Antistatic fabric preparation method

A technology of antistatic fabric and mass ratio, which is applied in the manufacture of conductive/antistatic filaments, rayon, textiles and paper, etc. It can solve the problems of poor air permeability, insufficient comfort of antistatic fabrics, poor mechanical properties and durability and other problems, to achieve the effect of good washability, good elasticity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

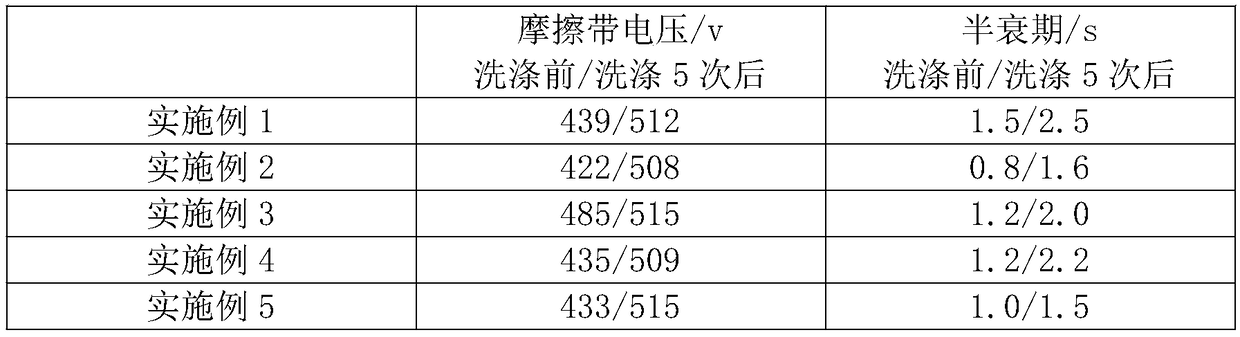

Examples

Embodiment 1

[0031] A preparation method of antistatic fabric, comprising the following steps:

[0032] (1) dissolving chitosan in water to make mass concentration is 5% chitosan solution;

[0033] (2) Stir methyl methacrylate and water, then add an emulsifier for emulsification treatment, add the chitosan solution prepared above dropwise, stir and mix for 10 minutes, then slowly raise the temperature to 60°C, and stir for 1 hour to obtain a shell A polyacrylate emulsion modified by polysaccharide crosslinking; wherein the mass ratio of methyl methacrylate to chitosan is 3.3:1;

[0034] (3) adding the above-mentioned prepared chitosan cross-linked modified polyacrylate emulsion into a container for electrospinning, and inducing bundles of fibers produced by electrospinning, and making yarn after twisting;

[0035] (4) polyamide resin, carbon nanotubes, calcium carbonate, and sodium chloride are added to a kneader and mixed for 5-10 minutes, then extruded and granulated by a twin-screw ext...

Embodiment 2

[0041] A preparation method of antistatic fabric, comprising the following steps:

[0042] (1) dissolving chitosan in water to make a mass concentration of 15% chitosan solution;

[0043] (2) Stir methyl methacrylate and water, then add an emulsifier for emulsification treatment, add the chitosan solution prepared above dropwise, stir and mix for 30 minutes, then slowly raise the temperature to 80°C, and stir for 2 hours to obtain a shell A polyacrylate emulsion modified by polysaccharide crosslinking; wherein, the mass ratio of methyl methacrylate and chitosan is 7.5:1;

[0044] (3) adding the above-mentioned prepared chitosan cross-linked modified polyacrylate emulsion into a container for electrospinning, and inducing bundles of fibers produced by electrospinning, and making yarn after twisting;

[0045] (4) polyamide resin, carbon nanotubes, calcium carbonate, and sodium chloride are added to a kneader and mixed for 5-10 minutes, then extruded and granulated by a twin-scr...

Embodiment 3

[0051] A preparation method of antistatic fabric, comprising the following steps:

[0052] (1) dissolving chitosan in water to obtain a mass concentration of 7% chitosan solution;

[0053] (2) Stir methyl methacrylate and water, then add an emulsifier for emulsification treatment, add the chitosan solution prepared above dropwise, stir and mix for 15 minutes, then slowly raise the temperature to 65°C, and stir for 1.3 hours to obtain Chitosan cross-linked modified polyacrylate emulsion; wherein, the mass ratio of methyl methacrylate and chitosan is 4.5:1;

[0054] (3) adding the above-mentioned prepared chitosan cross-linked modified polyacrylate emulsion into a container for electrospinning, and inducing bundles of fibers produced by electrospinning, and making yarn after twisting;

[0055] (4) polyamide resin, carbon nanotubes, calcium carbonate, and sodium chloride are added to a kneader and mixed for 5-10 minutes, then extruded and granulated by a twin-screw extruder, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com