Preparation method of graphene gradient-coated polyacrylic acid composite conductive particles

A polyacrylic acid, conductive particle technology, applied in the direction of dyeing polymer organic compounds, fibrous fillers, etc., can solve the problems of easy shedding conductivity, non-abrasion, poor adhesion of the surface coating layer, etc., and achieve dimensional stability. Good, reduce the density, avoid the effect of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

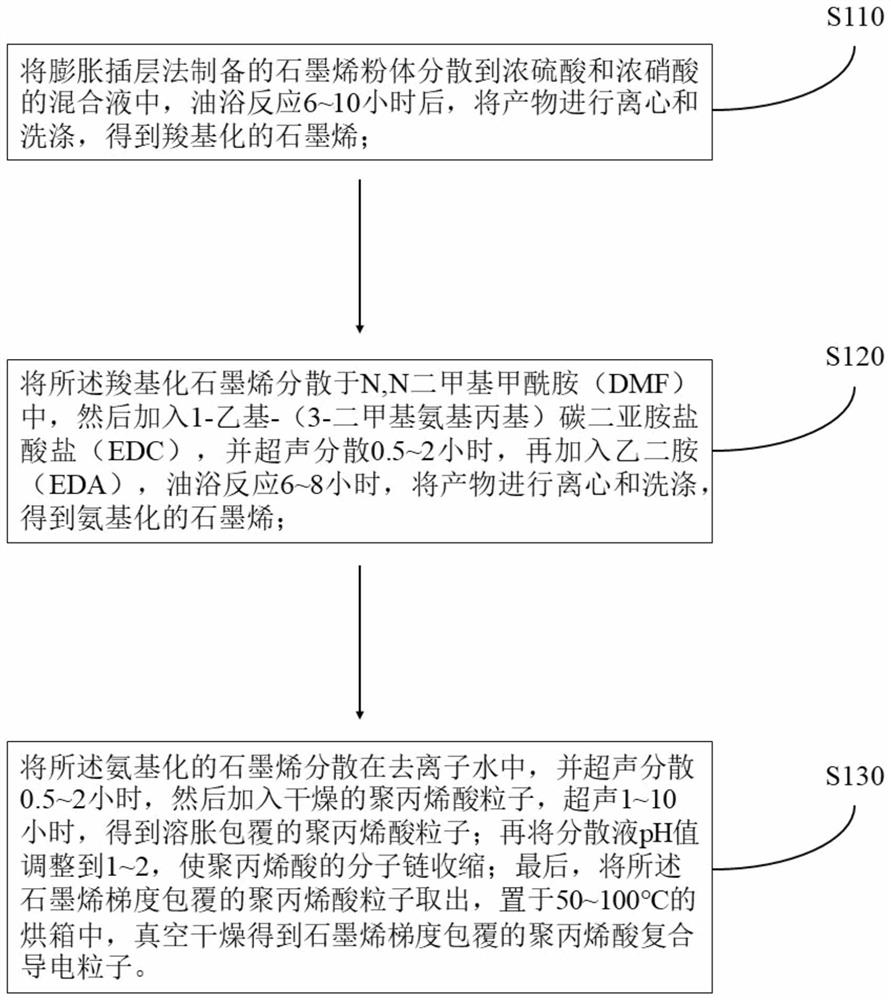

[0035] See figure 1 , The preparation method of the graphene gradient coated polyacrylic acid composite conductive particles, including the following steps:

[0036] S110 dispersed the graphene powder prepared by the expanded insertion layer to the deionized water, then concentrated sulfuric acid and concentrated nitric acid were added, and after 6 to 10 hours of 50 ° C, the product was centrifuged and washed, resulting in carboxylated Graphene. Its main reaction equation is as follows:

[0037]

[0038]

[0039] Among them, the graphene powder prepared by the expanded cladding method is less than 1%, and the diameter of the sheet is between 100 nm to 10 μm. The concentration of the graphene powder prepared from the expanded hindered method was 1.2 to 5 mg / ml. The high quality concentration of concentrated sulfuric acid was 70%, and the mass concentration of concentrated nitric acid was 70%, the volume ratio of concentrated sulfuric acid and concentrated nitric acid was 3: ...

Embodiment 1

[0053] In the present embodiment, the preparation method of the polyacrylic acid composite conductive particles coated in graphene gradient is as follows:

[0054] 1. Weighing the expansion inserted graphene raw material 150mg, the percentage of the oxygen in the graphene powder is 0.5%, the diameter of the sheet is 3 to 5 μm, soluble in concentrated sulfuric acid and concentrated nitric acid, ultrasonic 1 hour, concentrate The volume ratio of sulfuric acid and concentrated nitric acid is 3: 1, and the volume of concentrated sulfuric acid and concentrated nitric acid is 40 ml.

[0055] 2. Place the ultrasonic dispersion in a three-neck flask, reflux reaction at a thermostatic magnetic stirrer, and the reaction temperature is 90 ° C, and the reaction time is 7 hours.

[0056] 3. Pour the reaction liquid into a large amount of deionized water to terminate the reaction, and then press the upper liquid, and the remaining mixed liquid is separated by vacuum filtration, and the filter f...

Embodiment 2

[0066] In the present embodiment, the preparation method of the polyacrylic acid composite conductive particles coated in graphene gradient is as follows:

[0067] 1. Weighing the expansion inserted graphene raw material 150mg, the percentage of the oxygen in the graphene powder is 0.5%, the diameter of the sheet is 3 to 5 μm, soluble in concentrated sulfuric acid and concentrated nitric acid, ultrasonic 1 hour, concentrate The volume ratio of sulfuric acid and concentrated nitric acid is 3: 1, and the volume of concentrated sulfuric acid and concentrated nitric acid is 40 ml.

[0068] 2. Place the ultrasonic dispersion in a three-neck flask, reflux reaction at a thermostatic magnetic stirrer, and the reaction temperature is 90 ° C, and the reaction time is 7 hours.

[0069] 3. Pour the reaction liquid into a large amount of deionized water to terminate the reaction, and then press the upper liquid, and the remaining mixed liquid is separated by vacuum filtration, and the filter f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com