Nanometer aluminum silicate composite powder-containing aqueous organic-inorganic hybrid anticorrosive coating and preparation method and using method thereof

A nano-aluminum silicate and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor water resistance, poor anti-rust and anti-corrosion performance, and weak adhesion, so as to reduce costs and improve performance. Stable and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

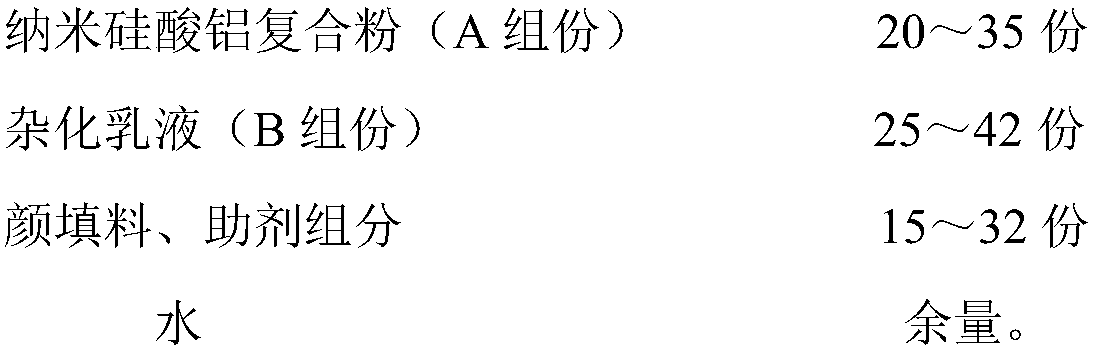

[0040] A kind of water-based organic-inorganic hybrid anticorrosion coating containing nano-aluminum silicate composite powder of the present embodiment, in 100 parts, said anticorrosion coating is made up of each component raw material of following parts by weight:

[0041]

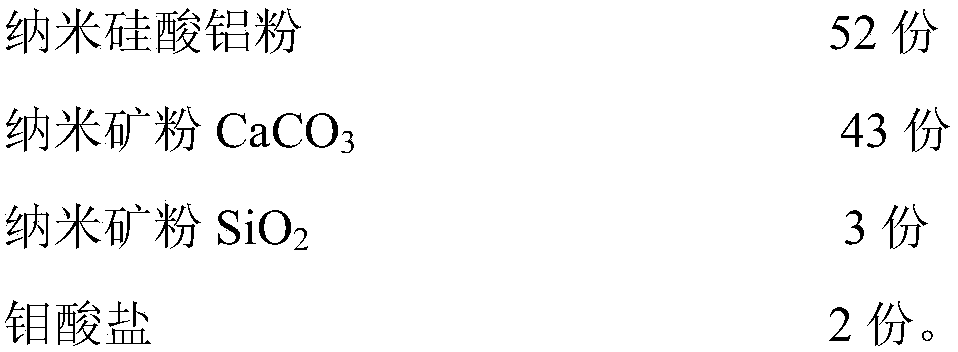

[0042] Wherein: the nano-aluminum silicate composite powder (component A) is formed by mixing the raw materials of the following components by weight: 52 parts of nano-aluminum silicate powder, nano-mineral powder CaCO 3 43 parts, nano mineral powder SiO 2 3 parts, molybdate 2 parts, mix well to get A component nano aluminum silicate composite powder.

[0043] The hybrid emulsion (component B) is formed by mixing the following components by weight: 82 parts of styrene-acrylic emulsion, 10 parts of silica sol, and 8 parts of triethanolamine; after mixing, the hybrid emulsion of component B is obtained .

[0044] The pigment and filler consist of 5 parts of talcum powder, 8 parts of superfine precip...

Embodiment 2

[0050] A kind of water-based organic-inorganic hybrid anticorrosion coating containing nano-aluminum silicate composite powder of the present embodiment, in 100 parts, said anticorrosion coating is made up of each component raw material of following parts by weight:

[0051]

[0052]

[0053] Wherein: the nano-aluminum silicate composite powder (component A) is formed by mixing the raw materials of the following components by weight: 52 parts of nano-aluminum silicate powder, nano-mineral powder CaCO 3 43 parts, nano mineral powder SiO 2 3 parts, molybdate 2 parts, mix well to get A component nano aluminum silicate composite powder.

[0054]The hybrid emulsion (component B) is prepared by mixing the following components by weight: 80 parts of acrylic emulsion, 10 parts of silica sol, and 10 parts of triethanolamine; after mixing, the hybrid emulsion of component B is obtained.

[0055] The pigment and filler consist of 5 parts of talcum powder, 8 parts of superfine pr...

Embodiment 3

[0061] A kind of water-based organic-inorganic hybrid anticorrosion coating containing nano-aluminum silicate composite powder of the present embodiment, in 100 parts, said anticorrosion coating is made up of each component raw material of following parts by weight:

[0062]

[0063] Wherein: the nano-aluminum silicate composite powder (component A) is formed by mixing the raw materials of the following components by weight: 52 parts of nano-aluminum silicate powder, nano-mineral powder CaCO 3 43 parts, nano mineral powder SiO 2 3 parts, molybdate 2 parts, mix well to get A component nano aluminum silicate composite powder.

[0064] The hybrid emulsion (component B) is formed by mixing the following components by weight: 82 parts of epoxy resin, 10 parts of silica sol, and 8 parts of triethanolamine; after mixing, the hybrid emulsion of component B is obtained .

[0065] The pigment and filler consist of 5 parts of talcum powder, 8 parts of superfine precipitated barium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com