Modified MXenes powder as well as preparation method and application thereof

A modification and powder technology, applied in the direction of carbide, titanium carbide, etc., can solve the problems of affecting wettability, reducing thermal and electrical conductivity, and negative impact on the performance of metal matrix composite materials, so as to improve interface bonding characteristics and improve mechanical properties. The effect of simple characteristics and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

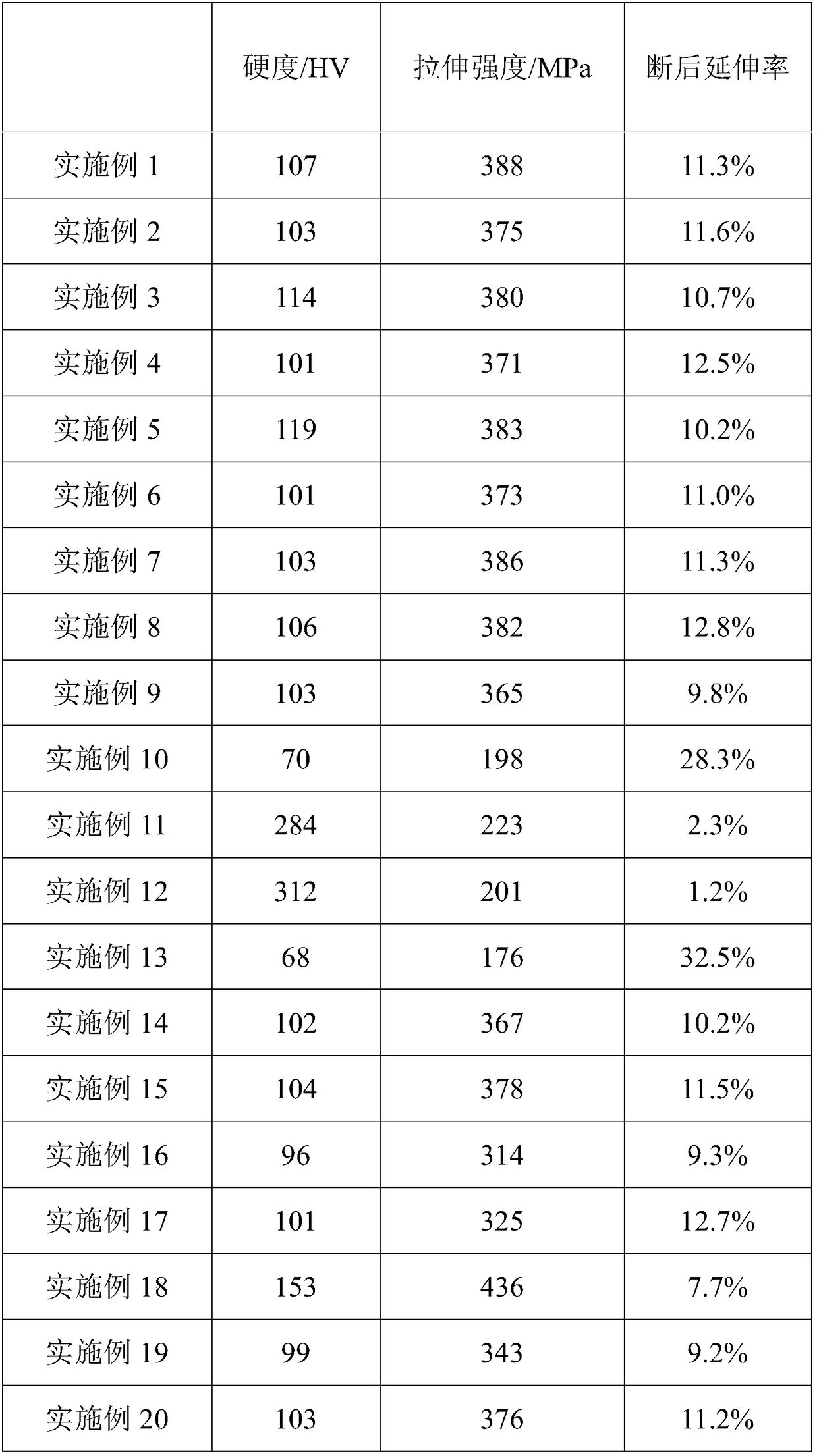

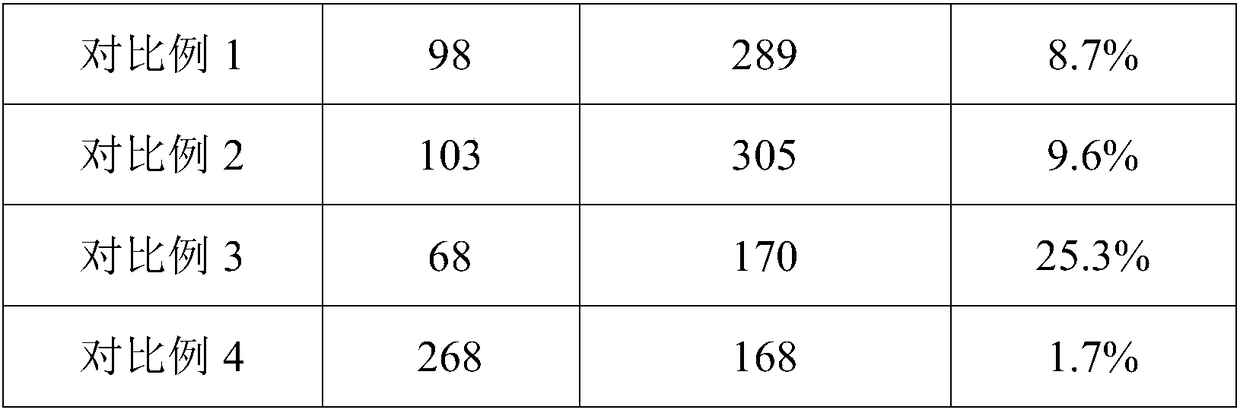

Examples

Embodiment 1

[0082] A method for preparing a metal matrix composite material comprises the following steps:

[0083] (1) Preparation of modified MXenes powder

[0084] Electrochemical intercalation of Ti 3 C 2 For metal ion intercalation, the platinum electrode is used as the anode, and the 5.0gTi coated with the ion exchange membrane 3 C 2 The powder is the cathode, with 1.0mol / L Ni(Cl) 2 As the electrolyte, under 0.5V DC voltage, for Ti 3 C 2 The powder was intercalated with metal ions for 40 minutes, and the intercalated Ti 3 C 2 The powder was vacuum-dried at 60°C, 2 atmosphere, annealing at 800°C to obtain a modified Ti with a content of 4% of nano-nickel particles 3 C 2 Powder.

[0085] (2) Preparation of metal matrix composites

[0086] (a) Weigh 5g modified Ti 3 C 2 The powder and 45g of copper powder are added into 150ml of 50vol% ethanol to form a mixed slurry, and the mixed slurry is ultrasonically heated and stirred for 1.5h at the same time (the power density of ...

Embodiment 2

[0089] The difference with Example 1 is that in step (1), the intercalation time is 30min, and the modified Ti with a nano-nickel particle content of 3% is obtained. 3 C 2 Powder.

Embodiment 3

[0091] The difference with Example 1 is that in step (1), the intercalation time is 60min, and the modified Ti with a nano-nickel particle content of 5% is obtained. 3 C 2 Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com