Preparation method of graphene gradient-coated polyacrylic acid composite conducting particles

A technology of polyacrylic acid and conductive particles, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of easy-off conductivity, non-wear resistance, poor bonding force of the surface coating layer, etc., and achieve dimensional stability Good, reduce the density, avoid the effect of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

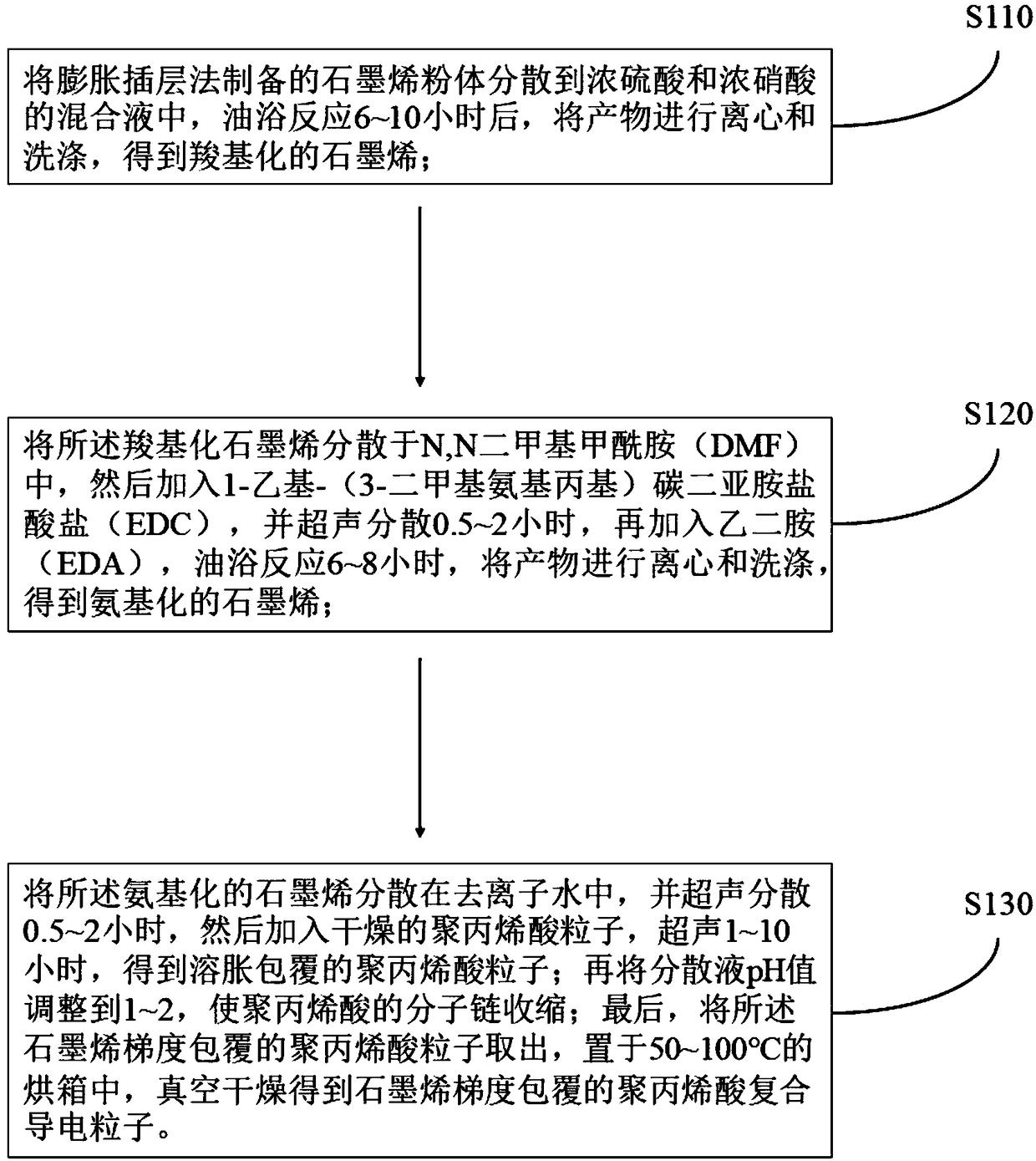

[0035] see figure 1 , the preparation method of the graphene gradient coating polyacrylic acid composite conductive particle of one embodiment, comprises the steps:

