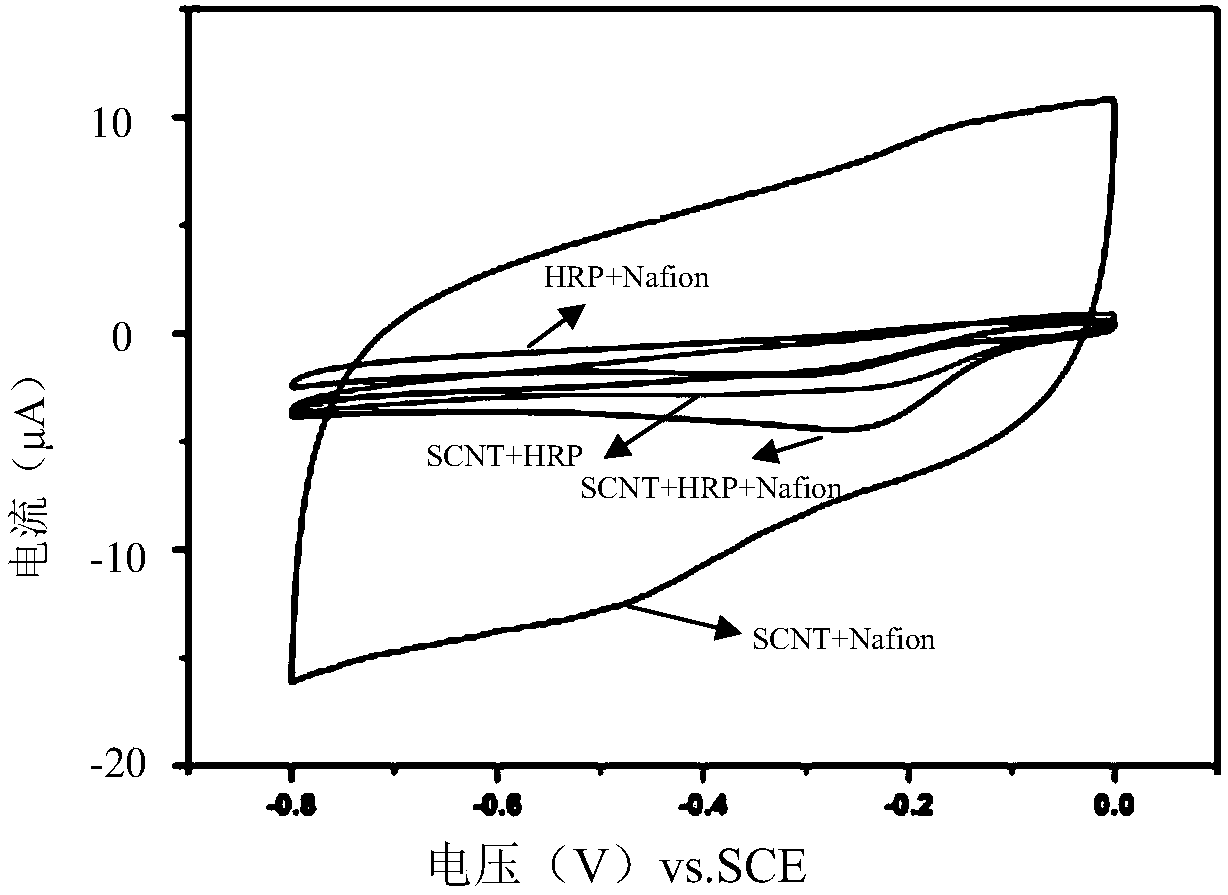

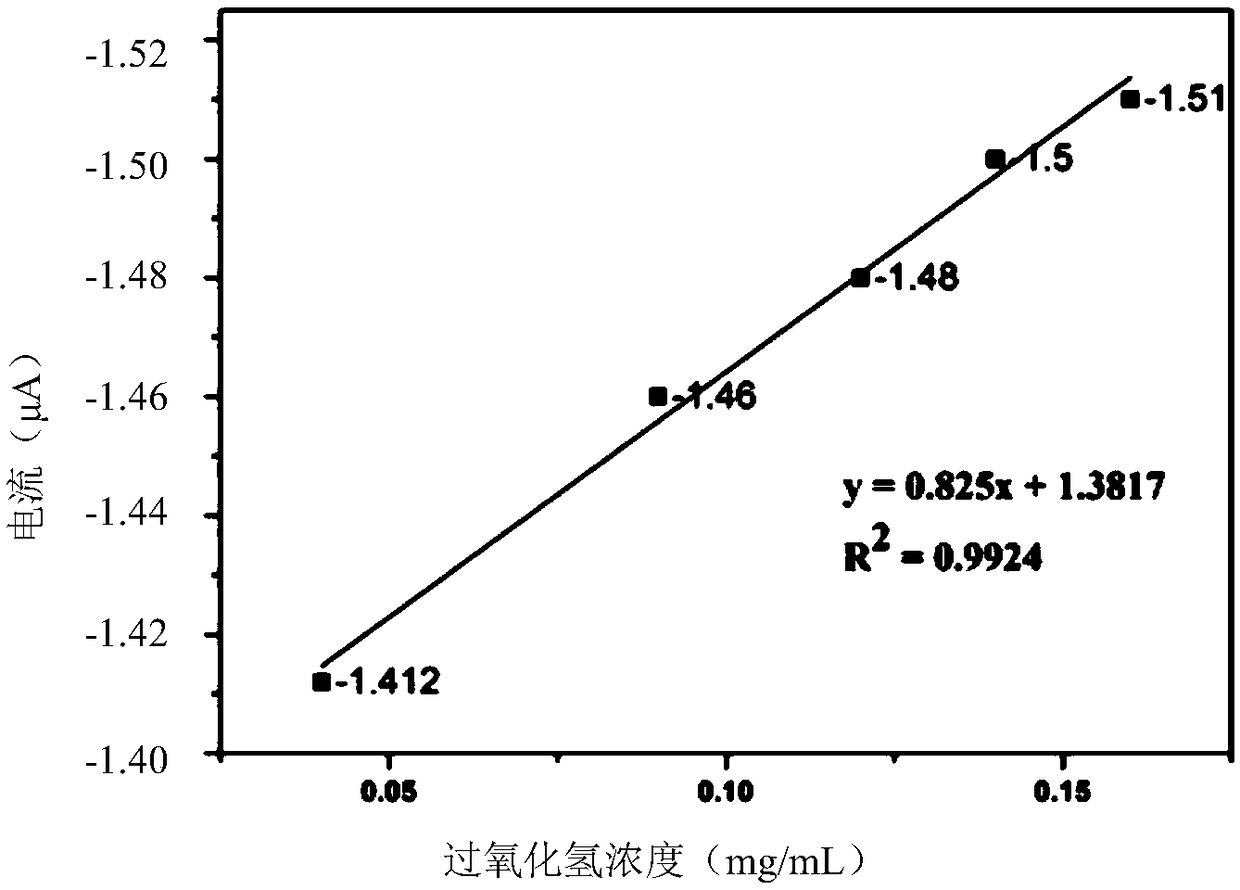

Hydrogen peroxide biosensor based on sulfonated carbon nanotube composited with horseradish peroxidase, preparation and application thereof

A composite technology of horseradish peroxidase and nanotubes, which is applied in the direction of instruments, scientific instruments, and electrochemical variables of materials, can solve the problems of unfavorable non-pollution detection of the system to be tested, unfavorable hydrogen peroxide sensors, etc., and achieve good application Foreground, improvement of hydrophilicity, effect of good electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a hydrogen peroxide biosensor based on sulfonated carbon nanotube composite horseradish peroxidase, comprising the following steps:

[0045] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0046] (2) Place 100 mg of acidified carbon nanotubes (acidified carbon nanotubes) in 100 mL of distilled water for ultrasonic dispersion for 30 minutes to obtain a suspension of 1 mg / mL acidified carbon nanotubes; dissolve 72 mg of sodium nitrite in 40 mL of distilled water, Cool to 0-5°C to obtain an aqueous solution of sodium nitrite; then add 184mg of p-aminobenzenesulfonic acid and 2g of hydrochloric aci...

Embodiment 2

