Concrete beautifying maintenance paint with carbonization resistance, corrosion resistance, and self-cleaning performance

A technology for concrete and coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of no anti-carbonization function, no anti-corrosion performance, poor adaptability to the environment, etc., and achieve excellent high and low temperature resistance. , The effect of fast drying and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

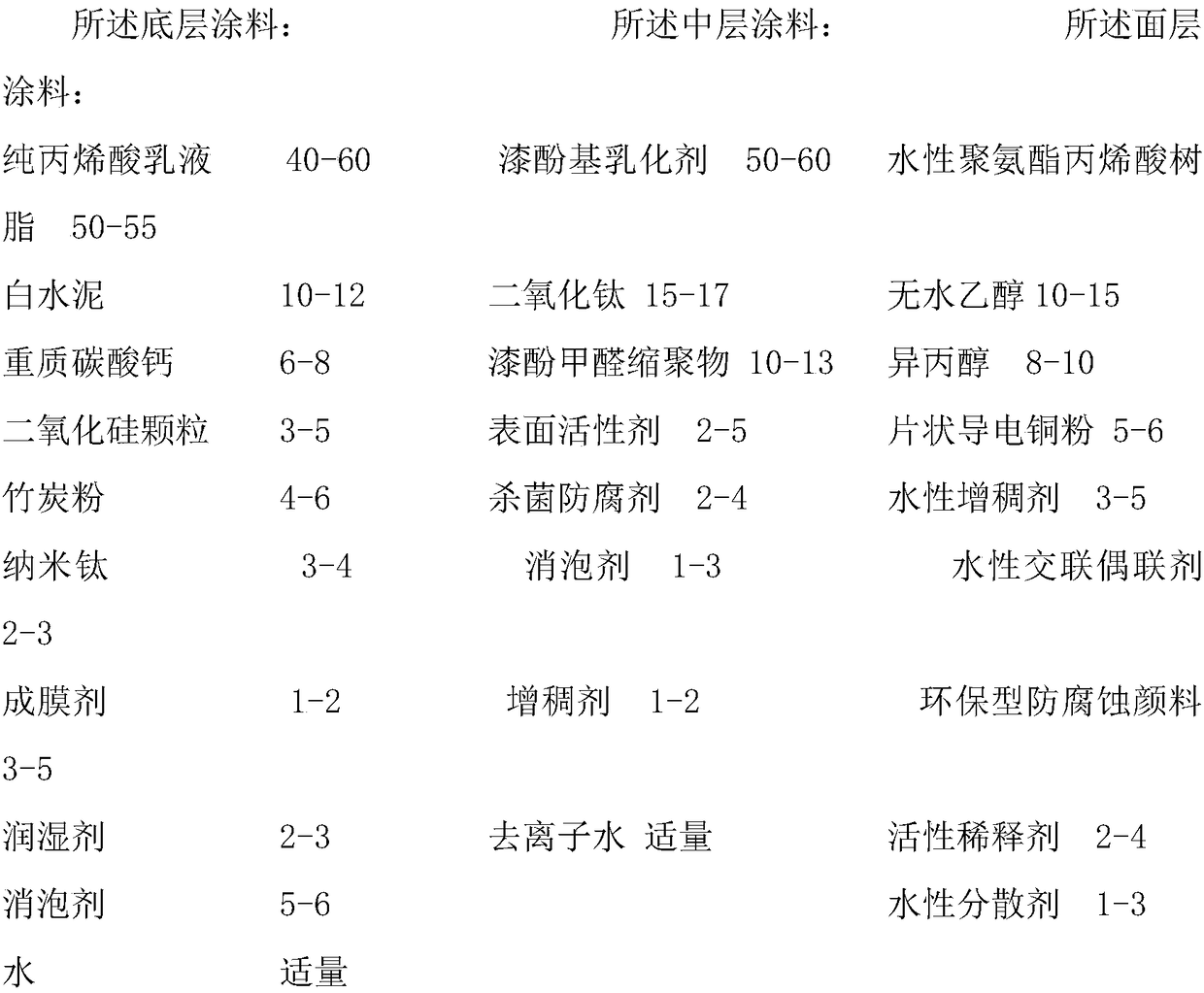

preparation example Construction

[0031] Preparation method of primer:

[0032] Step 1: Put the pure acrylic emulsion, white cement, heavy calcium carbonate, silicon dioxide particles, bamboo charcoal powder and nano-titanium into the double planetary stirring tank according to the measurement, stir for 2 hours and vacuumize;

[0033] Step 2: Stir and evacuate and cool for half an hour, then add metered film-forming agent, wetting agent, and defoamer in sequence, and stir for 1 hour;

[0034] Step 3: Vacuum stirring and cooling for 20 minutes, then transfer to a plastic drum for airtight packaging, and put it into A drum.

[0035] The preparation method of middle coating:

[0036] Step 1: put the urushiol-based emulsifier, titanium dioxide, urushiol-formaldehyde condensation polymer, and surfactant into the double planetary stirring tank according to the metering, stir for 1 hour and evacuate;

[0037] Step 2: Stir and evacuate and cool for 20 minutes, then add measured bactericidal preservatives, defoamers,...

