Muck foundation material and method for constructing roadbed by using foundation material

A silt foundation and silt technology, which is applied in the field of road engineering construction, can solve the problems of inability to remove the special odor of silt, silt cannot be used as a foundation material, and the road matrix has high rigidity, etc. The effect of soil strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

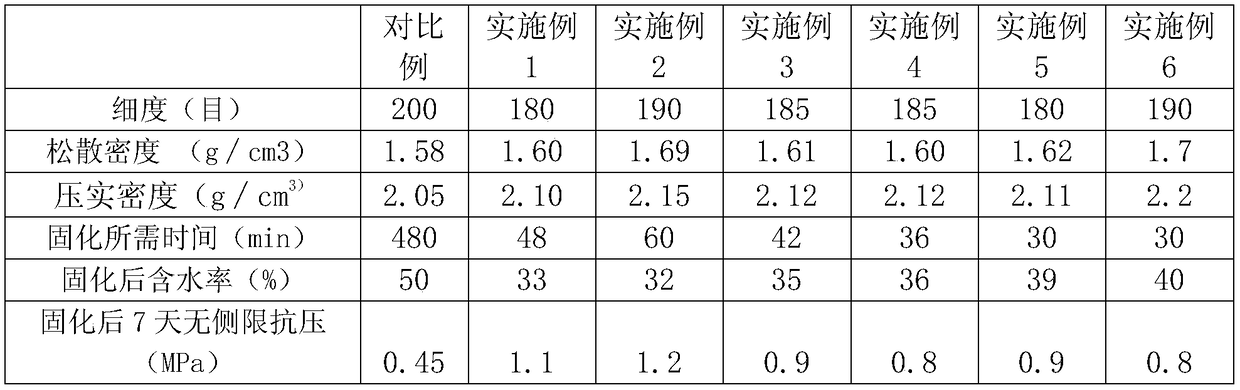

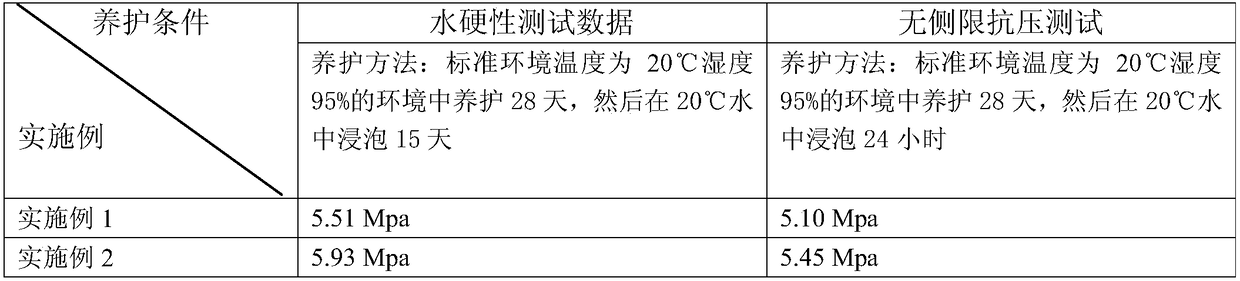

Embodiment 1

[0037] Embodiment 1 is a method for constructing roadbeds with silt foundation materials, characterized in that the specific steps are as follows:

[0038] (1) according to the formula preparation sludge solidifying agent of following mass percent: 25% slag, 21% modified diatomite, 22% attapulgite, 10% microsilica, 4% powder activated carbon, 7.5% potassium peroxide, 2% potassium permanganate, 1.5% iron powder, 3% polyrotaxane, 3% sodium polyacrylate, 0.5% calcium hydroxide, 0.3% naphthalene superplasticizer, 0.2% polyacrylamide, mix and stir the above raw materials Uniformly obtain sludge curing agent;

