A kind of bacterial cellulose facial mask with antioxidant capacity and preparation method thereof

A technology of bacterial cellulose and anti-oxidation ability, applied in biochemical equipment and methods, methods based on microorganisms, medical preparations containing active ingredients, etc., can solve the problems affecting the large-scale industrial production of bacterial cellulose and the carbon source of culture medium High cost, unsatisfactory effect and other problems, to achieve the effect of high value utilization, inhibition of formation and deposition, and good inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

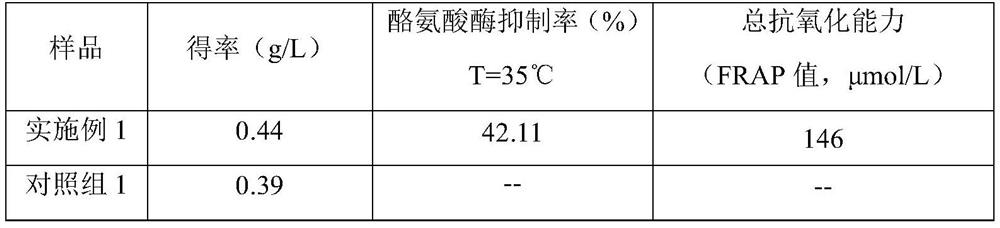

Embodiment 1

[0037] Take 5g of pure milk, 0.1g of tea polyphenols, 5g of mannitol, 5g of peptone, 5g of yeast powder, MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O 1g, adjust the pH value to 6.8 with 0.1mol / L NaOH and 0.1mol / L HCl solution, put it in a high-temperature sterilization pot at 121°C for 20min, cool it until it is not hot, add 5ml of absolute ethanol, Continue cooling to room temperature to obtain a fermentation medium. Take 100ml of fermentation medium and put it into 250ml sterilized Erlenmeyer flasks, let it stand for 12 hours, and it can be used only if no bacteria grow out. The activated Acetobacter xylinum suspension (about 1 × 10 7 cells / mL) were inoculated on the aliquoted fermentation medium in an amount of 5% (v / v), and cultured in a constant temperature and humidity chamber at 30° C. for 5 days.

[0038] Control group 1: take glucose 5g, mannitol 5g, peptone 5g, yeast powder 5g, MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O 1g, ...

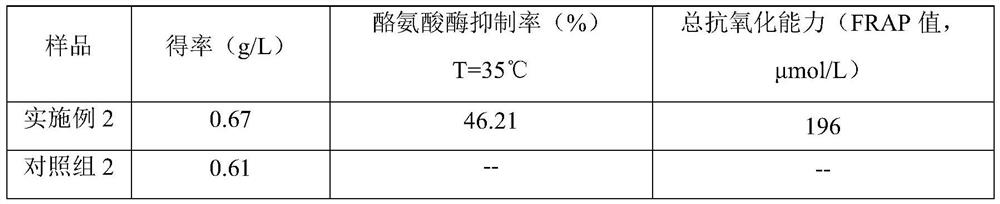

Embodiment 2

[0043] Take 30 days expired pure milk 10g, tea polyphenols 0.2g, mannitol 5g, peptone 5g, yeast powder 5g, MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O 1g, adjust the pH value to 6.8 with 0.1mol / L NaOH and 0.1mol / L HCl solution, put it in a high-temperature sterilization pot at 121°C for 20min, cool it until it is not hot, add 5mL of absolute ethanol, Continue to cool to room temperature. Take 100mL of fermentation medium and put it into 250mL sterilized Erlenmeyer flasks, let it stand for 12h, and use it when no bacteria grow out. The activated Acetobacter xylinum suspension (about 1 × 10 7 cells / mL) were inoculated on the aliquoted fermentation medium in an amount of 5% (v / v), and cultured in a constant temperature and humidity chamber at 30° C. for 5 days.

[0044] Control group 2: Take glucose 10g, mannitol 5g, peptone 5g, yeast powder 5g, MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O 1g, adjust the pH value to 6.8 with 0.1mol / L NaOH...

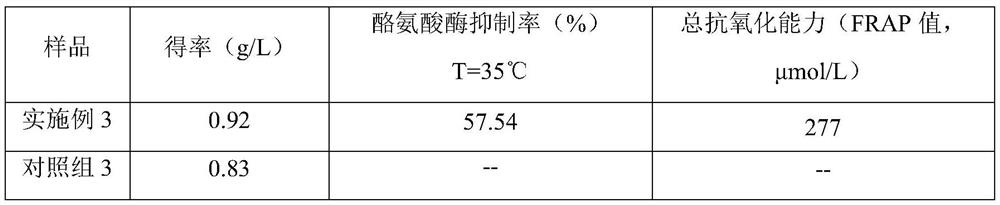

Embodiment 3

[0049] Take 15g of 30-day-expired pure milk, 0.3g of tea polyphenols, 5g of mannitol, 5g of peptone, 5g of yeast powder, and MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O 1g, adjust the pH value to 6.8 with 0.1mol / L NaOH and 0.1mol / L HCl solution, put it in a high-temperature sterilization pot at 121°C for 20min, cool it until it is not hot, add 5mL of absolute ethanol, Continue cooling to room temperature to obtain a fermentation medium. Take 100mL of fermentation medium and put it into 250mL sterilized Erlenmeyer flasks, let it stand for 12h, and use it when no bacteria grow out. The activated Acetobacter xylinum suspension (about 1 × 10 7 cells / mL) were inoculated on the aliquoted fermentation medium in an amount of 5% (v / v), and cultured in a constant temperature and humidity chamber at 30° C. for 5 days.

[0050] Control group 3: take glucose 10g, mannitol 5g, peptone 5g, yeast powder 5g, MgSO 4 ·7H 2 Add 1000mL of distilled water to fully dissolve O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com