Embodiment 1

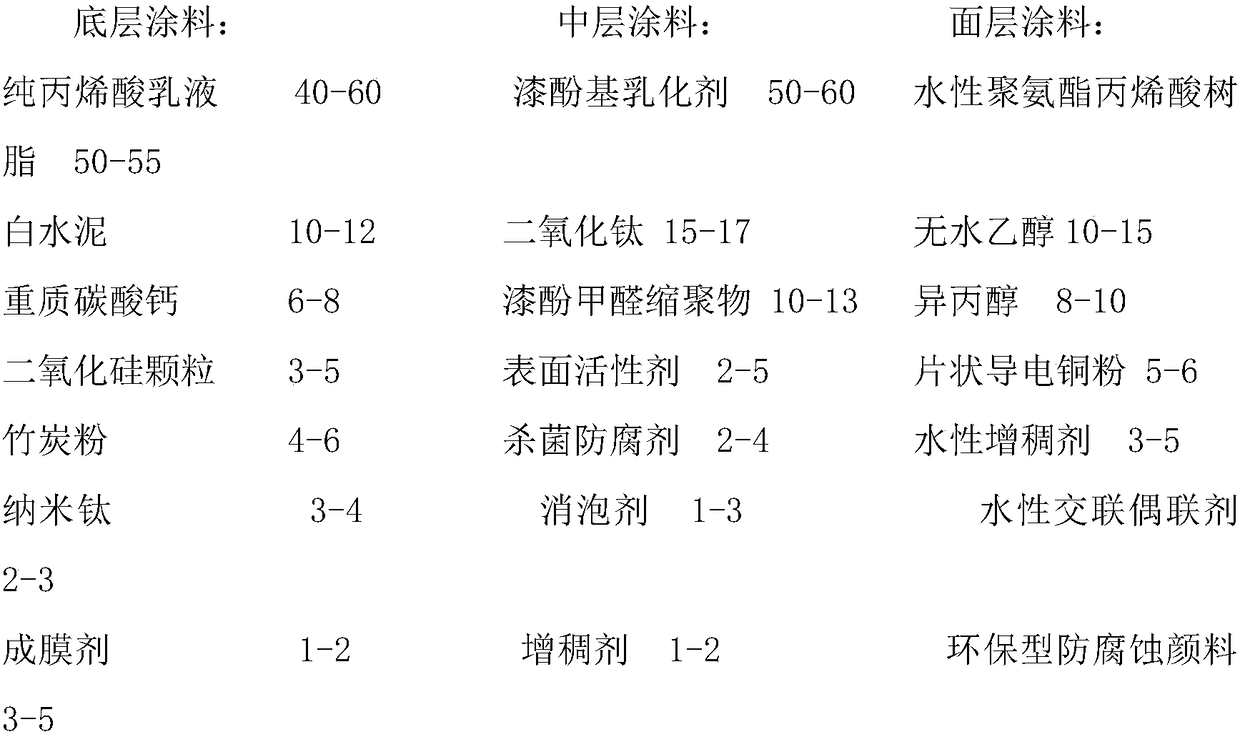

[0050] Recipe and its proportions:

[0051]

[0052] Preparation method of primer:

[0053] Step 1: Put the pure acrylic emulsion, white cement, heavy calcium carbonate, silicon dioxide particles, bamboo charcoal powder and nano-titanium into the double planetary stirring tank according to the measurement, stir for 2 hours and vacuumize;

[0054] Step 2: Stir and evacuate and cool for half an hour, then add metered film-forming agent, wetting agent, and defoamer in sequence, and stir for 1 hour;

[0055] Step 3: Vacuum stirring and cooling for 20 minutes, then transfer to a plastic drum for airtight packaging, and put it into A drum.

[0056] The preparation method of middle coating:

[0057] Step 1: put the urushiol-based emulsifier, titanium dioxide, urushiol-formaldehyde condensation polymer, and surfactant into the double planetary stirring tank according to the metering, stir for 1 hour and evacuate;

[0058] Step 2: Stir and evacuate and cool for 20 minutes, then a...

Embodiment 2

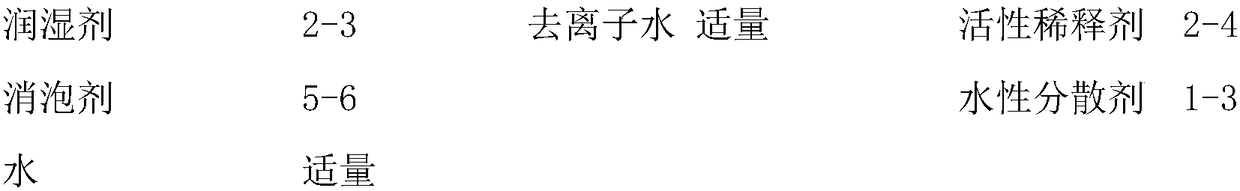

[0068] Recipe and its proportions:

[0069]

[0070] Preparation method of primer:

[0071] Step 1: Put the pure acrylic emulsion, white cement, heavy calcium carbonate, silicon dioxide particles, bamboo charcoal powder and nano-titanium into the double planetary stirring tank according to the measurement, stir for 2 hours and vacuumize;

[0072] Step 2: Stir and evacuate and cool for half an hour, then add metered film-forming agent, wetting agent, and defoamer in sequence, and stir for 1 hour;

[0073] Step 3: Vacuum stirring and cooling for 20 minutes, then transfer to a plastic drum for airtight packaging, and put it into A drum.

[0074] The preparation method of middle coating:

[0075] Step 1: put the urushiol-based emulsifier, titanium dioxide, urushiol-formaldehyde condensation polymer, and surfactant into the double planetary stirring tank according to the metering, stir for 1 hour and evacuate;

[0076] Step 2: Stir and evacuate and cool for 20 minutes, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com