[0036] S110 disperses the graphene powder prepared by the expansion intercalation method into deionized water, then adds concentrated sulfuric acid and concentrated nitric acid, and reacts in an oil bath at 50°C for 6 to 10 hours, then centrifuges and washes the product to obtain carboxylated Graphene. Its main reaction equation is as follows:

[0037]

[0038]

[0039] Among them, the graphene powder prepared by the expansion intercalation method has an atomic percentage of oxygen less than 1%, and a sheet diameter between 100 nm and 10 μm. The concentration of the graphene powder prepared by the expansion intercalation method is 1.2-5 mg / ml. The mass concentration of concentrated sulfuric acid is 70%, the mass concentration of concentrated nitric acid is 70%, and the volume ratio of concentrated sulfur...

Embodiment 1

[0053] In the present embodiment, the preparation method of the polyacrylic acid composite conductive particles coated with graphene gradient is as follows:

[0054] 1. Weigh 150 mg of expanded intercalated graphene raw material, the atomic percentage of oxygen in the graphene powder is 0.5%, the sheet diameter is 3-5 μm, dissolve in the mixture of concentrated sulfuric acid and concentrated nitric acid, ultrasonic for 1 hour, concentrated The volume ratio of sulfuric acid and concentrated nitric acid is 3:1, and the volume of concentrated sulfuric acid and concentrated nitric acid is 40mL.

[0055] 2. Put the ultrasonic dispersion liquid in a three-necked flask, and reflux reaction under a constant temperature digital display magnetic stirrer, the reaction temperature is 90°C, and the reaction time is 7 hours.

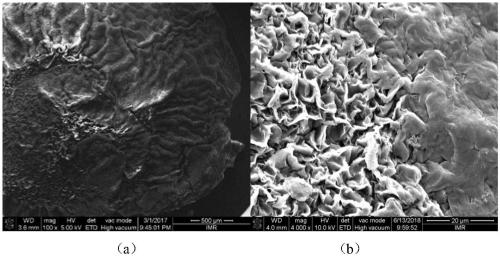

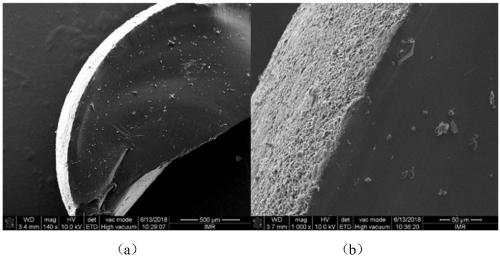

[0056] 3. Pour the reaction liquid into a large amount of deionized water to terminate the reaction. After standing for a period of time, pour off the supernatant liq...

Embodiment 2

[0066] In the present embodiment, the preparation method of the polyacrylic acid composite conductive particles coated with graphene gradient is as follows:

[0067] 1. Weigh 150 mg of expanded intercalated graphene raw material, the atomic percentage of oxygen in the graphene powder is 0.5%, the sheet diameter is 3-5 μm, dissolve in the mixture of concentrated sulfuric acid and concentrated nitric acid, ultrasonic for 1 hour, concentrated The volume ratio of sulfuric acid and concentrated nitric acid is 3:1, and the volume of concentrated sulfuric acid and concentrated nitric acid is 40mL.

[0068] 2. Put the ultrasonic dispersion liquid in a three-necked flask, and reflux reaction under a constant temperature digital display magnetic stirrer, the reaction temperature is 90°C, and the reaction time is 7 hours.

[0069] 3. Pour the reaction liquid into a large amount of deionized water to terminate the reaction. After standing for a period of time, pour off the supernatant liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com