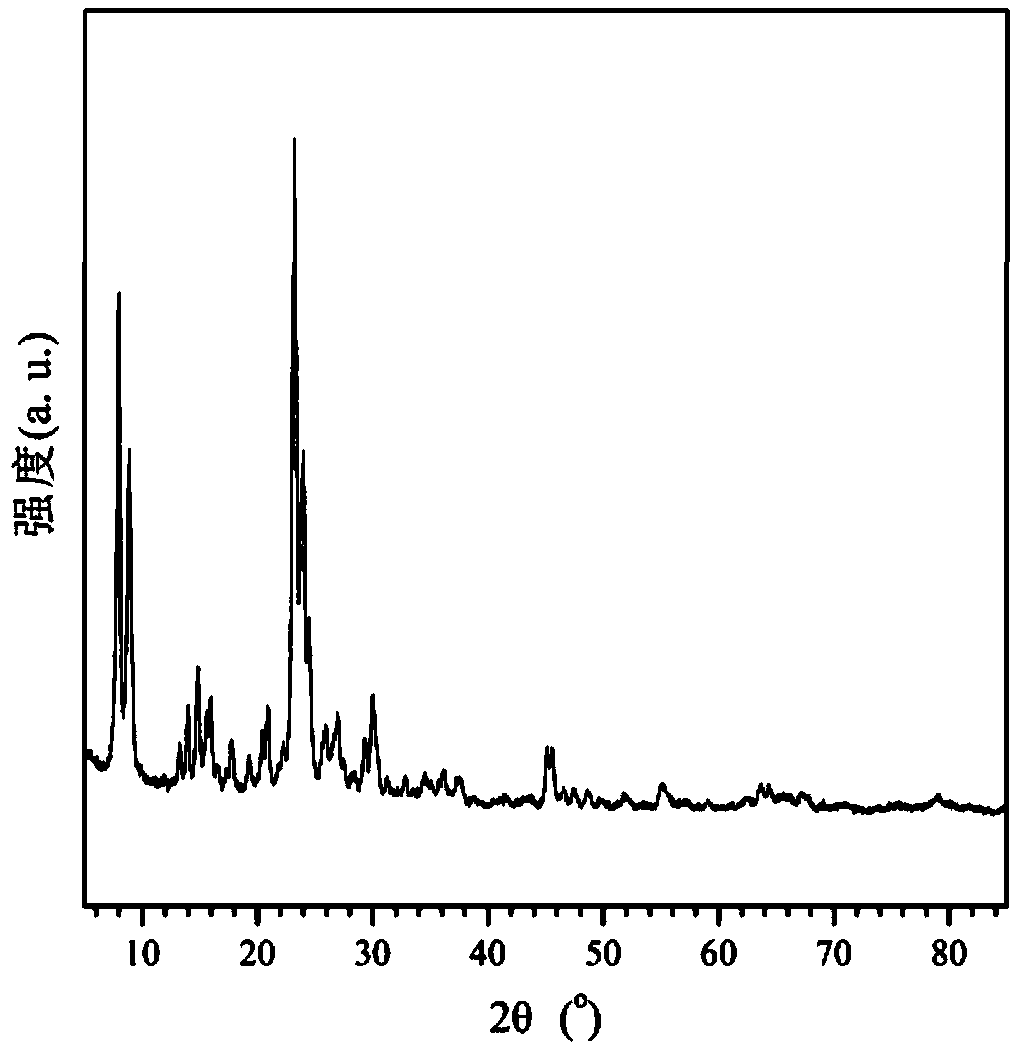

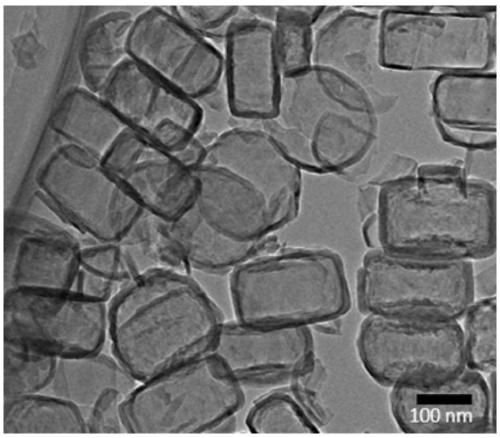

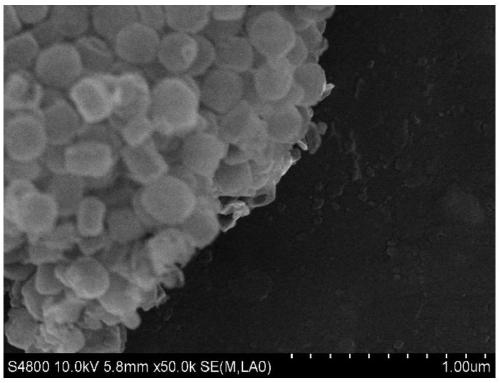

Nanometer hollow H type ZSM-5 molecular sieve, and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of catalytic performance degradation, catalytic activity deactivation, deactivation, etc., and achieve a solution Easy to deposit carbon, improve adsorption characteristics, and reduce contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of nanometer hollow H type ZSM-5 molecular sieve, carries out according to the following steps:

[0022] 1. Taking tetraethyl orthosilicate as silicon source, sodium metaaluminate as aluminum source, and tetrapropyl ammonium hydroxide as organic template; wherein the molar ratio of silicon source, aluminum source, organic template and water is 1: (0.01~0.04):(0.1~0.4):(5~15).

[0023] 2. Dissolve tetraethyl orthosilicate and sodium metaaluminate in deionized water to form a clear solution, slowly add tetrapropylammonium hydroxide to the solution, and stir at 30-50°C for 4-6h.

[0024] 3. Transfer the above solution to a reaction kettle lined with polytetrafluoroethylene, first crystallize at 100-140°C for 2-4 hours, then crystallize at 170-200°C for 18-24 hours, then cool to room temperature, and centrifuge Wash until neutral, dry in an oven at 100°C, place in a muffle furnace, heat up to 400-600°C and bake for 5-10 hours to obtain Na-type ZSM-5 ...

Embodiment 1

[0029] The preparation method of nanometer hollow H type ZSM-5 molecular sieve, carries out according to the following steps:

[0030] 1. Weigh 15.6 g of tetraethyl orthosilicate, 0.123 g of sodium metaaluminate, 12.18 g of tetrapropyl ammonium hydroxide solution with a mass fraction of 25%, and 7 g of deionized water.

[0031] 2. Dissolve tetraethyl orthosilicate and sodium metaaluminate in deionized water according to the amount weighed above to form a clear solution, slowly add tetrapropylammonium hydroxide to the solution, and stir at 30°C for 6h.

[0032] 3. Transfer the solution obtained in step 2) to a reaction kettle lined with polytetrafluoroethylene, first crystallize at 120°C for 2h, then crystallize at 170°C for 24h, then cool to room temperature, and use a 6000r / min centrifuge Centrifuge and wash with deionized water until neutral, oven-dried at 100°C, place in a muffle furnace, heat up to 550°C and roast for 6 hours to obtain Na-type ZSM-5 powder;

[0033] 4. Pu...

Embodiment 2

[0041] Example 2: The only difference between this embodiment and Example 1 is that the mixing and stirring time of the silicon source, the aluminum source, and the template agent in step 2 is 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| External area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com