Anti-aging shock resistant material and preparation method thereof as well as cable protection tube prepared from same

A cable protection tube and impact-resistant technology, applied in the field of cable protection tube materials, can solve the problems of heat resistance, low carrying capacity and thermal stability, insufficient electrical insulation performance, etc., achieve excellent anti-aging performance and improve smoke suppression effect , Improve the effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

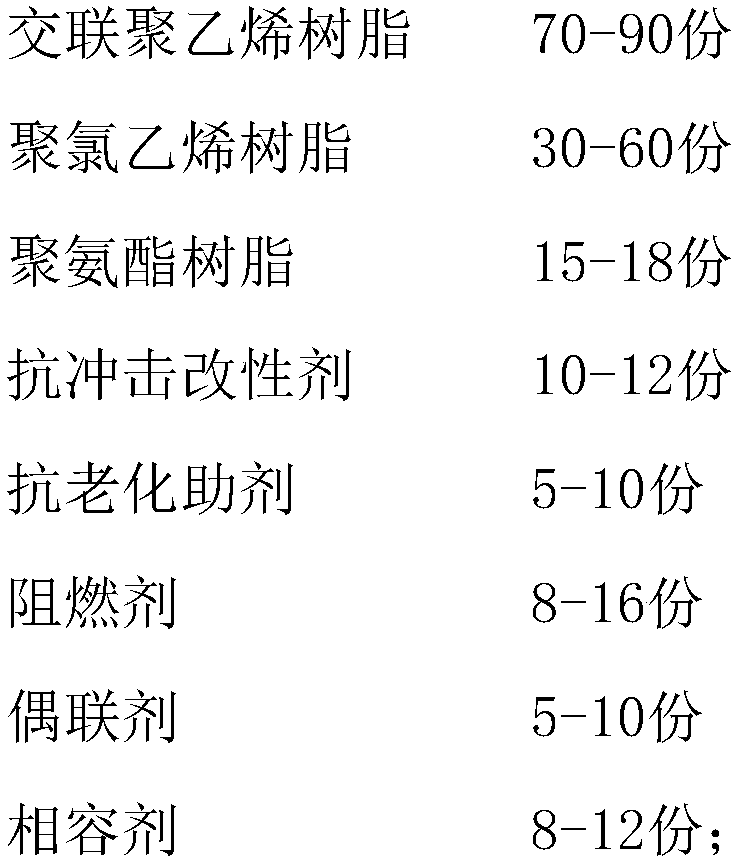

[0048] An anti-aging and impact-resistant material, comprising the following raw materials in parts by weight:

[0049]

[0050] The impact modifier is a mixture of silica filler and acrylate copolymer with a weight ratio of 1:3;

[0051] The anti-aging additive is a mixture composed of antioxidant A, light stabilizer, ultraviolet absorber and light shielding agent in parts by weight of 4:3:5:2.

[0052] The antioxidant A is antioxidant DLTP; the light stabilizer is light stabilizer 770; the ultraviolet absorber is ultraviolet absorber BAD; the light shielding agent is TiO 2 .

[0053] The silica filler is SiO 2 - A mixture of glass powder and glass flakes.

[0054] The flame retardant is a mixture of 2,4,6-tribromophenyl allyl ether and zinc borate.

[0055] The coupling agent is vinyltriethoxysilane; the compatibilizer is ethylene-acrylic acid-methyl ester grafted glycidyl methacrylate.

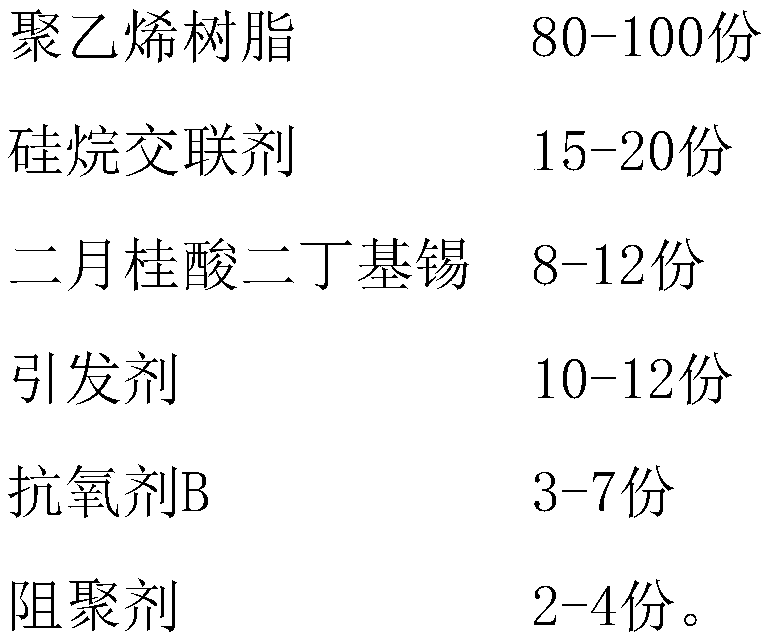

[0056] Described cross-linked polyethylene resin comprises the raw material of ...

