Silver-manganese oxide composite catalyst and preparation method and application thereof

A composite catalyst, manganese oxide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of difficult controllable synthesis, high cost and preparation of catalyst The method is complex and other problems, to achieve the effects of strong controllability of the preparation process, simple preparation method and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The specific embodiment part of the present invention provides a kind of preparation method of silver manganese oxide composite catalyst, described method comprises the following steps:

[0045] (1) Add alkaline solution to manganese source and silver source mixed solution, react to generate solid precipitation;

[0046] (2) Calcining the solid precipitate obtained in step (1) to obtain a silver-manganese oxide composite catalyst.

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of silver manganese oxide composite catalyst, described method comprises the following steps:

[0050] (1) be that manganese nitrate and silver nitrate that mol ratio is 14:1 are dissolved in water, form mixed solution, drip excess sodium carbonate solution under stirring condition, reaction generates manganese carbonate and silver carbonate mixed solid precipitation;

[0051] (2) Wash the mixed solid precipitate obtained in step (1) until neutral, dry at 120° C., and then calcinate at 600° C. for 3 hours to obtain a silver-manganese oxide composite catalyst.

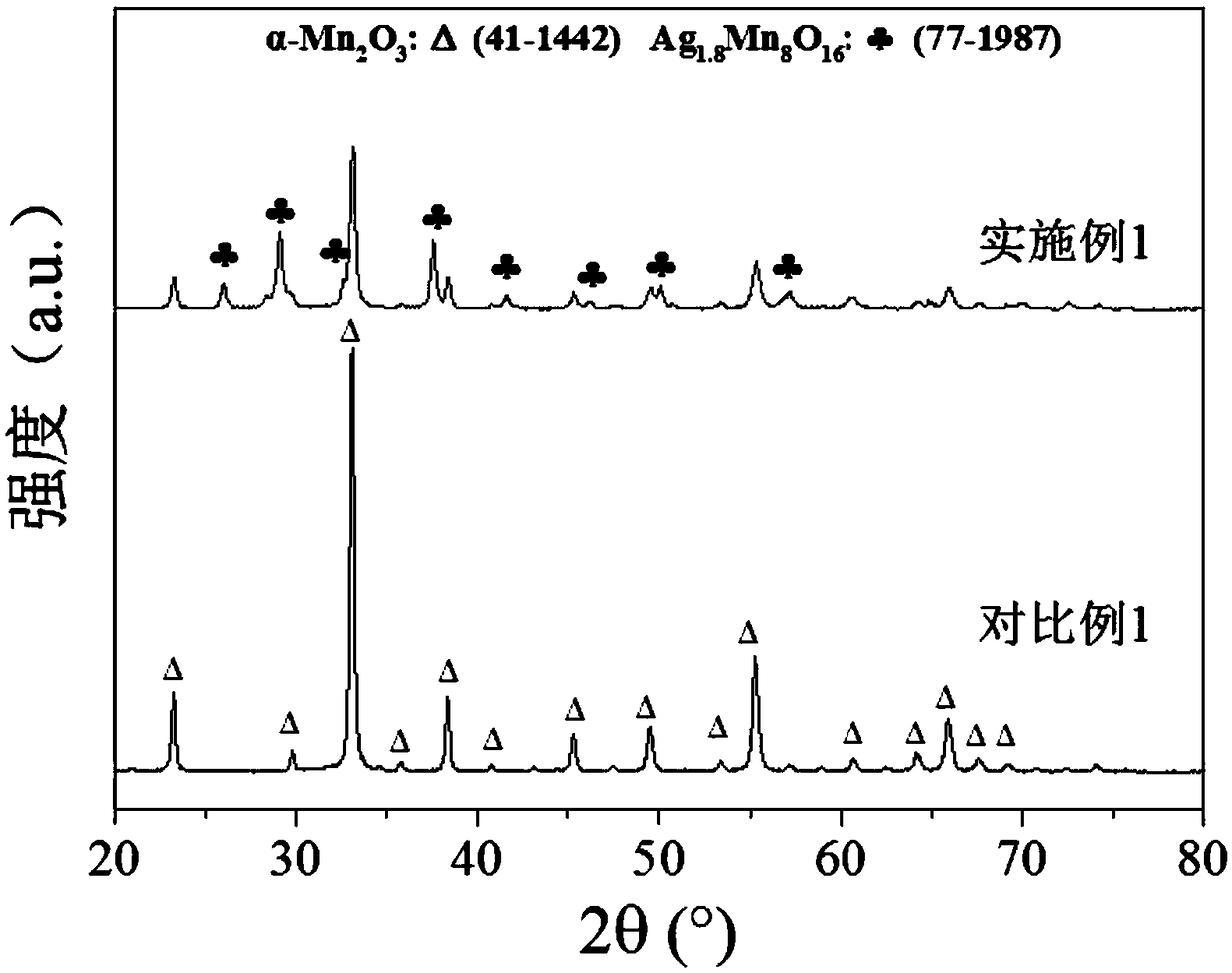

[0052] The silver-manganese oxide composite catalyst that is prepared is carried out X-ray diffraction (XRD) analysis, the result is as follows figure 1 Shown; The catalyst is carried out ozonolysis performance test, and concrete test condition is: ozone concentration is 40ppm, and test temperature is 30 ℃, and relative humidity is 70%, and reaction spa...

Embodiment 2

[0055] The present embodiment provides a kind of preparation method of silver manganese oxide composite catalyst, described method comprises the following steps:

[0056] (1) Manganese sulfate and silver nitrate with a mol ratio of 14:1 are dissolved in water to form a mixed solution, and excessive potassium carbonate solution is added dropwise under stirring conditions, and the reaction generates a mixed solid precipitation;

[0057] (2) Washing the mixed solid precipitate obtained in step (1) until neutral, drying at 90° C., and calcining at 300° C. for 5 hours to obtain a silver-manganese oxide composite catalyst.

[0058] The prepared silver-manganese oxide composite catalyst was subjected to an ozonolysis performance test, and the specific test conditions were referred to in Example 1.

[0059] In this example, the mass fraction of silver in the obtained catalyst was 8 wt%. After the ozone decomposition performance test, under the above test conditions of high space veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com