Anti-slip agent for tiles, and preparation method thereof

An anti-slip agent and ceramic tile technology, applied in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems of environmental impact, environmental pollution, poor anti-fouling effect of anti-slip tiles, etc., and achieve good weather resistance , strong chemical resistance, anti-slip effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An anti-slip agent for tiles, which is compounded by component A and component B according to the volume ratio of 1:0.8, and the component A includes the following raw materials in parts by weight:

[0048] Corrosion inhibitor 1%

[0049] Dispersion stabilizer 0.1%

[0050] Humectant 0.1%

[0051] The remainder is water;

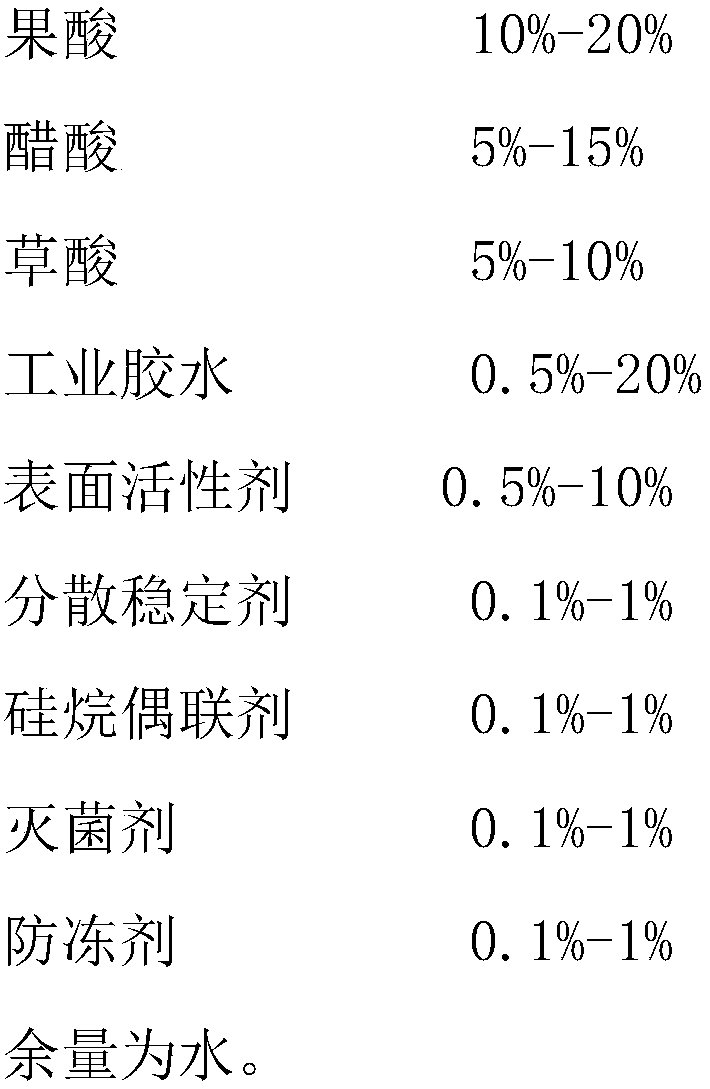

[0052] B component comprises the raw material of following weight portion:

[0053]

[0054] The corrosion inhibitor is compounded from salts of weak acids and strong bases and salts of weak bases and strong salts in a molar ratio of 1:0.8.

[0055] The dispersion stabilizer is ethylene glycol ether.

[0056] The sterilizing agent is dodecyl dimethyl benzyl ammonium chloride.

[0057] The antifreeze is nonylphenol polyoxyethylene ether.

[0058] The humectant is butanediol.

[0059] The silane coupling agent is sodium methyl silicate.

[0060] The surfactant is sodium dodecylbenzenesulfonate.

[0061] The preparation method of the ceramic ti...

