Primary explosive crystallization system based on segmented flow

A technology of crystallization system and priming charge, which is applied in the direction of explosives, explosives processing equipment, offensive equipment, etc., can solve the problem that the synthesis method cannot detect the combination of equipment, cannot obtain the crystallization kinetic information of the priming charge online, and there is no research on the mechanism of the crystallization process of the priming charge. Substantial progress and other issues have been achieved to achieve the effects of shortening the residence time, lowering the cost and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

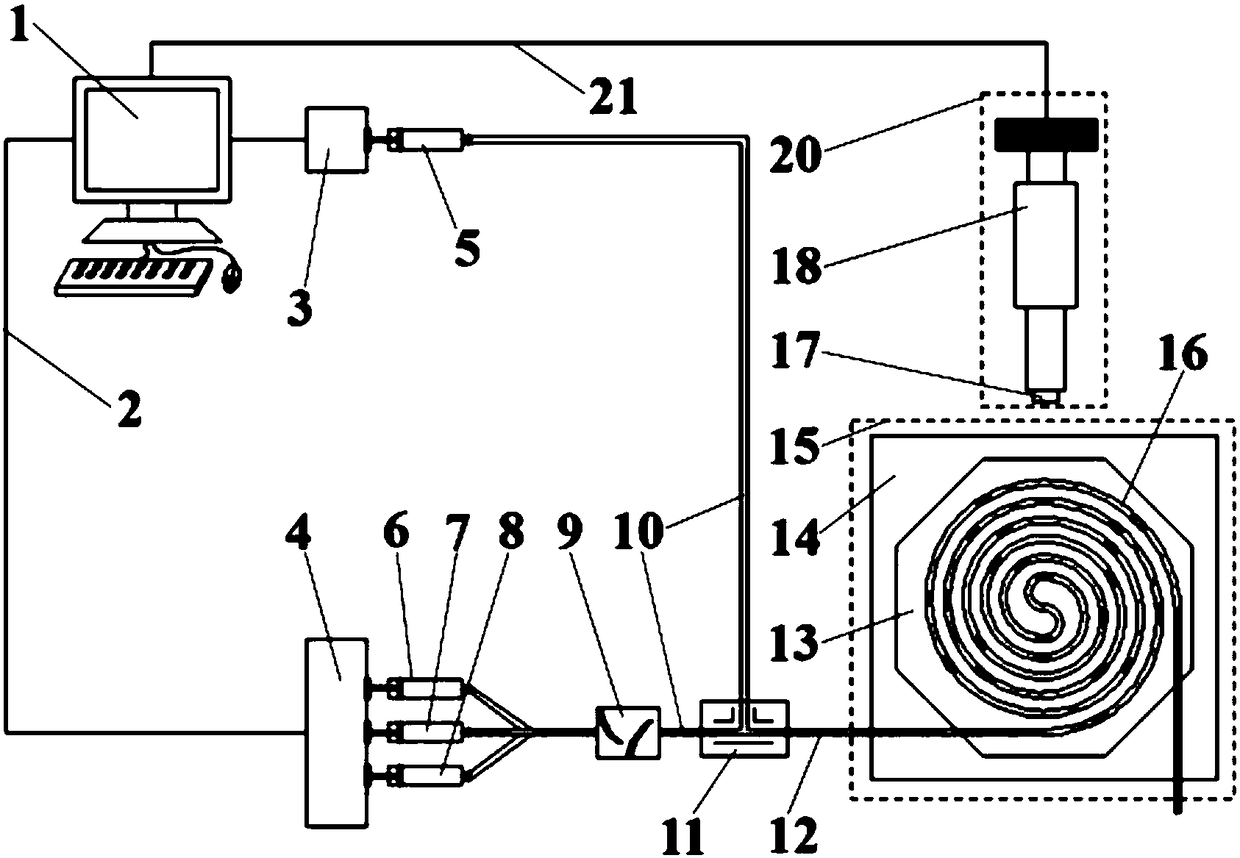

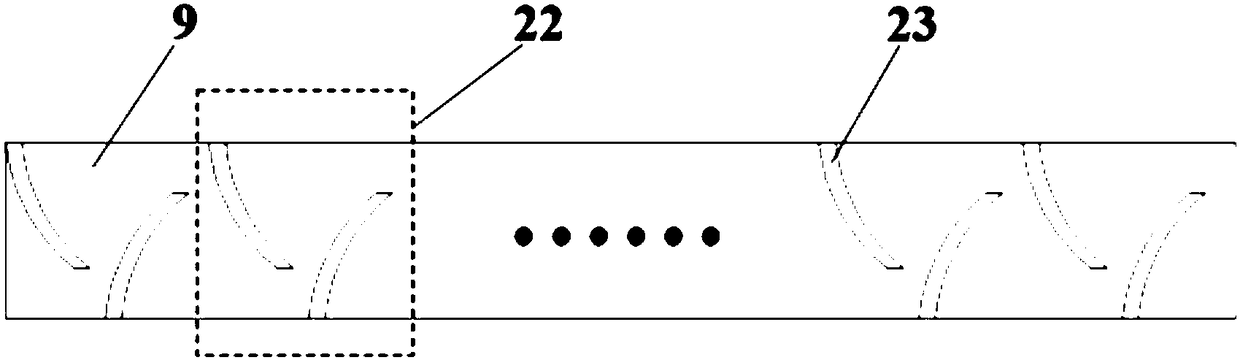

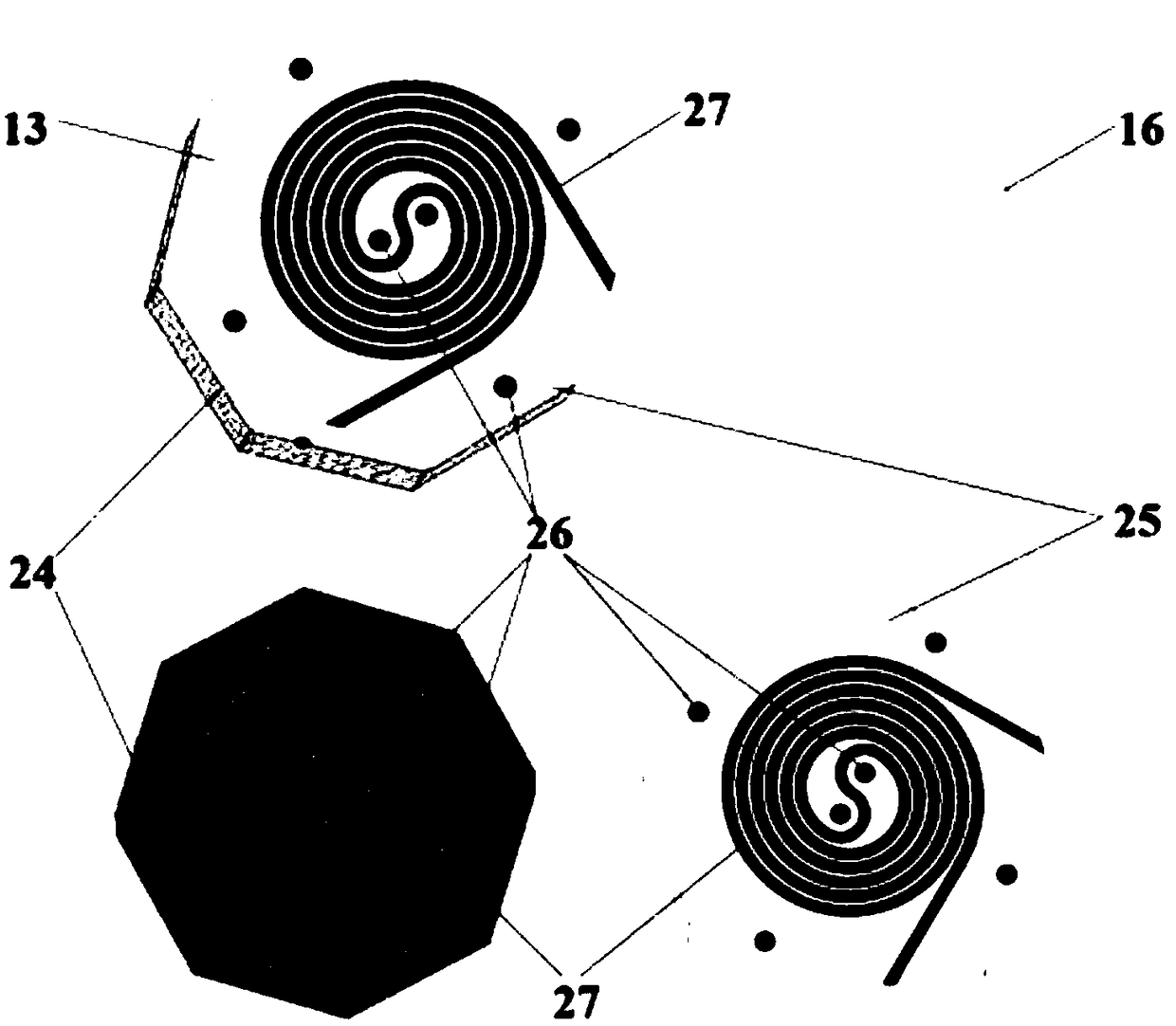

[0050] Example 1: Preparation and crystallization observation of crystalline lead trinitroresorcinol

[0051] Prepare 10 mL of magnesium stephenate solution of 0.1 mol / L, adjust the pH value to 4.0, 10 mL of 0.15 mol / L lead nitrate solution, adjust the pH value to 4.0, and place the two reaction solutions in syringe 6 and syringe 7, by The computer set the injection rate to 0.15mL / min; take 20mL of n-tetradecane and place it in the 20mL syringe 5, and set the injection