Color polymer conductive bead and preparation method

A technology of polymer beads and polymers, which is applied in the field of colored polymer conductive beads and its preparation, can solve the problems of poor light fastness, reduced mechanical properties, poor compatibility with polymers, etc., and achieve good electrical conductivity and Effects of color, inhibition of secondary growth, and solvent recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Preparation of conductive polymer seed solution

[0048] Dissolve polyaniline in dimethyl sulfoxide to prepare 0.5 mg / mL polyaniline seed solution.

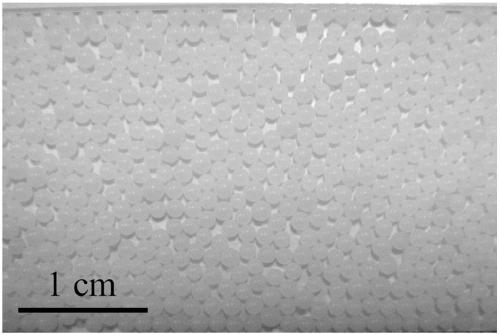

[0049] 2) Confinement and controllable swelling pretreatment of polymer beads

[0050] Weigh 15 g of polystyrene beads and disperse them in 25 mL of polystyrene beads in a mixed solvent of chloroform / ethanol (the volume ratio of chloroform and ethanol is 1:4), mechanically stir for 1 min, and the rotating speed is 40 rpm. Liquid separation to obtain pretreated polystyrene beads.

