Pretreatment method of improving dewatering performance of urban sludge

A sludge dewatering and pretreatment technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Follow-up treatment volume and other issues to achieve the effect of reducing capillary water and bound water, reducing specific resistance and viscosity, and increasing interstitial water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

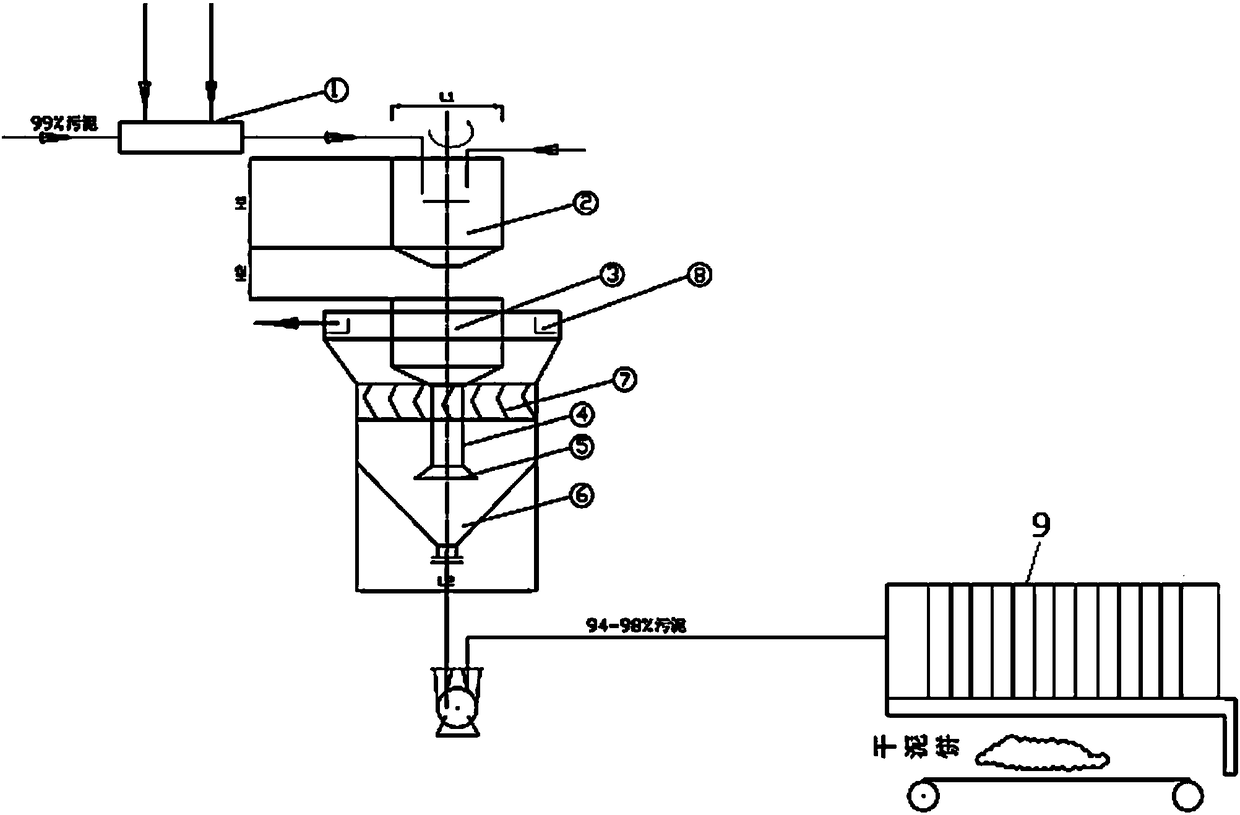

Image

Examples

Embodiment 1

[0043] In this embodiment, the remaining activated sludge with a water content of 98 wt.% in the secondary settling tank of a sewage plant is taken as an example to illustrate the pretreatment method of the present invention, which includes the following steps:

[0044] (1) Reduction and coagulation step: The remaining activated sludge with a water content of 98 wt.% in the secondary settling tank of the sewage treatment plant is pumped by a sludge pump, and through the sub-pipe mixer in front, a drying-type sulfuric acid with a concentration of 20 wt.% is added Ferrous solution is added according to 0.4% (w / w) of the total weight of wet sludge, mixed and reacted for 3 seconds to obtain sludge with a PH value of 4.8;

[0045] At the dosing port of the latter sub-pipe mixer, add a membrane breaker. The membrane breaker is hydrogen peroxide. The dosage is 0.2% (w / w) of the wet sludge, and the concentration of hydrogen peroxide is 15wt.%. The reaction is 7s, then , The sludge is disch...

Embodiment 2

[0052] In this embodiment, the remaining activated sludge with a water content of 99wt.% in the secondary settling tank of a sewage plant is taken as an example to illustrate the pretreatment method of the present invention, which includes the following steps:

[0053] (1) Reduction and coagulation step: the remaining activated sludge with a water content of 99 wt.% in the secondary settling tank of the sewage treatment plant is pumped by a sludge pump, and then through the sub-pipe mixer at the front end, adding 15 wt.% drying type sulfuric acid The iron solution is added at 0.2% (w / w) of the total weight of the wet sludge, mixed and reacted for 2 seconds to obtain sludge with a pH of 5.2;

[0054] (2) At the inlet of the latter sub-pipe mixer, add a membrane breaker. The membrane breaker is hydrogen peroxide. The dosage is 0.1% (w / w) of the amount of wet sludge, the concentration of hydrogen peroxide is 10wt%, and the mixing time is 5s. Discharge the sludge into the high-level mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com