Biodegradable microsphere coating fertilizer

A biodegradable and coated fertilizer technology, applied in the direction of layered/coated fertilizers, nitrogen fertilizers, phosphate fertilizers, etc., can solve the problems of large differences in fertilizer release rates, difficult degradation of coating materials, degradation rates, and degradation capabilities that have not reached the expected level, etc. problems, to avoid environmental pollution and soil agglomeration, suitable for large-scale production, simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A biodegradable microsphere-coated fertilizer, which is prepared according to the following steps:

[0025] Add polybutylene succinate to chloroform, the ratio of polybutylene succinate and chloroform is 1g: 10ml, stir until dissolved, then add one-tenth of polybutylene succinate Starch ether in parts by weight, stirred at 200 rpm for 10 minutes, then added ethanol with the same volume as chloroform, allowed to stand for 30 minutes, collected the precipitate, put it into a freeze dryer, and dried for 12 hours to obtain a microsphere carrier;

[0026] Add urea, potassium nitrate, superphosphate and water into the stirring tank according to the mass ratio of 3:3:1:10, stir at 300rpm for 30min, then enter the reaction tank, and heat to 70°C at a heating rate of 10°C / min. Insulate and react for 10 minutes, then cool to room temperature, and then stand still for 6 hours to obtain liquid fertilizer;

[0027] Paenibacillus polymyxa, Trichoderma harzianum and Bacillus megateri...

Embodiment 2

[0032] A biodegradable microsphere-coated fertilizer, which is prepared according to the following steps:

[0033] Add polybutylene succinate to chloroform, the ratio of polybutylene succinate and chloroform is 1g: 10ml, stir until dissolved, then add one-tenth of polybutylene succinate Starch ether in parts by weight, stirred at 200 rpm for 10 minutes, then added ethanol with the same volume as chloroform, allowed to stand for 30 minutes, collected the precipitate, put it into a freeze dryer, and dried for 12 hours to obtain a microsphere carrier;

[0034] Add urea, potassium nitrate, superphosphate and water into the stirring tank at a mass ratio of 5:5:2:20, stir at 300rpm for 30min, then enter the reaction tank, and heat to 70°C at a heating rate of 10°C / min. Insulate and react for 10 minutes, then cool to room temperature, and then stand still for 6 hours to obtain liquid fertilizer;

[0035] Paenibacillus polymyxa, Trichoderma harzianum and Bacillus megaterium were cult...

Embodiment 3

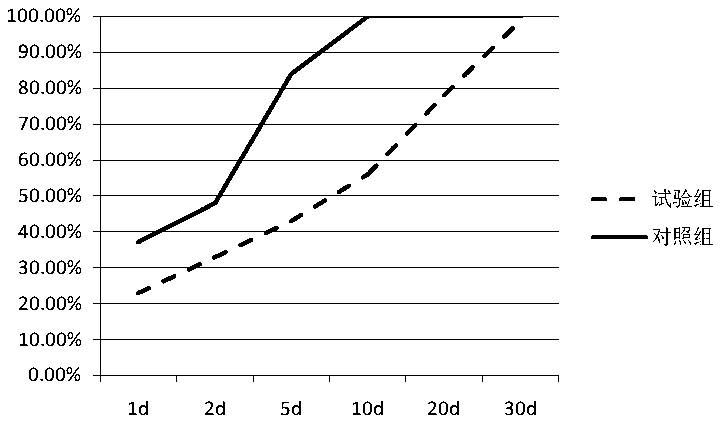

[0039] 1. Urea release time test:

[0040] The test group is Example 1; the control group: chitosan microsphere carrier, and the rest are the same as Example 1. as attached figure 1 As shown, the control group released all urea within 10 days, while the urea release rate of the test group was stable and orderly, which was basically synchronized with the crop nutrient absorption, avoiding the defects that most of the slow-release fertilizers were released too quickly and lost a lot in the early stage. The effect is obviously better than the chitosan microsphere carrier commonly used in the market.

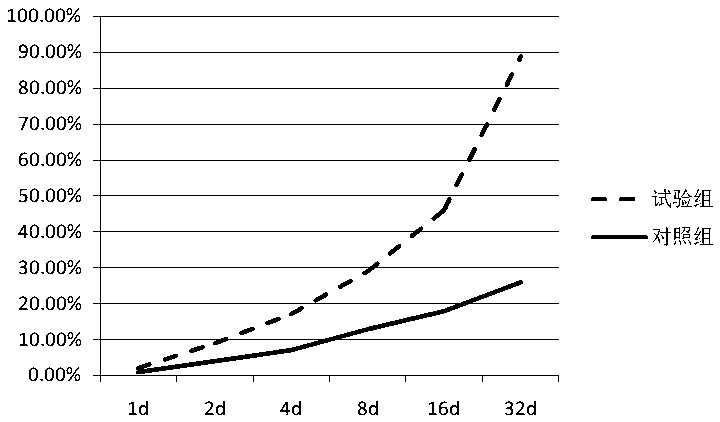

[0041] 2. Microsphere carrier degradation time test:

[0042] The test group is the embodiment 1; the control group 1: no compound bacteria solution is added, and the rest are the same as the embodiment 1. as attached figure 2 As shown, the difference in the degradation rate between the test group and the control group in the early stage is not large, which may be due to the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com