Preparation method of novel biodegradable rapid light curing molding material

A light-curing molding and biodegradation technology, applied in the field of material preparation, can solve the problems of ion toxicity residue, carbon-carbon double bond remaining difficult to degrade, etc., and achieve the effects of low price, high mechanical properties, and good degradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

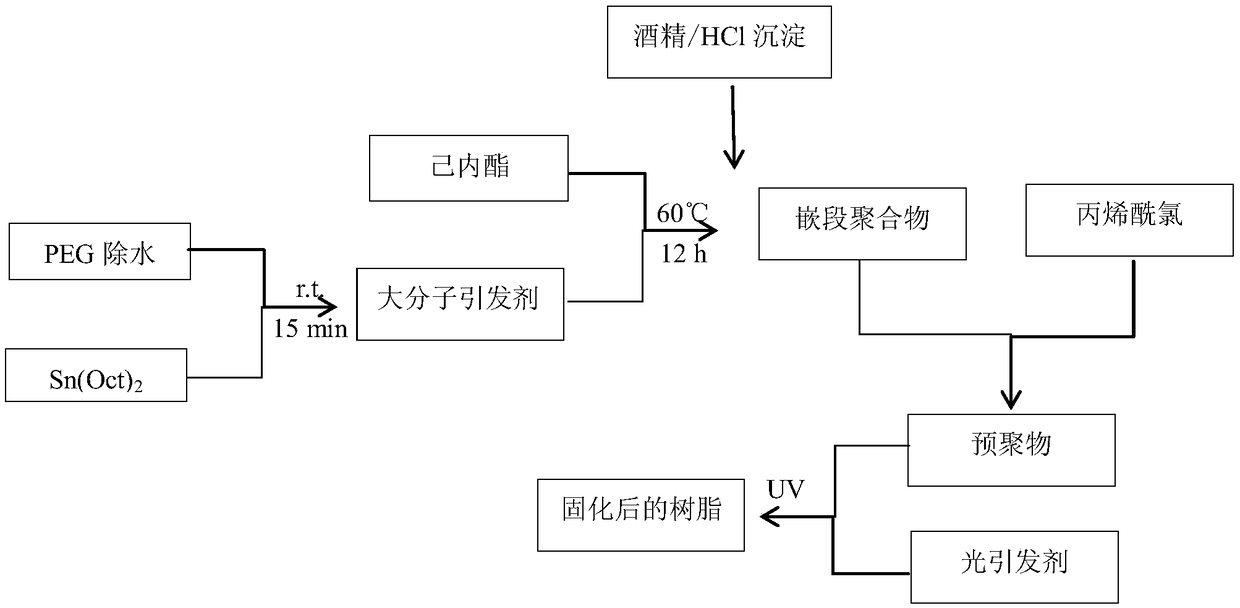

[0021] refer to Figure 1 ~ Figure 3 , a method for preparing a novel biodegradable fast photocuring material, the method comprising the following steps:

[0022] 1) The caprolactone after the dehydration of calcium hydride is subjected to a ring-opening reaction under the initiation of polyethylene glycol, and the polycaprolactone-polyethylene glycol-polycaprolactone block polymer PCEC is prepared;

[0023] 2) The product of step 1) is modified by acryloyl chloride to double bonds to prepare a block polymer enePCEC with double bond end groups;

