Enteric algal polysaccharide vacant capsule and preparation method thereof

A technology of seaweed polysaccharides and hollow capsules, applied in the direction of capsule delivery, inorganic non-active ingredients, etc., to achieve high tolerance, reduce irritation, and control the effect of drug release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

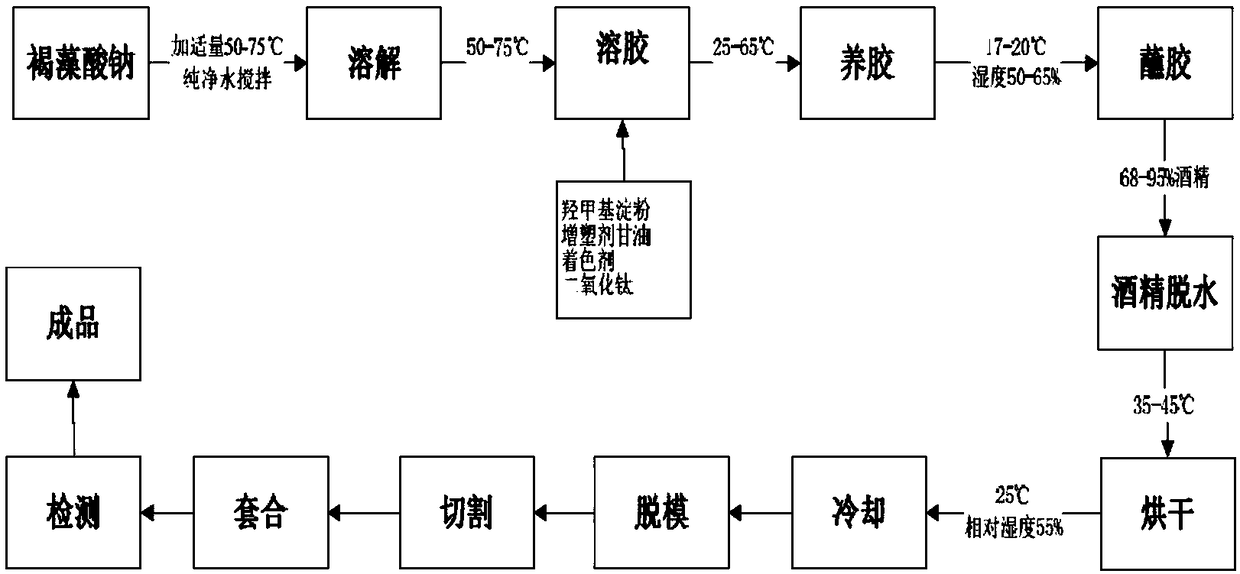

Method used

Image

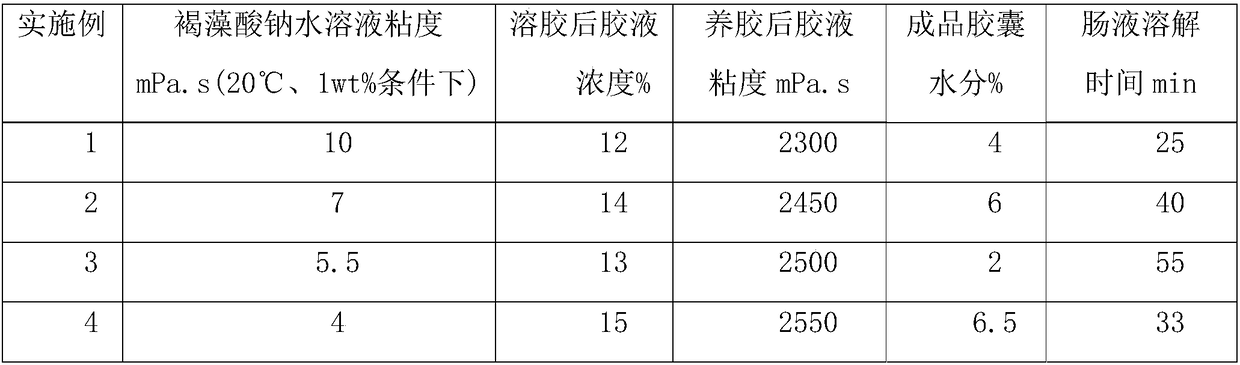

Examples

Embodiment 1

[0053] A preparation method of enteric-coated seaweed polysaccharide hollow capsules, the preparation steps are as follows:

[0054] (1) dissolve

[0055] First add 85g of sodium alginate to an appropriate amount of 70°C pure water, soak, expand and stir in the sol tank to dissolve the sodium alginate;

[0056] (2) Sol

[0057] Stir the above ingredients at 70°C for 3 hours. After they are completely dissolved, add 15 g of hydroxymethyl starch, 2 g of glycerin, 0.03 g of food coloring and 4 g of titanium dioxide in sequence, and dissolve completely to prepare a glue solution with a concentration of 12%.

[0058] (3) Raw glue

[0059] After stirring evenly, transfer to an automatic temperature-controlled stainless steel bucket for glue cultivation, keep warm at 50°C, and after standing for 6 hours, remove the foam on the surface. After the glue cultivation, the viscosity of the glue reaches 2300mPa.s;

[0060] (4) dipped in glue

[0061] After the glue cultivation is comple...

Embodiment 2

[0073] A preparation method of enteric-coated seaweed polysaccharide hollow capsules, the preparation steps are as follows:

[0074] (1) dissolve

[0075] First add 90g of sodium alginate to an appropriate amount of 60°C pure water, soak, expand and stir in the sol tank to dissolve the sodium alginate;

[0076] (2) Sol

[0077] Stir the above ingredients for 4 hours at a temperature of 65°C. After they are completely dissolved, add 10 g of hydroxymethyl starch, 3 g of glycerin, 0.01 g of food coloring and 1 g of titanium dioxide in order to completely dissolve and prepare a glue solution with a concentration of 14%.

[0078] (3) Raw glue

[0079] After stirring evenly, transfer it to an automatic temperature-controlled stainless steel bucket for glue cultivation, keep it warm at 60°C, and after standing for 1.5 hours, remove the foam on the surface. After the glue cultivation, the viscosity of the glue reaches 2450mPa.s;

[0080] (4) dipped in glue

[0081] After the glue ...

Embodiment 3

[0093] A preparation method of enteric-coated seaweed polysaccharide hollow capsules, the preparation steps are as follows:

[0094] (1) dissolve

[0095] First add 80g of sodium alginate to an appropriate amount of 50°C pure water, soak, expand and stir in the sol tank to dissolve the sodium alginate;

[0096] (2) Sol

[0097] Stir the above ingredients at a temperature of 75°C for 2.5 hours. After they are completely dissolved, add 5 g of hydroxymethyl starch, 2.5 g of glycerin and 2 g of titanium dioxide in sequence, and dissolve them completely to prepare a glue solution with a concentration of 13%.

[0098] (3) Raw glue

[0099] After stirring evenly, transfer to an automatic temperature-controlled stainless steel barrel for glue cultivation, keep warm at 30°C, and after standing for 7 hours, remove the surface foam. After the glue cultivation, the viscosity of the glue reaches 2500mPa.s;

[0100] (4) dipped in glue

[0101] After the glue cultivation is completed, un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com