High-performance flame-retardant coating and preparation method thereof

A flame-retardant coating and high-efficiency technology, applied in the field of coatings, can solve the problems of complex coating process, coating aging and falling off, and high construction cost, and achieve the effects of improving high temperature resistance, high adhesion and improving reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

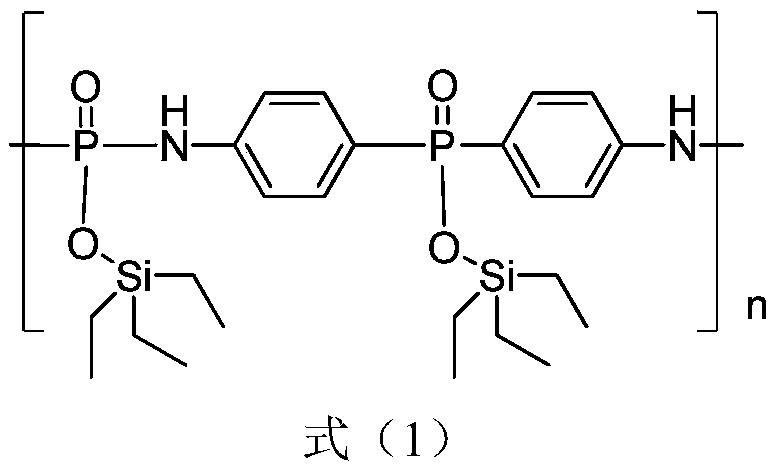

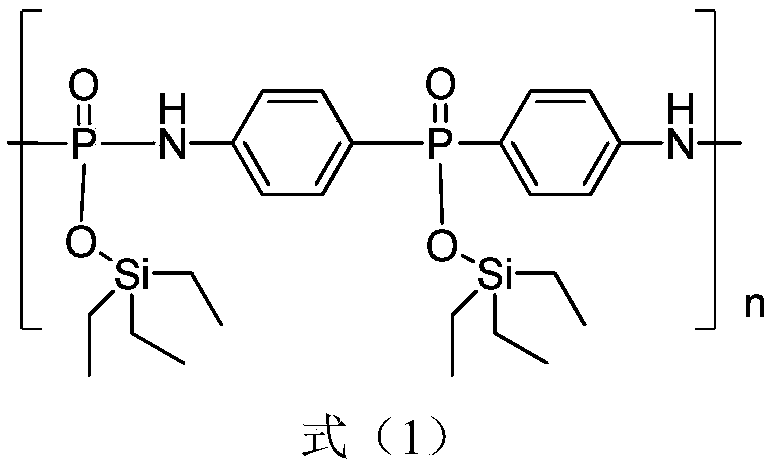

[0025] The preparation of embodiment 1 formula (1) polymkeric substance

[0026] Step 1: Weigh 1.5 mol dimethyl phosphonate into a reaction flask, add 100 mL of dichloromethane to dissolve, then pass nitrogen gas, add 0.5 mol triethylchlorosilane, react at room temperature for 3 hours, stop the reaction, wash with salt water for 3 hours times, dried over anhydrous magnesium sulfate;

[0027] Step 2: Weigh 1 mol of 4,4'-diaminophenyl phosphine hydroxy oxide into a reaction flask, add 100ml of dichloromethane to dissolve, then blow in nitrogen, add 0.5 mol of triethylchlorosilane, react at room temperature for 3 hours, stop reaction, washed with saline for 3 times, and dried over anhydrous magnesium sulfate;

[0028] Step 3: Weigh 1 mol of the result of step 1, 1 mol of the result of step 2 and 0.01 mol of triethylamine in a polymerization kettle and mix them uniformly, react at 370°C for 8 hours, stop the reaction, cool to room temperature, dry in vacuum, wash with water, dry ...

Embodiment 2

[0029] The preparation of embodiment 2 high-efficiency flame-retardant coatings

[0030] Weigh 1000g formula (1) polymer, 200g polyurethane resin, 150g melamine and 300g 200 # Add solvent oil into the reaction kettle, stir at 80-120°C for 30 minutes, cool down to 50-60°C, add 60g tricresyl phosphate, 60g carboxymethyl cellulose, 50g dimethyl phthalate, 15g silicone defoamer F202 and 8g 2,4,6-tri-tert-butylphenol, continue to stir at 50-60°C for 15-20 minutes, cool down to 45-55°C, add 100g attapulgite, 50g titanium dioxide and 120g antimony trioxide, Stir well and cool to room temperature.

Embodiment 3

[0031] The preparation of embodiment 3 high-efficiency flame-retardant coatings

[0032] Weigh 1200g formula (1) polymer, 250g polyurethane resin, 100g melamine and 400g 200 # Add solvent oil to the reaction kettle, stir at 80-120°C for 30 minutes, cool down to 50-60°C, add 80g tricresyl phosphate, 80g carboxymethyl cellulose, 80g dimethyl phthalate, 15g silicone defoamer F202 and 10g 2,4,6-tri-tert-butylphenol, continue stirring at 50-60°C for 15-20 minutes, cool down to 45-55°C, add 120g attapulgite, 60g titanium dioxide and 100g antimony trioxide, Stir well and cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com