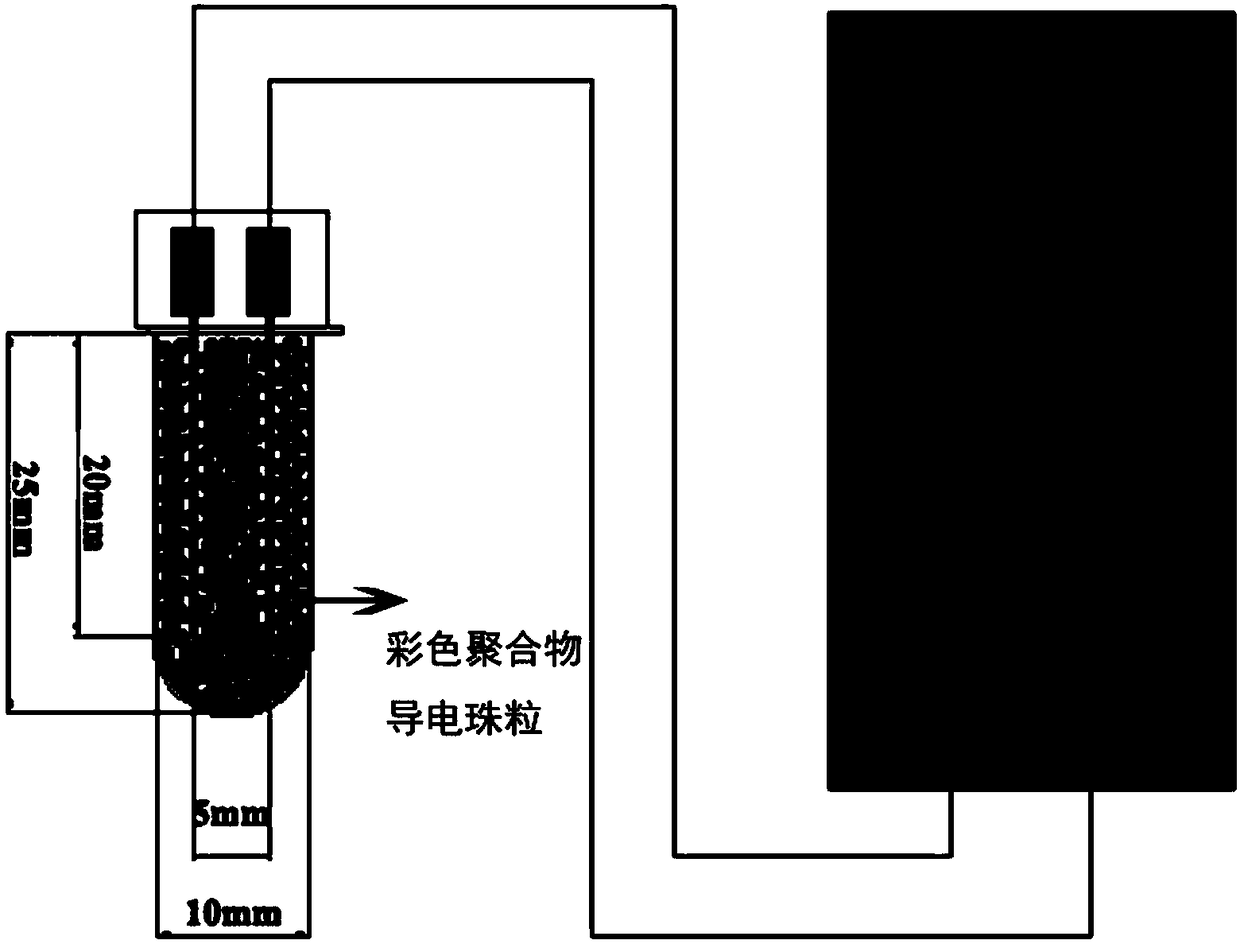

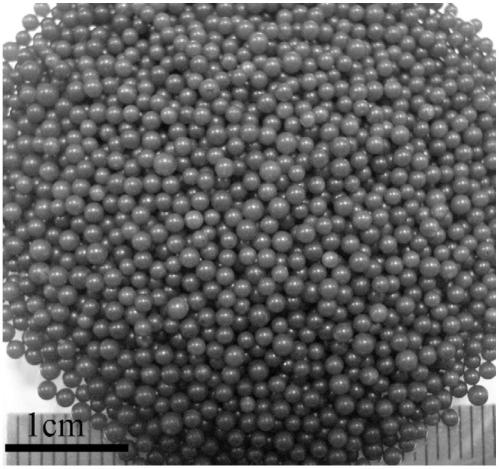

[0051] 3) Synthesis of colored polymer conductive beads

[0052] Add 20 mL of 0.5 mol / L aqueous hydrochloric acid solution, 3 mmol of aniline monomer and 0.5 mL of 0.5 mg / mL polyaniline seed solution into the reaction flask, then add 15 g of the pretreated polystyrene beads obtained in step 2) to the above system , keep the stirring speed at 60rpm, absorb for 6min, add dropwise an initiator solution consisting of 3mmol ammonium persulfate a...

Embodiment 2

[0054] 1) Preparation of conductive polymer seed solution

[0055] Dissolve polypyrrole in dimethyl sulfoxide to prepare 1 mg / mL polypyrrole seed solution.

[0056] 2) Confinement and controllable swelling pretreatment of polymer beads

[0057] Weigh 20 g of polymethyl methacrylate beads and disperse them in the mixed solvent of dichloromethane / methanol (the volume ratio of dichloromethane and methanol is 1:6) of 30 mL of polymethyl methacrylate beads, mechanically stir for 2 min , with a rotating speed of 50 rpm, and solid-liquid separation to obtain pretreated polymethyl methacrylate beads.

[0058] 3) Synthesis of colored polymer conductive beads

[0059] Add 25 mL of 0.8 mol / L phosphoric acid aqueous solution, 5 mmol of pyrrole monomer and 1 mL of 1 mg / mL polypyrrole seed solution to the reaction flask, then add 20 g of the pretreated polymethyl methacrylate beads obtained in step 2) to the above system In the process, keep the stirring speed at 80rpm, absorb for 12min,...

Embodiment 3

[0061] 1) Preparation of conductive polymer seed solution

[0062] Dissolve polyaniline in dimethyl sulfoxide to prepare 1.2 mg / mL polyaniline seed solution.

[0063] 2) Confinement and controllable swelling pretreatment of polymer beads

[0064] Weigh 25g of expandable polystyrene beads and disperse them in the mixed solvent of toluene / propanol of 40mL of polymer beads (the volume ratio of toluene to propanol is 1:8), mechanically stir for 4min, the rotating speed is 60rpm, solid Liquid separation to obtain pretreated expandable polystyrene beads.

[0065] 3) Synthesis of colored polymer conductive beads

[0066] Add 30mL of 1mol / L perchloric acid aqueous solution, 8mmol aniline monomer and 1mL of 1.2mg / mL polyaniline seed solution to the reaction bottle, then, add 25g of pretreated expandable polystyrene beads obtained in step 2) In the above system, keep the stirring speed at 90rpm, absorb for 15min, add dropwise the initiator solution composed of 8mmol ammonium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com