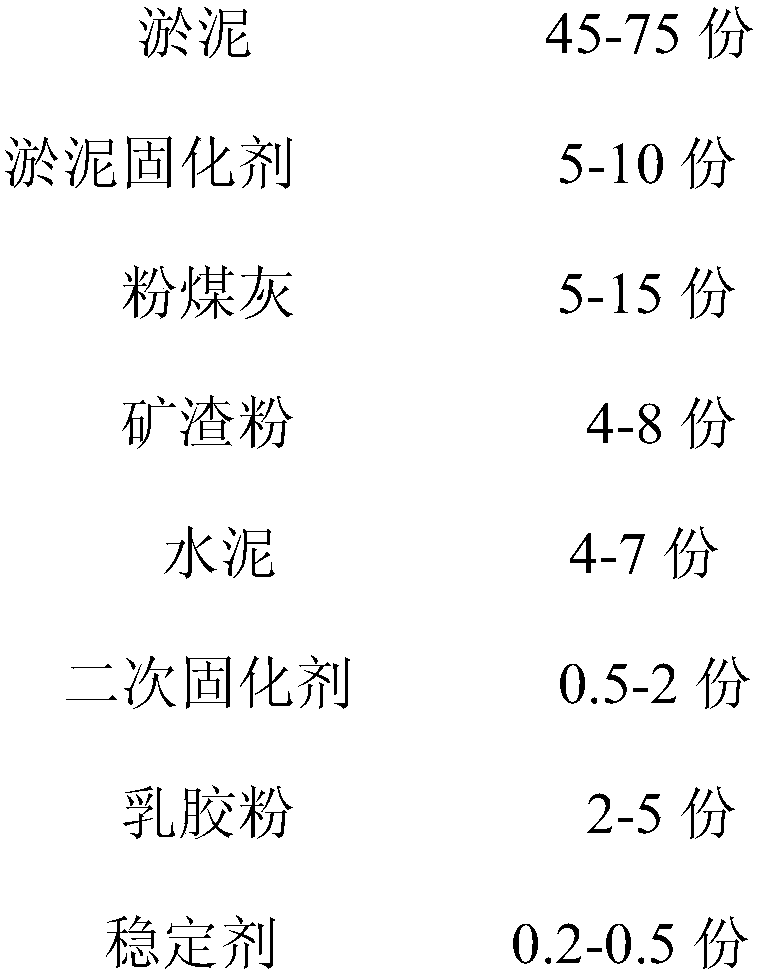

[0039] (2) prepare the raw material of foundation material according to following formula: 74 parts of silt, 10 parts of silt curing agent in step (1), 5 parts of fly ash, 4 parts of slag powder, 4 parts of cement, 0.8 part of curing agent, latex powder 2 parts, 0.2 parts of stabilizer;

[0040] (3) After getting 74 parts of silt and 10 parts of silt solidifying agent in st...

Embodiment 2

[0043] Embodiment 2 A method of constructing a roadbed with silt foundation materials, is characterized in that the specific steps are as follows:

[0044] (1) according to the formula preparation sludge solidifying agent of following mass percent: 20% slag, 23% modified diatomite, 21% attapulgite, 14% microsilica, 6% powder activated carbon, 6% magnesium peroxide, 1% potassium permanganate, 1% iron powder, 2% cationic chelate, 3% polyrotaxane, 2.4% sodium polyacrylate, 0.3% sodium silicate, 0.2% naphthalene superplasticizer, 0.1% polypropylene For amides, the above-mentioned raw materials are fully mixed and stirred in a mixer; the cationic chelate is formed by chelating ethylenediaminetetraacetic acid (EDTA) and calcium ions.

[0045] (2) Prepare the raw materials of the foundation material according to the following formula: 60 parts of silt, 8 parts of silt curing agent in step (1), 9.5 parts of fly ash, 10 parts of slag powder, 8 parts of cement, 1.2 parts of curing agent...

Embodiment 3

[0049] Embodiment 3 provides a method for constructing roadbeds with silt foundation materials, which is characterized in that the specific steps are as follows:

[0050] (1) According to the formula preparation sludge solidifying agent of following mass percentage: at first according to the material preparation raw material of following mass percentage: 15% slag, 24% modified diatomite, 20% attapulgite, 15% microsilica, 8 % powdered activated carbon, 5% calcium peroxide, 2% potassium permanganate, 2.2% iron powder, 4% cationic chelate, 1.5% polyrotaxane, 2% sodium polyacrylate, 0.6% calcium hydroxide, 0.4% naphthalene It is a high-efficiency water reducer and 0.3% polyaluminum chloride. The above-mentioned raw materials are fully mixed and stirred in a mixer; the cationic chelate is formed by chelating dihydroxyethylglycine (DEG) and magnesium ions.

[0051] (2) prepare the raw material of foundation material according to following formula: 65 parts of silt, 8 parts of silt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com