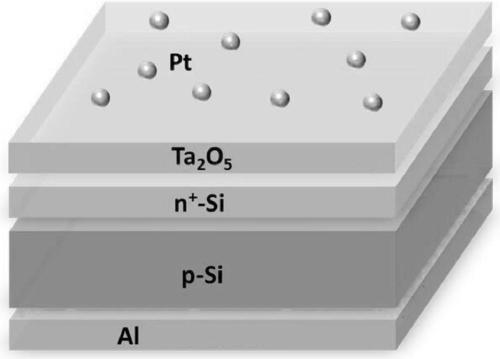

Tantalum oxide protected P-type silicon photocatalytic hydrogen evolution electrode and preparation method thereof

A technology of tantalum oxide and tantalum pentoxide, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of insufficient photogenerated voltage, instability, and heavy doping of single crystal silicon photocathode, and achieve the improvement of photolysis water production Hydrogen activity, enhanced stability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

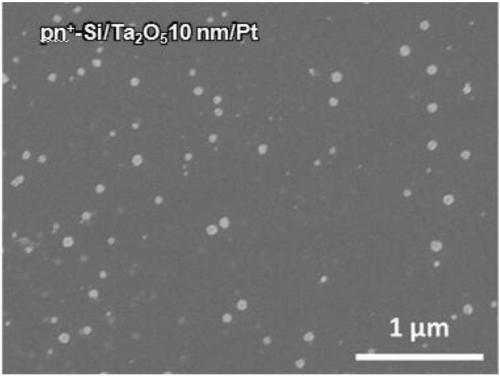

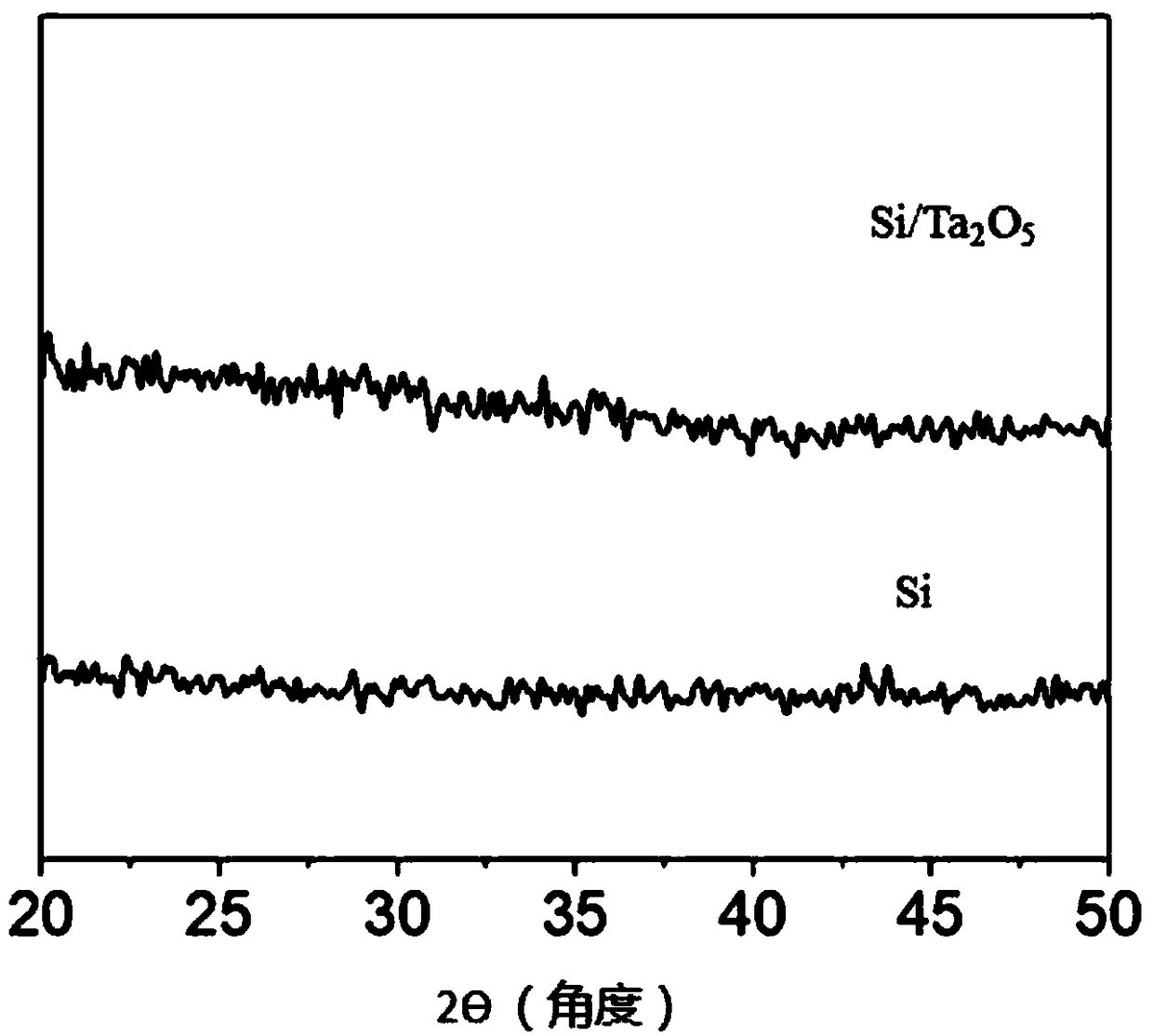

Examples

Embodiment 1

[0056] (1) The surface of the silicon wafer is heavily doped

[0057] a) After the silicon wafer is processed by RCA cleaning technology, it is blown dry with nitrogen gas for later use;

[0058] b) Preparation of silica latex: Take 15mL tetraethyl orthosilicate and mix with 33mL ethanol, heat to 60°C, and slowly add 2mL of 0.064% hydrochloric acid while stirring. The solution is heated to 70°C, stirred continuously, and kept warm for 2 hours to obtain the dopant solvent latex. After the preparation is completed, put it in the refrigerator at 0-5°C, and seal it for later use;

[0059] c) Phosphorus-containing dopant preparation: Take 0.0934g of phosphorus pentoxide, dissolve it in 2.5mL of silica latex, mix it evenly by ultrasonic, the dopant concentration is 0.0374mg / L, seal it for later use;

[0060] d) Spin-coating doping: Take 400 μL of phosphorus-containing dopant, set the spin-coater speed at about 3500 rpm, and spin-coating time for 30s. After the color of the film on ...

