Method for preparing graphene single crystal wafer at low temperature

A technology of graphene and single crystals, which is applied in the field of low-temperature preparation of graphene single crystal wafers, can solve the problems of graphene single crystal wrinkles, achieve good crystallinity, consistent orientation, and reduce wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

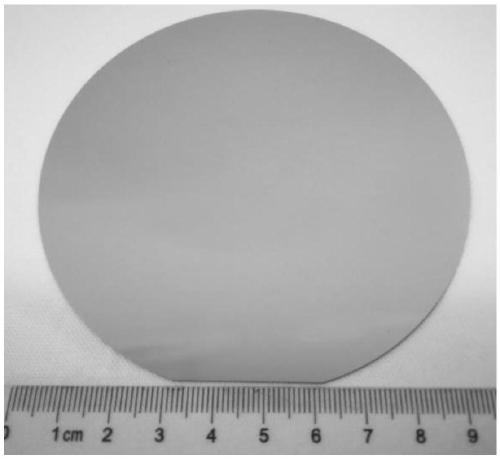

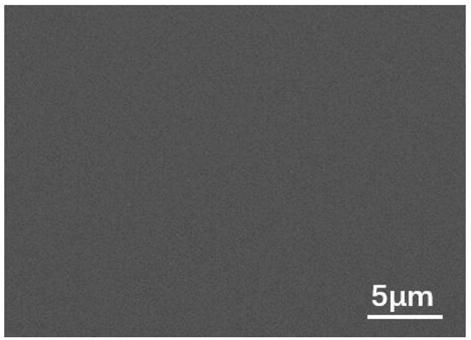

[0037] Sapphire was selected as the substrate, and nickel-copper alloy thin films were prepared by magnetron sputtering. The sputtering is carried out under the conditions of high-purity argon gas and a vacuum of 0.5 Pa, and the sputtering rate is 5 nm / min. A 50nm copper-nickel alloy substrate is deposited on the surface of a sapphire substrate (at a temperature of 50° C.) by magnetron sputtering, wherein the content of nickel element is 5%. The film is placed in a chemical vapor deposition system, and annealed in an argon and hydrogen protective atmosphere, wherein the flow rate of argon and hydrogen is 400sccm: 10sccm, the annealing temperature is 750°C, the annealing time is 60min, and then 10sccm methane is introduced , grown for 60 min, and grown under normal pressure to obtain a graphene single crystal wafer. By Raman (eg Figure 5 Shown) It can be seen that the quality of graphene is relatively high, and there are no defect peaks in the Raman peak of graphene.

[003...

Embodiment 2

[0044] Change the copper-nickel alloy substrate in embodiment 1 to a copper-platinum alloy substrate, wherein the platinum element content is 5%, the growth temperature is changed to 600 ° C, and the rest of the process parameters are the same as in embodiment 1 to obtain a graphene single crystal wafer, Raman spectrum such as Image 6 As shown, it can be seen that at ~1600cm -1 And ~ 2700cm -1 Graphene characteristic peak appears at 1400cm -1 No defect peaks were found at , confirming that the quality of the grown graphene is relatively high.

[0045] Figure 10 It shows that there are six bright points in the figure, indicating that the graphene is in the same orientation and is single crystal graphene.

Embodiment 3

[0047] Change the copper-nickel alloy substrate in Example 1 to a copper-palladium alloy substrate, wherein the palladium element content is 10%, the growth temperature is changed to 500 ° C, and the growth pressure is 10 -10 Pa, the carbon source is changed into ethylene, and all the other process parameters are identical with embodiment 1, obtain graphene single crystal wafer, and Raman collection of illustrative plates is as follows Figure 7 As shown, it can be seen that at ~1600cm -1 And ~ 2700cm -1 Graphene characteristic peak appears at 1400cm -1 No defect peaks were found at , confirming that the quality of the grown graphene is relatively high.

[0048] Figure 11 It shows that the graphene spots are six-fold symmetric and have the same orientation, which is a graphene single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com