Dimolybdenum carbide/titanium dioxide composite photocatalyst, and preparation method and application thereof

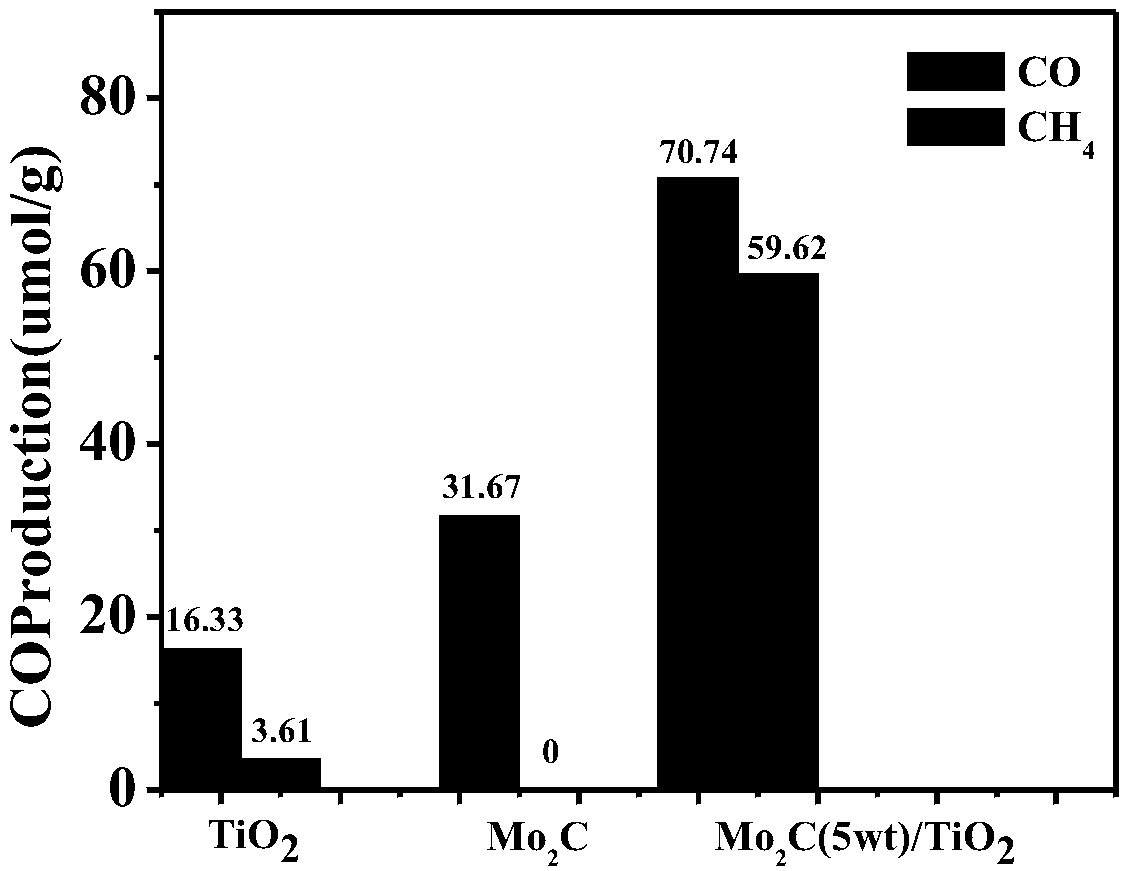

A technology of catalyst and composite light, which is applied in the direction of carbon compound catalysts, catalyst activation/preparation, and hydrocarbon production from carbon oxides. It can solve the problems of high cost and low catalytic activity, and achieve increased contact area, easy raw materials, and The effect of excellent photocatalytic CO2 reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

