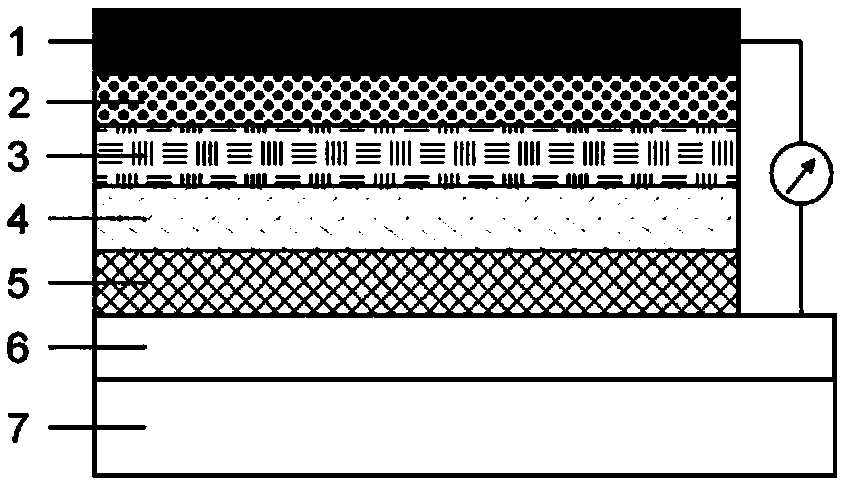

A hybrid solar cell based on the integration of multiple heterojunction properties and a preparation method thereof

A solar cell and heterojunction technology, applied in the field of hybrid solar cells and its preparation, can solve the problems of short diffusion length of polymer excitons and severe interfacial charge recombination, reduce the degree of interfacial charge recombination, and improve photogenerated current , to overcome the effect of short diffusion length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Etching and cleaning of ITO conductive glass:

[0042] First put the ITO conductive glass (size is 3×3cm 2 , ≤15Ω / □) with hydrochloric acid and Zn powder with a concentration of 6mol / L to etch the ITO layer into four strips of 16×4mm 2 The thin strips were ultrasonically cleaned with acetone, isopropanol, and ultrapure water for 5 minutes in sequence, and then dried with dry nitrogen to obtain etched ITO conductive glass deposition for later use.

