Method and system for removing nitrite from slurry through simultaneous desulfurization and denitrification based on calcium-based quaternary ammonium salt catalyst

A quaternary ammonium salt, desulfurization and denitrification technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve secondary pollution, unsuitable for nitrite, difficult to remove nitrite, etc. To achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

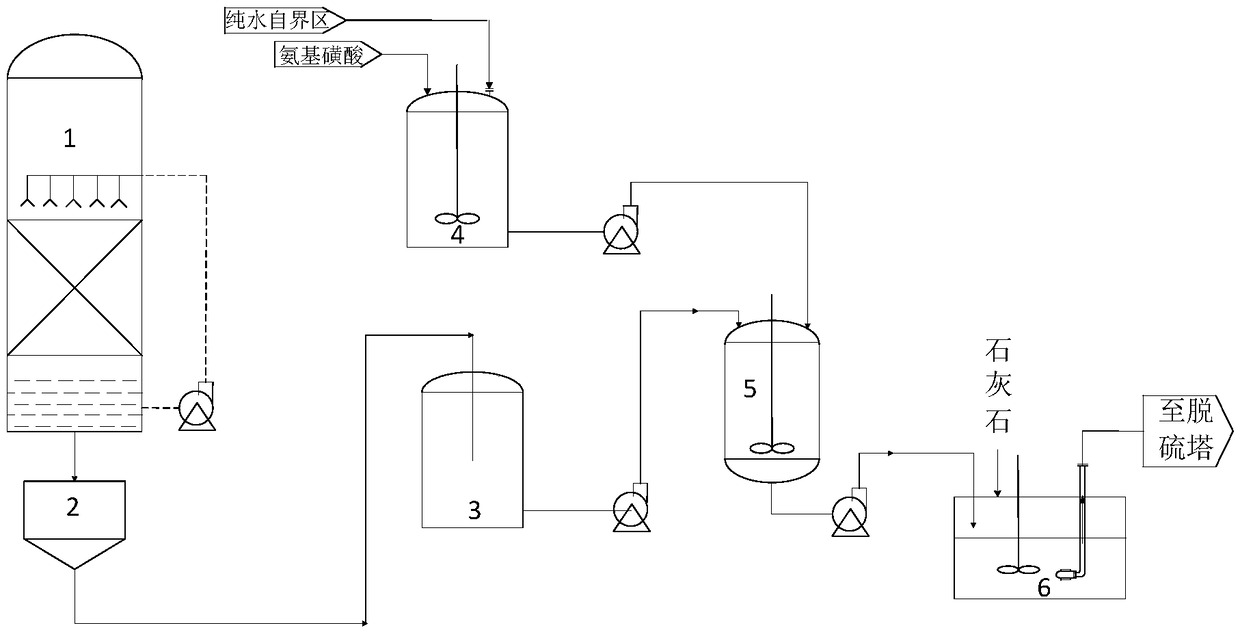

Image

Examples

Embodiment 1

[0047] In the sulfamic acid liquid mixing tank, a sulfamic acid solution with a concentration of 0.5% is first prepared, and the amount of the prepared sulfamic acid solution is adjusted according to the actual amount of the extracted slurry, and then transported to the reaction kettle. The filtrate in the filtrate buffer tank is injected into the reaction kettle through the solution pump, and the addition time is controlled at 30 minutes. When the slurry was added, the pH value during the reaction was detected by the pH meter installed on the reaction kettle, and it was observed that the pH value was stable in the range of 1.3 to 1.5, and the reaction temperature was detected to be 20°C. The exhaust gas above the reactor is drawn into the Rosemount flue gas analyzer, and the total amount of NOx released during the entire reaction process is continuously monitored to be below 8ppm. The liquid in the reaction kettle was sampled, and the nitrite in it was detected by naphthalene...

Embodiment 2

[0049] In the sulfamic acid liquid preparation tank, a sulfamic acid solution with a concentration of 1.5% is first prepared, and the amount of the prepared sulfamic acid solution is adjusted according to the actual amount of the extracted slurry, and then transported to the reaction kettle. The slurry in the filtrate buffer tank is injected into the reaction kettle through the solution pump, and the addition time is controlled at 90 minutes. When the slurry was added, the pH value during the reaction was detected by the pH meter installed on the reaction kettle, and it was observed that the pH value was stable in the range of 1.3 to 1.5, and the reaction temperature was detected to be 20°C. The exhaust gas above the reactor is drawn into the Rosemount flue gas analyzer, and the total amount of NOx released during the entire reaction process is continuously monitored to be below 15ppm. The liquid in the reaction kettle was sampled, and the nitrite in it was detected by naphtha...

Embodiment 3

[0051] In the sulfamic acid liquid preparation tank, a sulfamic acid solution with a concentration of 1.0% is first prepared, and the amount of the prepared sulfamic acid solution is adjusted according to the actual amount of the extracted slurry, and then transported to the reaction kettle. The slurry in the filtrate buffer tank is injected into the reaction kettle through the solution pump, and the addition time is controlled at 60 minutes. When the slurry was added, the pH value during the reaction was detected by the pH meter installed on the reaction kettle, and it was observed that the pH value was stable in the range of 1.3 to 1.5, and the reaction temperature was detected to be 20°C. The exhaust gas above the reactor is drawn into the Rosemount flue gas analyzer, and the total amount of NOx released during the entire reaction process is continuously monitored to be below 13ppm. The liquid in the reaction kettle was sampled, and the nitrite in it was detected by naphtha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com