rate to 0.3mL / min by the computer. The heating temperature of the water bath was 65°C. Turn on the continuous phase carrier liquid injection pump, and turn on the reaction liquid drive pump after the fluid flow is stable. The micro-mixer adopts a micro-mixing unit, and the reaction liquid is mixed quickly and evenly. After the fluid passes through the T-shaped connector, a droplet with a uniform shape is formed, and a chemical reaction occurs in the droplet, and the droplet enters the crystallization device to...

Embodiment 2

[0052] Embodiment 2: the preparation of crystalline barium trinitroresorcinate

[0053] Prepare 10 mL of magnesium stephenate solution of 0.15 mol / L, adjust the pH value to 4.5, 10 mL of barium nitrate solution of 0.15 mol / L, adjust the pH value to 5.0, and place two kinds of reaction solutions in syringe 6 and syringe 7, by The computer set the injection rate to 0.1mL / min; take 20mL of n-tetradecane and place it in the 20mL syringe 5, and set the injection rate to 0.2mL / min by the computer. The heating temperature of the water bath is 70°C. Turn on the continuous phase carrier liquid injection pump, and turn on the reaction liquid drive pump after the fluid flow is stable. The micro-mixer adopts a micro-mixing unit, and the reaction liquid is mixed quickly and evenly. After the fluid passes through the T-shaped connector, a droplet with a uniform shape is formed, and a chemical reaction occurs in the droplet, and the droplet enters the crystallization device to produce bari...

Embodiment 3

[0054] Embodiment 3: the preparation of carboxymethyl cellulose lead azide

[0055] The preparation mass fraction is 5% sodium azide solution 10mL, adjusts the pH value to 9.0, the mass fraction 15% lead acetate solution 10mL, adjusts the pH value to 5.5, and two kinds of reaction solutions are placed in syringe 6 and syringe 7, Prepare a sodium carboxymethylcellulose solution with a mass fraction of 0.1% and place it in the syringe 8, set the injection rate to 0.1mL / min by the computer; take 20mL of n-octadecane and place it in the 20mL syringe 5, set the injection rate by the computer The rate was 0.2 mL / min. The heating temperature of the water bath was 35°C. Turn on the continuous phase carrier liquid injection pump, and turn on the reaction liquid drive pump after the fluid flow is stable. The micro-mixer adopts a micro-mixing unit, and the reaction liquid is mixed quickly and evenly. After the fluid passes through the T-shaped connector, a droplet with a uniform shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com