Method for preparing electromagnetic shielding flame-retardant fiberboard

A flame-retardant fiber and electromagnetic shielding technology, which is applied in the field of decorative materials, can solve the problems of lack of electromagnetic shielding effect and poor water resistance, and achieve the effects of improving internal bonding strength, isolating oxygen flame-retardant area, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

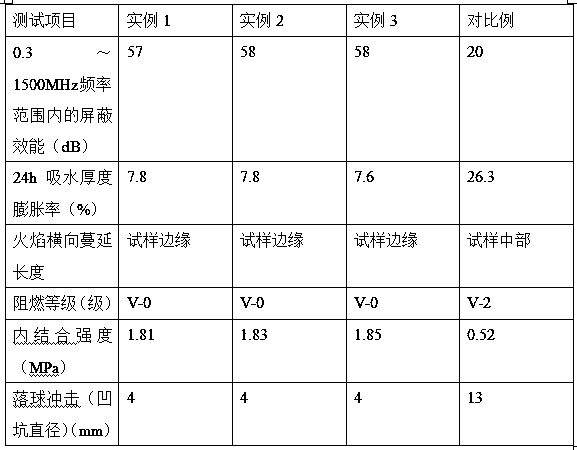

Examples

Embodiment Construction

[0023]Mix rice straw and bean straw with a mass ratio of 1:5, put them into a pulverizer and pulverize them for 4 to 5 hours, pass through a 200-mesh sieve to obtain fiber scraps, take trimethylmethoxysilane with 2% mass of fiber scraps, and use Dissolve trimethylmethoxysilane in acetone to prepare a trimethylmethoxysilane solution with a mass fraction of 5%, mix fiber scraps and burned rice husk ash at a mass ratio of 5:1, and then impregnate Soak in trimethylmethoxysilane solution at room temperature for 4-5 hours, filter, remove the filtrate to obtain modified fiber scraps, and set aside; add 100-120g ammonium polyphosphate, 230-250mL absolute ethanol, 100-200mL distilled water, stir and mix for 20-25min, continue to add ammonia water with a mass fraction of 35% to the beaker to adjust the pH to 10.2-10.4, to obtain retardant fuel, add 20-25g methyl triethoxy to the retardant fuel For silane, heat the beaker in a water bath to 45-60°C, keep it warm for 2-3 hours, filter and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com