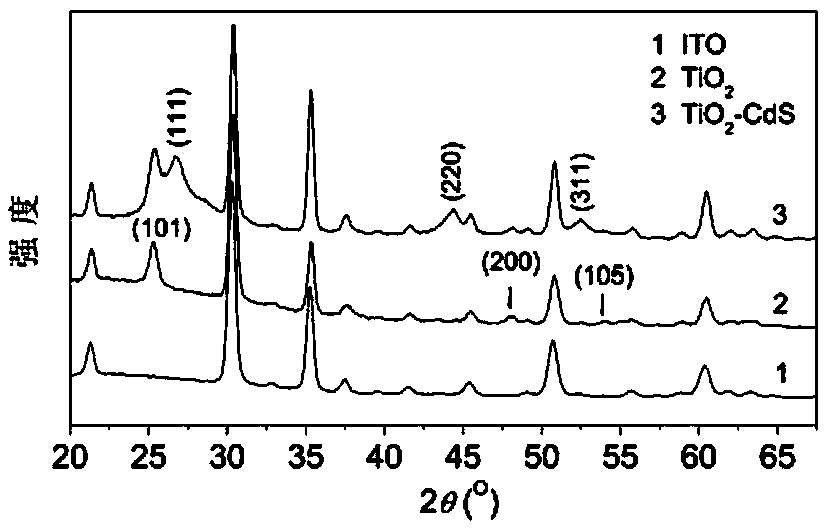

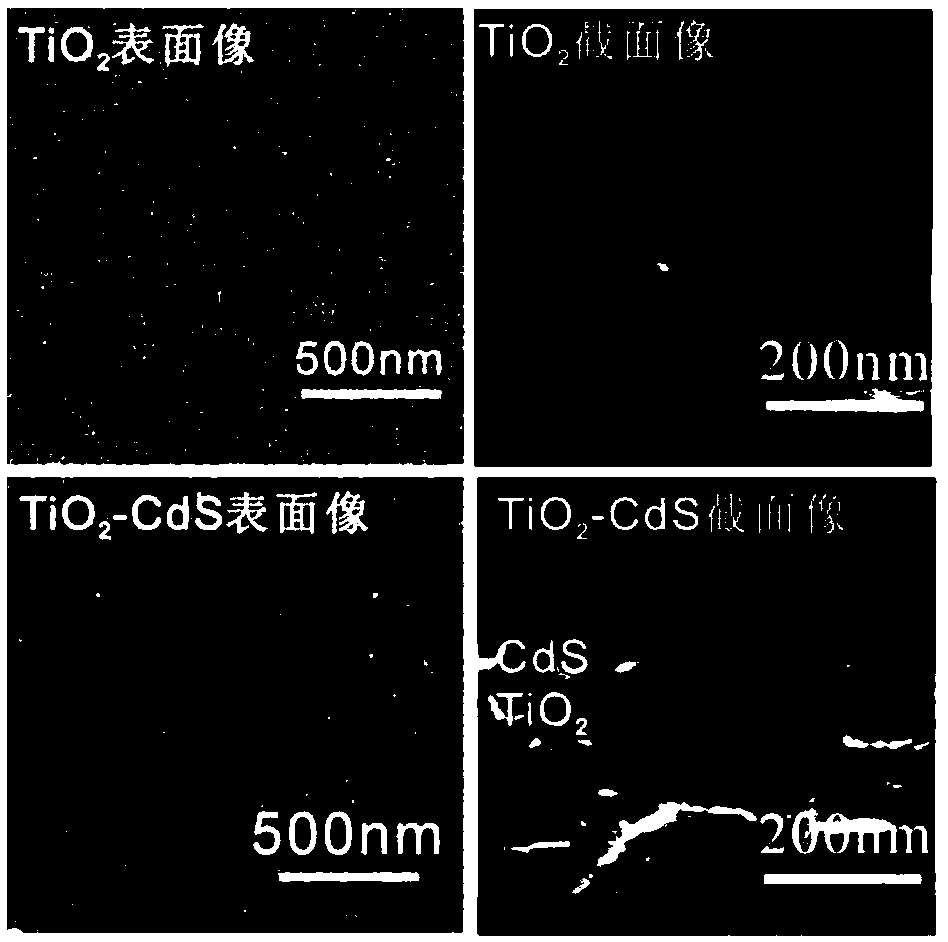

[0043] TiO 2 Preparation of nanostructured films:

[0044] Mix absolute ethanol, n-butyl titanate, and glacial acetic acid at a volume ratio of 4:1:0.1 to prepare uniform, colorless, and transparent TiO 2 Sol precursor. 150 μL of TiO 2 The sol precursor liquid is dropped on the etched ITO conductive glass, and spin-coated (2000 rpm, 30 seconds) to obtain TiO 2 Sol film; the TiO 2 After the sol film was stored at room temperature in a humidifier with a relative humidity of 50% for 12 hours, it was placed in an air-atmos...

Embodiment 2

[0052] Preparation of PTB7-th:ITIC blend films:

[0053] Using chlorobenzene as a solvent, prepare a solution of PTB7-th: ITIC with a total concentration of 10 mg / mL at a ratio of 1:1, and stir at 40°C for 12 hours to obtain a PTB7-th: ITIC blended chlorobenzene solution; Li PTB7-th:ITIC blend solution uniformly dispersed in TiO 2 - on the CdS heterojunction thin film layer, and then spin coating (1500 rpm, 60 seconds) to deposit the polymer onto the TiO 2 - On CdS heterojunction films; heat treatment at 100 °C for 10 min in a nitrogen-protected glove box to make the polymer and TiO 2 -CdS heterojunction film with sufficient contact.

[0054] In addition, the PTB7-th: ITIC blend film, PTB7-th film and ITIC film were prepared on the glass substrate with the same spin-coating method by the same method for testing their basic photophysical properties; , the concentration of the chlorobenzene solution of PTB7-th and ITIC used is also 10mg / mL.

[0055] TiO 2 -CdS / PTB7-th: Fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com