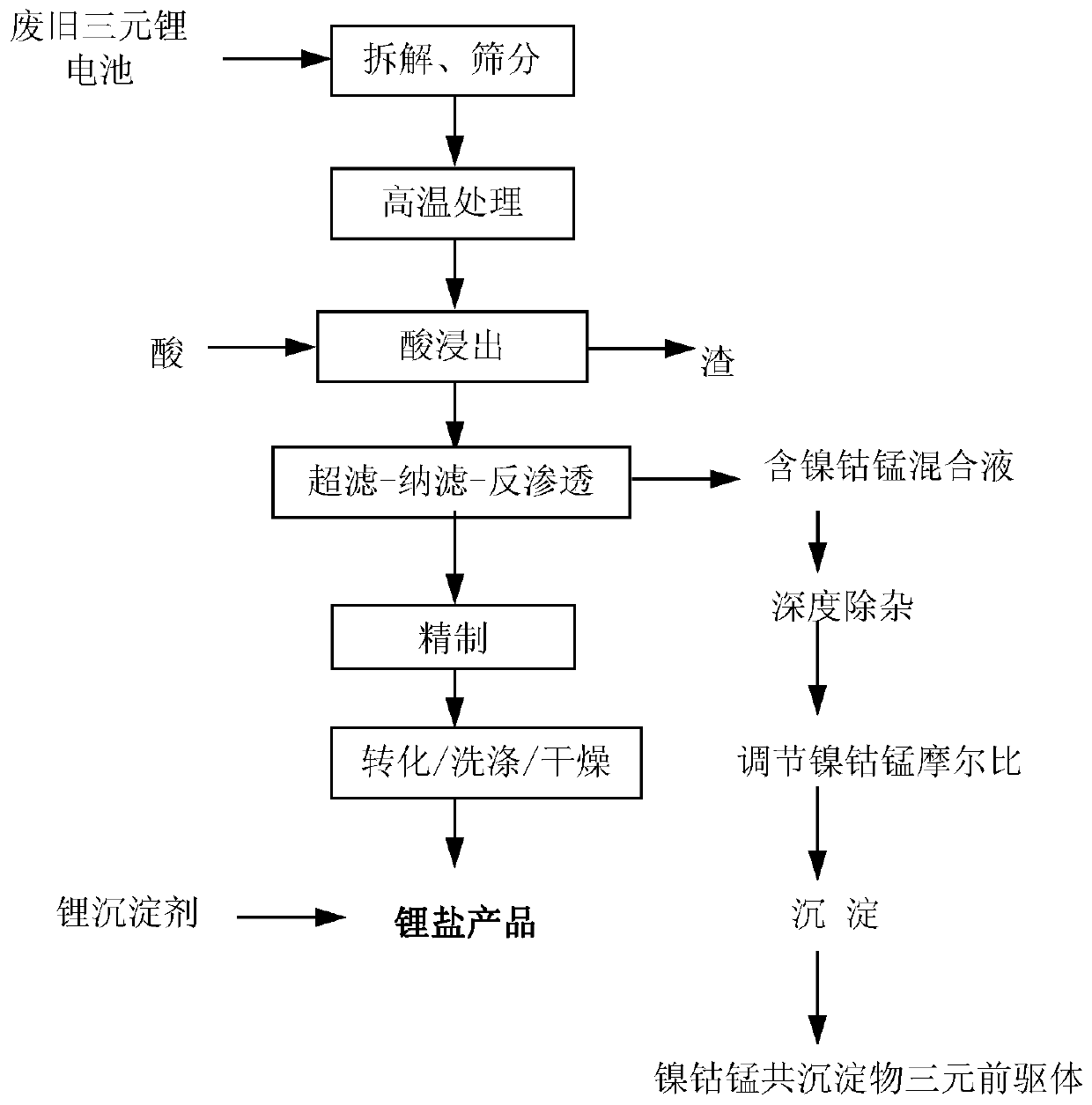

A method and system for comprehensively recovering valuable metals from waste ternary lithium batteries

A ternary lithium battery and valuable metal technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as bacterial culture, harsh use conditions, complex operation of ion exchange method, and restrictions on the application and promotion of technology , to achieve the effect of eliminating the use of organic extractants, high product purity, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