Embodiment 2

[0068] (1) The surface of the silicon wafer is heavily doped

[0069] a) After the silicon wafer is processed by RCA cleaning technology, it is blown dry with nitrogen gas for later use;

[0070] b) The preparation of silica latex is the same as in Example 1.

[0071] c) Phosphorus-containing dopant preparation: take 0.0934g of phosphorus pentoxide, dissolve in 5mL of silica latex, mix evenly by ultrasonic, the dopant concentration is 0.0187mg / L, and seal it for later use;

[0072] d) Spin-coating doping is the same as that in Example 1.

[0073] e) High-temperature roasting is the same as in Example 1.

[0074] (2) The preparation of the protective layer is the same as in Example 1.

[0075] (3) The deposition of platinum auxiliary agent is the same as that in Example 1.

Embodiment 3

[0077] (1) The surface of the silicon wafer is heavily doped

[0078] a) After the silicon wafer is processed by RCA cleaning technology, it is blown dry with nitrogen gas for later use;

[0079] b) The preparation of silica latex is the same as in Example 1.

[0080] c) Phosphorus-containing dopant preparation: take 0.1868g of phosphorus pentoxide, dissolve it in 2.5mL of silicon oxide latex, mix it uniformly by ultrasonic, the dopant concentration is 0.0747mg / L, and seal it for later use;

[0081] d) Spin-coating doping is the same as that in Example 1.

[0082] e) High-temperature roasting is the same as in Example 1.

[0083] (2) The preparation of the protective layer is the same as in Example 1.

[0084] (3) The deposition of platinum auxiliary agent is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com