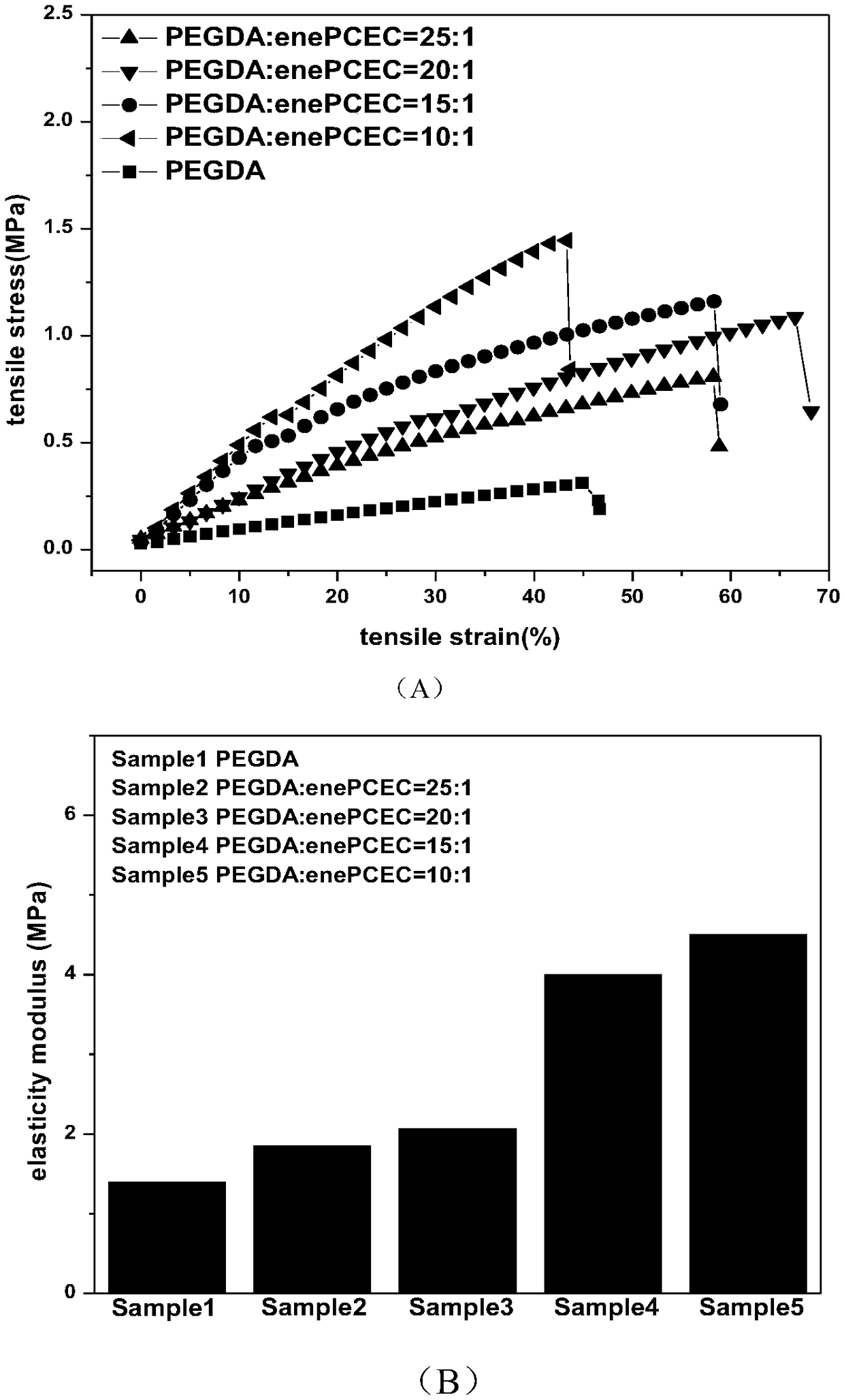

[0024] 3) The product in the step 2) obtained with chain extender (polyethylene glycol diacrylate PEGDA), crosslinking agent (tetrakis (3-mercaptopropionic acid) pentaerythritol ester), photoinitiator (benzoin dimethyl ether DMPA) is cured after UV irradiation.

[0025] Further, in the step 1), the preparation process of PCEC is as follows: before the experimental reaction, all reaction reagents and solvents are treated with calcium...

Embodiment 2

[0029] refer to Figure 1 ~ Figure 3 , a method for preparing a novel biodegradable fast photocuring material, the method comprising the following steps:

[0030] 1) The caprolactone after the dehydration of calcium hydride is subjected to a ring-opening reaction under the initiation of polyethylene glycol, and the polycaprolactone-polyethylene glycol-polycaprolactone block polymer PCEC is prepared;

[0031] 2) The product of step 1) is modified by acryloyl chloride to double bonds to prepare a block polymer enePCEC with double bond end groups;

[0032] 3) The product in the step 2) obtained with chain extender (polyethylene glycol diacrylate PEGDA), crosslinking agent (tetrakis (3-mercaptopropionic acid) pentaerythritol ester), photoinitiator (benzoin dimethyl ether DMPA) is cured after UV irradiation.

[0033] Further, in the step 1), the preparation process of PCEC is as follows: before the experimental reaction, all reaction reagents and solvents are treated with calcium...

Embodiment 3

[0037] refer to Figure 1 ~ Figure 3 , a method for preparing a novel biodegradable fast photocuring material, the method comprising the following steps:

[0038] 1) The caprolactone after the dehydration of calcium hydride is subjected to a ring-opening reaction under the initiation of polyethylene glycol, and the polycaprolactone-polyethylene glycol-polycaprolactone block polymer PCEC is prepared;

[0039] 2) The product of step 1) is modified by acryloyl chloride to double bonds to prepare a block polymer enePCEC with double bond end groups;

[0040] 3) The product in the step 2) obtained with chain extender (polyethylene glycol diacrylate PEGDA), crosslinking agent (tetrakis (3-mercaptopropionic acid) pentaerythritol ester), photoinitiator (benzoin dimethyl ether DMPA) is cured after UV irradiation.

[0041] Further, in the step 1), the preparation process of PCEC is as follows: before the experimental reaction, all reaction reagents and solvents are treated with calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com