Embodiment 2

[0066] The difference between this embodiment and above-mentioned embodiment 1 is:

[0067] An anti-aging and impact-resistant material, comprising the following raw materials in parts by weight:

[0068]

[0069] The impact modifier is a mixture of silica filler and acrylate copolymer with a weight ratio of 1.2:3.5;

[0070] The anti-aging additive is a mixture composed of antioxidant A, light stabilizer, ultraviolet absorber and light shielding agent in parts by weight of 4.5:4:4.5:2.5.

[0071] The antioxidant A is antioxidant CA; the light stabilizer is light stabilizer 944; the ultraviolet absorber is ultraviolet absorber 327; the light shielding agent is TiO 2 .

[0072] The silica filler is a mixture of glass flakes and glass fibers.

[0073] The flame retardant is a mixture of decabromodiphenylethane and zinc oxide.

[0074] The coupling agent is anilinomethyltriethoxysilane; the compatibilizer is hydrogenated styrene-butadiene-styrene copolymer grafted with gly...

Embodiment 3

[0086] The difference between this embodiment and above-mentioned embodiment 1 is:

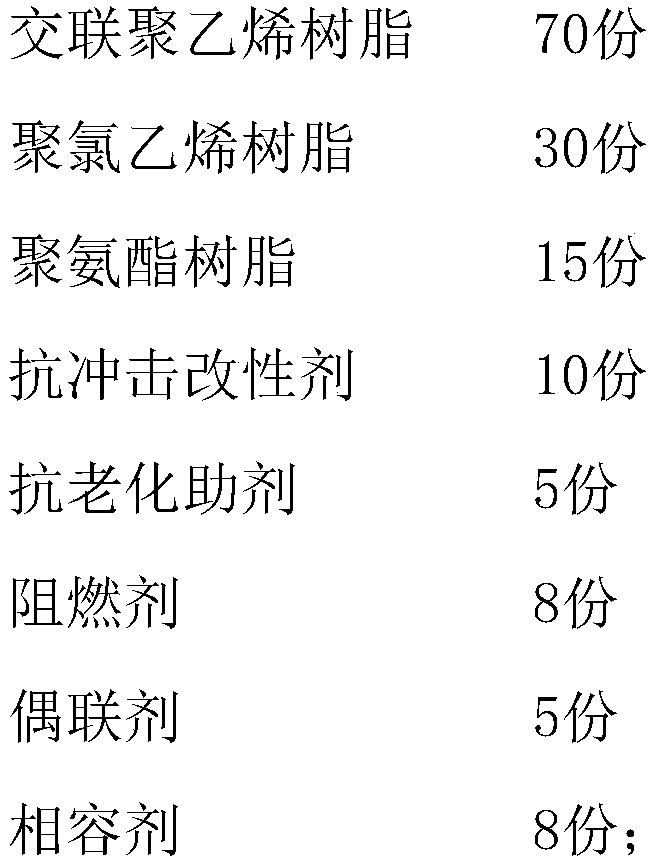

[0087] An anti-aging and impact-resistant material, comprising the following raw materials in parts by weight:

[0088]

[0089]

[0090] The impact modifier is a mixture of silica filler and acrylate copolymer with a weight ratio of 1.5:4;

[0091] The anti-aging additive is a mixture of antioxidant A, light stabilizer, ultraviolet absorber and light shielding agent in parts by weight of 5:5:4:3.

[0092] The antioxidant A is p-hydroxyanisole; the light stabilizer is light stabilizer 622; the ultraviolet absorber is ultraviolet absorber BAD; and the light shielding agent is ZnO.

[0093] The silica filler is SiO 2 - A mixture of glass powder and glass flakes.

[0094] The flame retardant is a mixture of decabromodiphenyl ether and antimony trioxide.

[0095] The coupling agent is methyltriethoxysilane; the compatibilizer is ethylene-acrylic acid-methyl ester grafted glycidyl methacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistivity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com