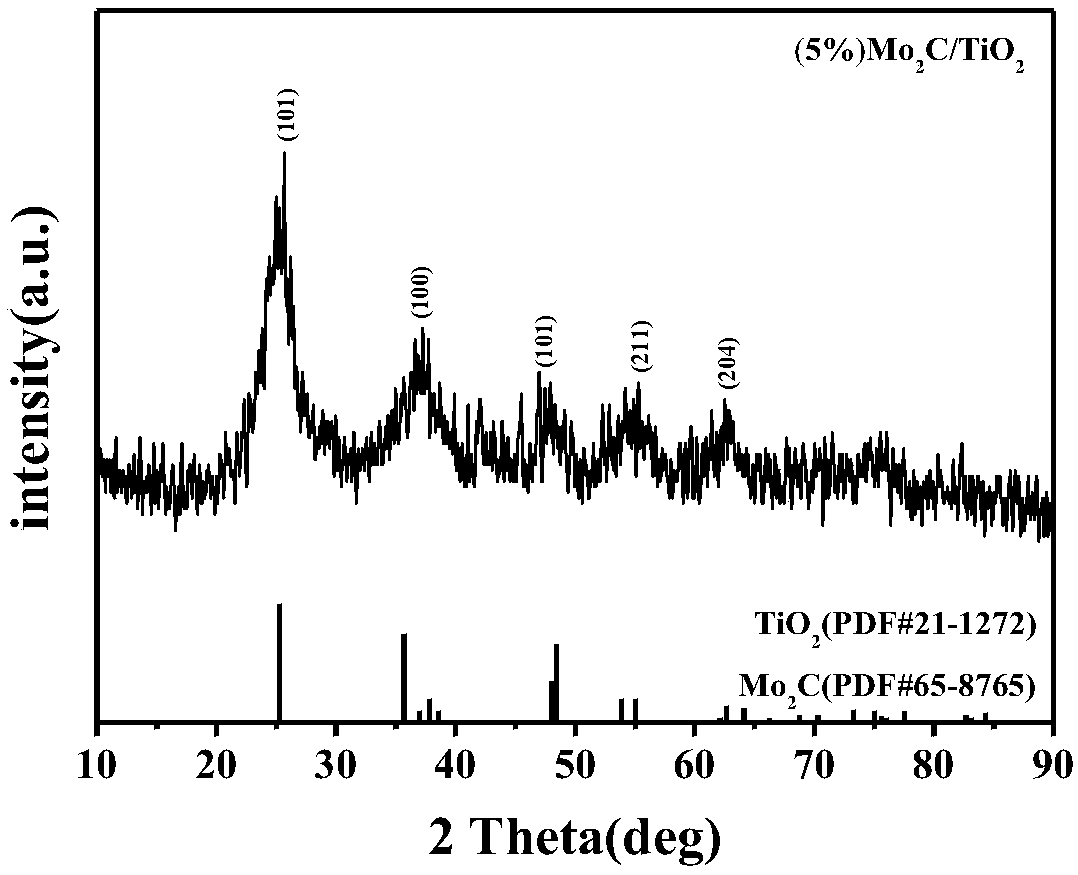

Embodiment 1

[0034] Step 1: Weigh 2.48g of ammonium heptamolybdate and dissolve it in a 250ml clean beaker filled with 40ml of deionized water, add 3.33ml of aniline, and then add 1mol / L hydrochloric acid dropwise (take 8.3ml concentrated hydrochloric acid and dilute to 100ml capacity bottle) while stirring until a small amount of white precipitate appeared. The solution containing a small amount of white precipitate was stirred in a water bath at 50°C for 5 hours (a large amount of white precipitate appeared), and after cooling down to room temperature, the large amount of white precipitate was washed 3 times with deionized water and 3 times with ethanol until neutral. Vacuum drying at a temperature of 50°C for 6 hours. After drying, use the high temperature carbonization method, and the flow rate is 50cm 3 / min95%Ar / 5%H 2 The mixed gas is kept at 20°C for 60 minutes to remove the air in the device, and then the temperature is raised to 725°C at a rate of 2°C / min and kept for 5 hours to...

Embodiment 2

[0038] Step 1: Weigh 2.48g of ammonium heptamolybdate and dissolve it in a 250ml clean beaker filled with 40ml of deionized water, add 3.33ml of aniline, and then add 1mol / L hydrochloric acid dropwise (take 8.3ml concentrated hydrochloric acid and dilute to 100ml capacity bottle) while stirring until a small amount of white precipitate appeared. The solution containing a small amount of white precipitate was stirred in a 50°C water bath for 2.5h (a large amount of white precipitate appeared), and after cooling down to room temperature, the large amount of white precipitate was washed 5 times with deionized water and 5 times with ethanol until neutral. Vacuum drying at 70°C for 4 hours. After drying, use the high temperature carbonization method, and the flow rate is 50cm 3 / min95%Ar / 5%H 2 The mixed gas is kept at 20°C for 60 minutes to remove the air in the device, and then the temperature is raised to 850°C at a rate of 2°C / min and kept for 5 hours to obtain Mo 2 C; treat ...

Embodiment 3

[0042] Step 1: Weigh 2.48g of ammonium heptamolybdate and dissolve it in a 250ml clean beaker filled with 40ML of deionized water, add 2.22ml of aniline, then add 1mol / L hydrochloric acid dropwise (take 8.3ml concentrated hydrochloric acid and dilute to 100ml capacity bottle) while stirring until a small amount of white precipitate appeared. The solution containing a small amount of white precipitate was stirred in a water bath at 50°C for 5 hours (a large amount of white precipitate appeared), and after cooling down to room temperature, the large amount of white precipitate was washed 3 times with deionized water and 3 times with ethanol until neutral. Vacuum drying, temperature 60 ° C, time 5h. After drying, use the high temperature carbonization method, and the flow rate is 50cm 3 / min95%Ar / 5%H 2 Mixed gas, kept at 20°C for 60min, then raised to 700°C at a rate of 2°C / min and kept for 5h, to obtain Mo 2 C; treat it in 95%Ar / 5%H 2 Cool to room temperature in a mixed gas,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com