[0052] A method for preparing a hydrogen peroxide biosensor based on sulfonated carbon nanotube composite horseradish peroxidase, comprising the following steps:

[0053] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0054] (2) Put 100 mg of acidified carbon nanotubes into 100 mL of distilled water for 30 minutes to obtain a suspension of 1 mg / mL acidified carbon nanotubes; dissolve 72 mg of sodium nitrite in 40 mL of distilled water and cool to 0-5°C , then 184mg p-aminobenzenesulfonic acid and 2g hydrochloric acid aqueous solution (1mol / L) were added into the sodium nitrite aqueous solution and mixed evenly, and ice-bat...

Embodiment 3

[0063] A method for preparing a hydrogen peroxide biosensor based on sulfonated carbon nanotube composite horseradish peroxidase, comprising the following steps:

[0064] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0065] (2) Put 100 mg of acidified carbon nanotubes into 100 mL of distilled water for 30 minutes to obtain a suspension of 1 mg / mL acidified carbon nanotubes; dissolve 72 mg of sodium nitrite in 40 mL of distilled water and cool to 0-5°C , followed by adding 184mg p-aminobenzenesulfonic acid and 2g hydrochloric acid aqueous solution (1mol / L) into the sodium nitrite aqueous solution and uniformly mixing, ice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com