Sealing material of asphalt pavement water permeation coefficient

A water permeability coefficient and sealing material technology, applied in suspension and porous material analysis, permeability/surface area analysis, measuring devices, etc., can solve problems such as insufficient viscosity of putty or plasticine, difficult test work, and poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

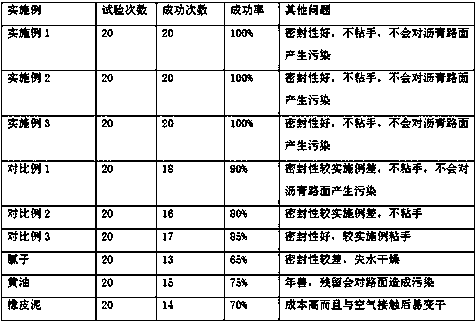

Examples

Embodiment 1

[0017] A sealing material for the water permeability coefficient of asphalt pavement, comprising component A and component B, wherein component A is composed of the following raw materials in weight ratio: 22 parts of modified emulsified asphalt, 0.8 part of VAE, 20 parts of bentonite, 2.5 parts of borax 6 parts, 6 parts of sodium lignosulfonate, 2 parts of silane coupling agent; Component B is made of the raw materials of following weight ratio: 20 parts of fly ash, 1 part of VAE, 20 parts of bentonite, 1 part of methyl cellulose ether.

[0018] The preparation method of modified emulsified asphalt: heat the asphalt to 180-190°C, set aside, dissolve sodium dodecylbenzenesulfonate, isotridecanyl polyoxyethylene ether and bentonite in water, the quality of the three components and water Ratio 1:1.2:1:100, after being fully dissolved, heat to 65°C, add calcium chloride and sodium chloride, mix with asphalt, stir evenly, then add glycerin, grind evenly, cool down to obtain modific...

Embodiment 2

[0023] A sealing material for the water permeability coefficient of asphalt pavement, comprising component A and component B, wherein component A is composed of the following raw materials in weight ratio: 18 parts of modified emulsified asphalt, 0.5 part of VAE, 15 parts of bentonite, 2 parts of borax Parts, 5 parts of sodium lignosulfonate, 1 part of silane coupling agent; Component B consists of the following raw materials in weight ratio: 15 parts of fly ash, 0.5 part of VAE, 18 parts of bentonite, 0.2 part of methyl cellulose ether.

[0024] The preparation method of modified emulsified asphalt: heat the asphalt to 180°C, set aside, dissolve sodium dodecylbenzenesulfonate, isotridecanyl polyoxyethylene ether and bentonite in water, and the mass ratio of the three components to water is 1 :1:0.5:100, after being fully dissolved, heat to 65°C, add calcium chloride and sodium chloride, mix with asphalt, stir evenly, then add glycerin, grind evenly, cool down to obtain modifie...

Embodiment 3

[0027] A sealing material for asphalt pavement water seepage coefficient, comprising component A and component B, wherein component A is composed of the following raw materials in weight ratio: 25 parts of modified emulsified asphalt, 2 parts of VAE, 22 parts of bentonite, 5 parts of borax, 8 parts of sodium lignosulfonate, 5 parts of silane coupling agent; Component B consists of the following raw materials in the weight ratio: 22 parts of fly ash, 2 parts of VAE, 25 parts of bentonite, and 1.5 parts of methyl cellulose ether.

[0028] The preparation method of modified emulsified asphalt: heat the asphalt to 190°C, set aside, dissolve sodium dodecylbenzenesulfonate, isotridecanyl polyoxyethylene ether and bentonite in water, and the mass ratio of the three components to water is 1 :2:3:100, after being fully dissolved, heat to 65°C, add calcium chloride and sodium chloride, mix with asphalt, stir evenly, then add glycerol, grind evenly, cool down to obtain modified emulsified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com