Embodiment 2

[0070] An anti-slip agent for tiles, which is compounded by component A and component B according to the volume ratio of 1:2.5, and the component A includes the following raw materials in parts by weight:

[0071] Corrosion inhibitor 10%

[0072] Dispersion stabilizer 1%

[0073] Humectant 1%

[0074] The remainder is water;

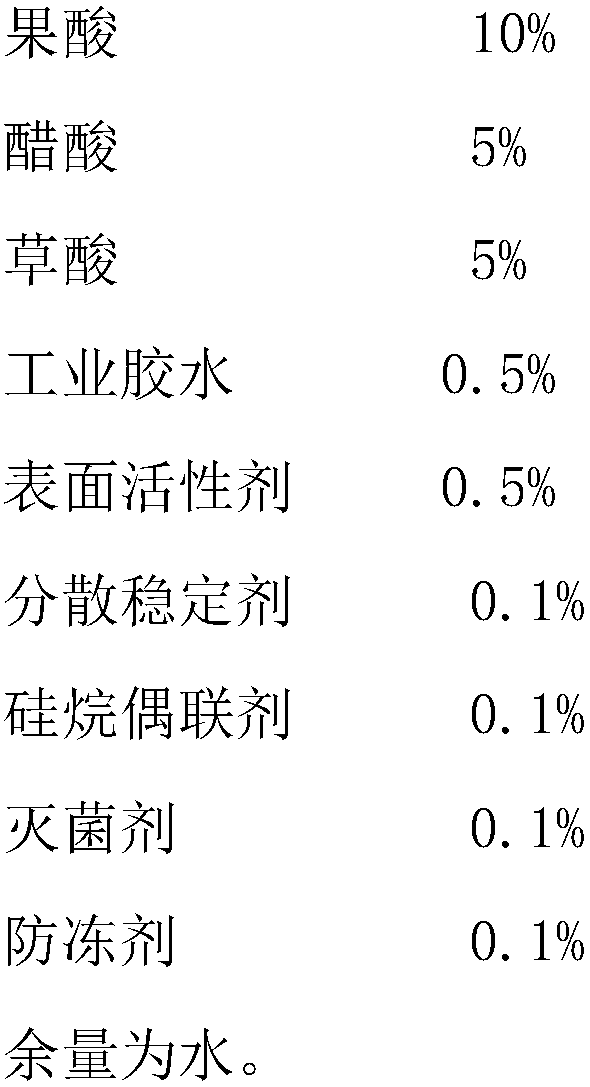

[0075] B component comprises the raw material of following weight portion:

[0076]

[0077]

[0078] The corrosion inhibitor is compounded by weak acid and strong base salt and weak base and strong salt according to the molar ratio of 1:1.2.

[0079] The dispersion stabilizer is ethylene glycol butyl ether.

[0080] The sterilant is ethanol.

[0081] The antifreeze is 1,2-propanediol.

[0082] Described humectant is propylene glycol.

[0083] The silane coupling agent is methyltrimethoxysilane.

[0084] The surfactant is sodium lauryl sulfate.

[0085] The preparation method of the ceramic tile anti-slip agent, the A component and the B c...

Embodiment 3

[0094] An anti-slip agent for ceramic tiles, which is compounded by component A and component B according to the volume ratio of 1:1, and the component A includes the following raw materials in parts by weight:

[0095] Corrosion inhibitor 5%

[0096] Dispersion stabilizer 0.2%

[0097] Humectant 0.3%

[0098] The remainder is water;

[0099] B component comprises the raw material of following weight portion:

[0100]

[0101] The corrosion inhibitor is compounded by weak acid and strong base salt and weak base and strong salt according to the molar ratio of 1:1.

[0102] The dispersion stabilizer is prepared by compounding ethylene glycol ethyl ether, nonylphenol polyoxyethylene ether and polyoxyethylene ether in a mass ratio of 1:0.8:0.2.

[0103] The sterilizing agent is a mixture of dodecyl dimethyl benzyl ammonium chloride and ethanol at a mass ratio of 1:0.3.

[0104] The antifreeze is made by compounding nonylphenol polyoxyethylene ether and 1,2-propylene glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com