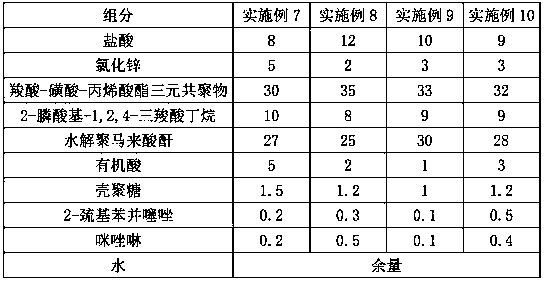

Embodiment 7-10

[0072] A low-phosphorus scale and corrosion inhibitor, in terms of mass percentage, the content of each component is shown in the table below,

[0073] Each component content table in table 2. embodiment 7-10

[0074]

[0075] Wherein, hydrochloric acid is the industrial hydrochloric acid that mass percent concentration is 31%.

[0076] Zinc chloride can also be replaced by zinc sulfate and zinc nitrate.

[0077] Carboxylic acid-sulfonic acid-acrylate terpolymer is formed by copolymerization of carboxylic acid monomer, sulfonic acid monomer and acrylate monomer, and the molecular weight is ≤500Da; wherein, the carboxylic acid monomer can be selected from crotonic acid, β- Any one of phenylacrylic acid, maleic acid and fumaric acid; the sulfonic acid monomer can be selected from any one of 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid; The body can be selected from any one of 2-methyl methacrylate, 2-ethyl methacrylate, methyl acrylate and ethyl acrylate. ...

Embodiment 11-14

[0080] A low-phosphorus scale and corrosion inhibitor, in terms of mass percentage, the content of each component is shown in the table below,

[0081] Table 3. Each component content table in embodiment 11-14

[0082]

[0083] Wherein, hydrochloric acid is the industrial hydrochloric acid that mass percent concentration is 31%.

[0084] Zinc chloride can also be replaced by zinc sulfate and zinc nitrate.

[0085] Carboxylic acid-sulfonic acid-acrylate terpolymer is formed by copolymerization of carboxylic acid monomer, sulfonic acid monomer and acrylate monomer, and the molecular weight is ≤500Da; wherein, the carboxylic acid monomer can be selected from crotonic acid, β- Any one of phenylacrylic acid, maleic acid and fumaric acid; the sulfonic acid monomer can be selected from any one of 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid; The body can be selected from any one of 2-methyl methacrylate, 2-ethyl methacrylate, methyl acrylate and ethyl acrylate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com