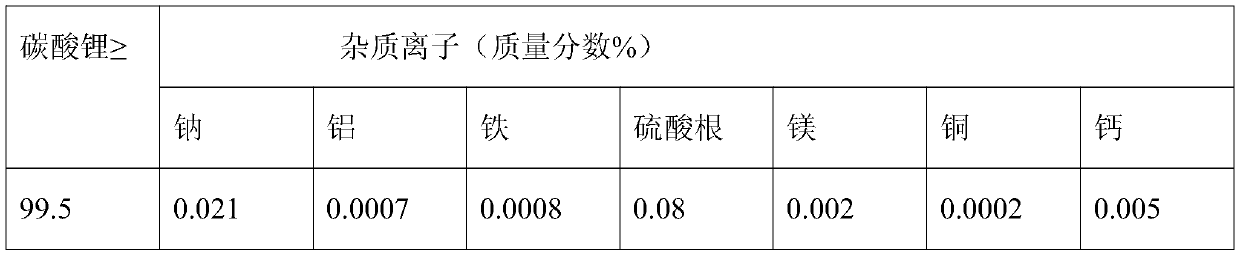

Embodiment 1

[0086] A certain type of waste ternary lithium battery is used as raw material. First, the waste batteries are discharged, disassembled and screened to obtain waste ternary cathode materials. Weigh 1 kg of waste ternary cathode material and treat it in a muffle furnace at 500 °C for 1 h, remove the binder, quench with water and treat in ultrasonic vibration for 30 min to peel off the cathode material and the aluminum foil. The large mesh screen is used to remove and separate the aluminum foil, and the aluminum foil can be directly used for aluminum smelting after washing. The obtained black fine slag was treated with 4 mol / L sulfuric acid, and 30% hydrogen peroxide was added at the same time, the solid-liquid ratio was controlled to 80 g / L, the temperature was controlled at 80 °C and continuously stirred for 4 hours, and then the leaching solution of valuable metals was obtained by filtration. The acid leaching residue is mainly acid-insoluble substances such as carbon powder...

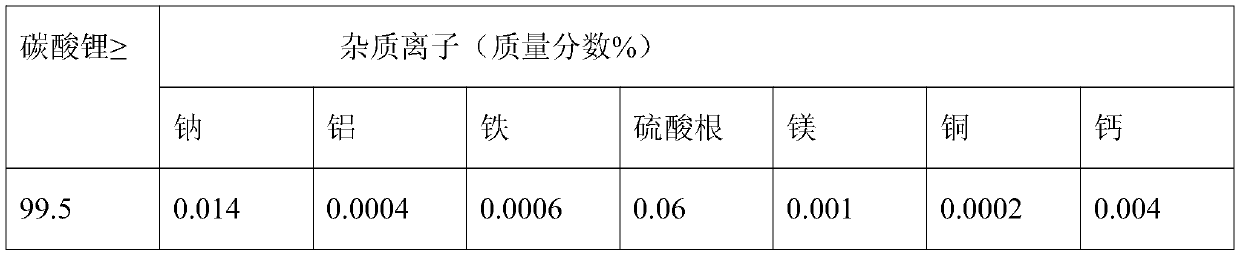

Embodiment 2

[0094] The ternary lithium cathode scrap of a certain enterprise is used as the raw material. Weigh 500 g of waste ternary positive electrode scraps and treat them in a muffle furnace at 450°C for 2 h, remove the binder, quench with water and treat in ultrasonic vibration for 60 min to peel off the positive electrode material and the aluminum foil. The large mesh screen is used to remove and separate the aluminum foil, and the aluminum foil can be directly used for aluminum smelting after washing. The obtained black fine slag was treated with 2 mol / L sulfuric acid, and 30% hydrogen peroxide was added at the same time, the solid-liquid ratio was controlled to 95 g / L, the temperature was controlled at 85 °C and continuously stirred for 3 hours, and then the leaching solution of valuable metals was obtained by filtration. The acid leaching residue is mainly acid-insoluble substances such as carbon powder. After testing the chemical composition in the leachate, the results are sh...

Embodiment 3

[0102] A certain type of waste ternary lithium battery is used as raw material. First, the waste batteries are discharged, disassembled and screened to obtain waste ternary cathode materials. Weigh 1.2 kg of waste ternary positive electrode material and treat it in a muffle furnace at 550°C for 2 hours, remove the binder, quench with water and treat in ultrasonic vibration for 45 minutes to peel off the positive electrode material and the aluminum foil. The large mesh screen is used to remove and separate the aluminum foil, and the aluminum foil can be directly used for aluminum smelting after washing. The obtained black finely crushed slag was treated with 3 mol / L hydrochloric acid, and 30% hydrogen peroxide was added at the same time, the solid-liquid ratio was controlled to 75 g / L, the temperature was controlled at 85 °C and continuously stirred for 6 h, and then the leaching solution of valuable metals was obtained by filtration. The acid leaching residue is mainly acid-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com