System and method for evaluating emissions from equipment data

A technology of equipment data and emissions, applied in data processing applications, instruments, calculations, etc., can solve the problems of troublesome overall process and cumbersome detection process, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

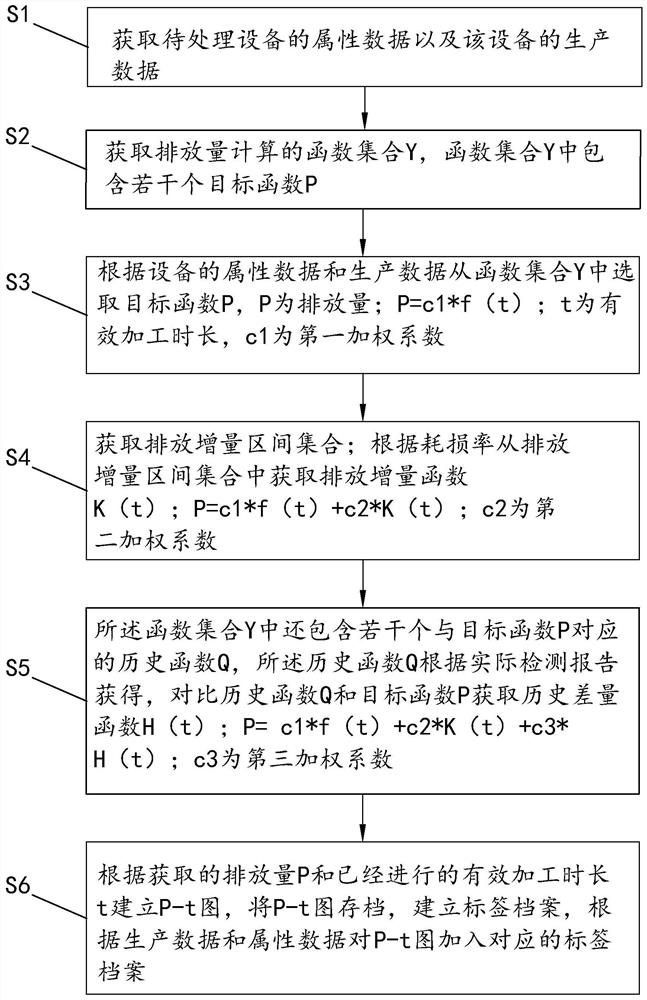

[0039] Example 1: A method for evaluating emissions according to equipment data, the method is applied to different equipment, and the emissions of equipment are evaluated and calculated, which mainly include the evaluation of waste gas, waste liquid, and waste solids. The equipment covered mainly includes reaction equipment, chemical furnaces, filtration equipment, drying equipment, mechanical pumps, crushing machinery, lifting equipment and transportation equipment in the chemical industry; cotton textile equipment, cotton printing and dyeing equipment, chemical fiber equipment, knitting equipment in the textile industry Equipment and textile instruments, wool, silk, knitting, yarn dyeing and finishing equipment, etc.; blast furnaces, steelmaking furnaces, coke ovens, rolling and forging equipment, sintering machines and power equipment in the metallurgical industry. Attribute data of each equipment includes model, equipment power, and / or operating voltage, and / or wear rate, ...

Embodiment 2

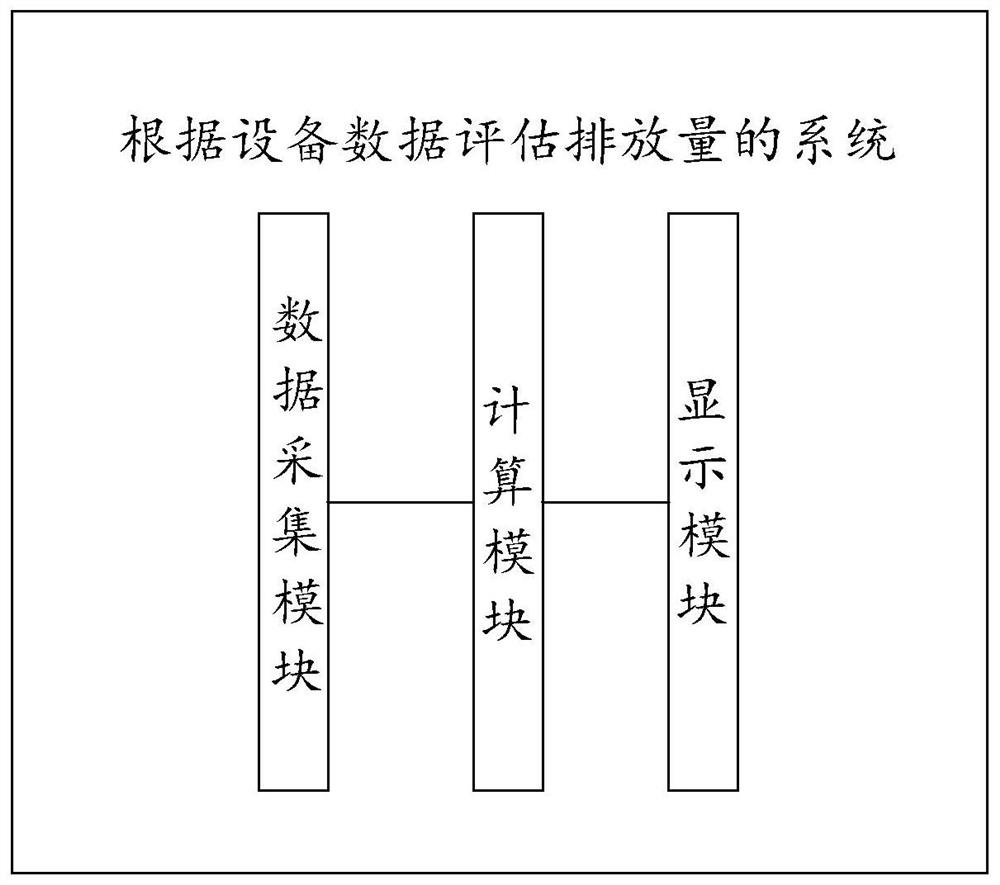

[0047] Example 2: as figure 2 , a system for evaluating emissions according to equipment data, including a data acquisition module, a calculation module and a display module, the data acquisition module collects the attribute data of the equipment to be processed and the production data of the equipment and sends it to the calculation module, the calculation module application embodiment 1. The method of evaluating the emission of equipment data is calculated, and the calculation module outputs the calculation result to the display module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com