A strong and sealed buried anti-corrosion insulation pipe and its preparation method

A heat preservation pipe and sealing technology, which is applied in the direction of heat preservation, anti-corrosion coating, and pipe protection through heat insulation, etc. It can solve the problems of incomplete matching of seams, troublesome maintenance of heat preservation pipes, troublesome disassembly of heat preservation pipes, etc., and achieves remarkable heat preservation effect , good thermal insulation effect, and enhanced thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

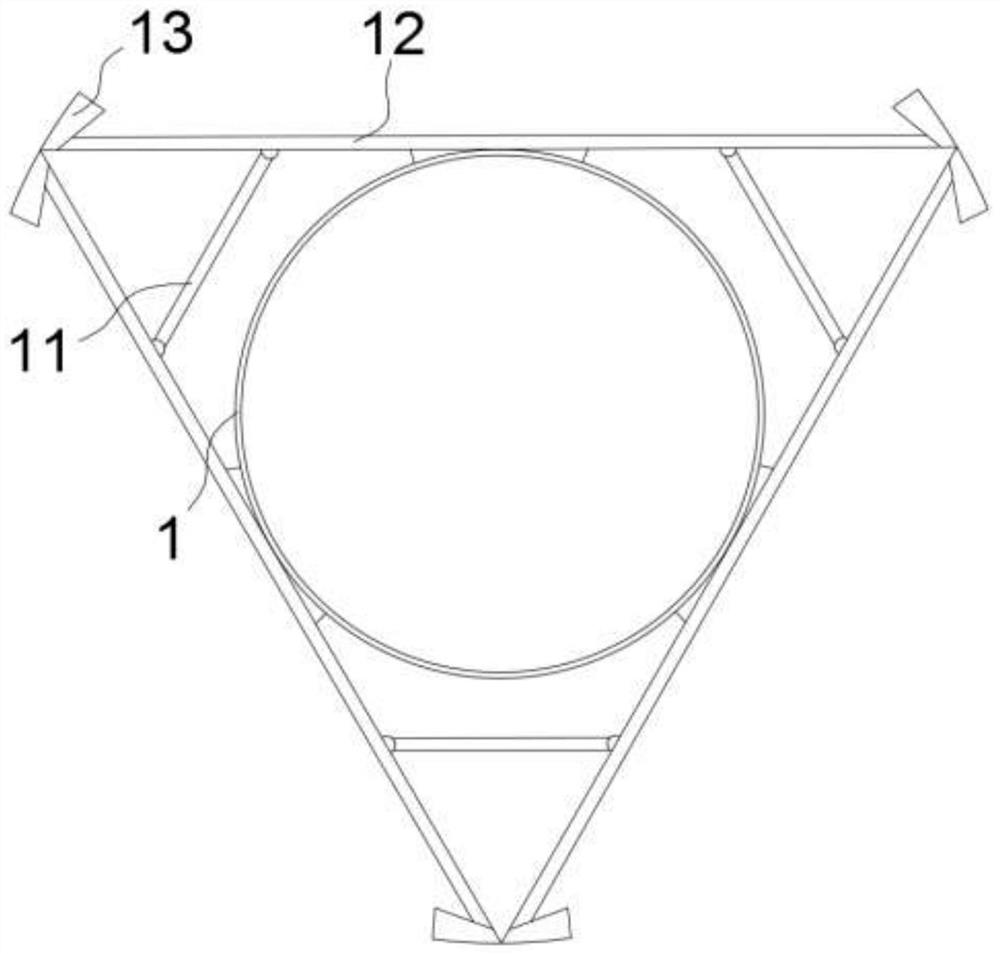

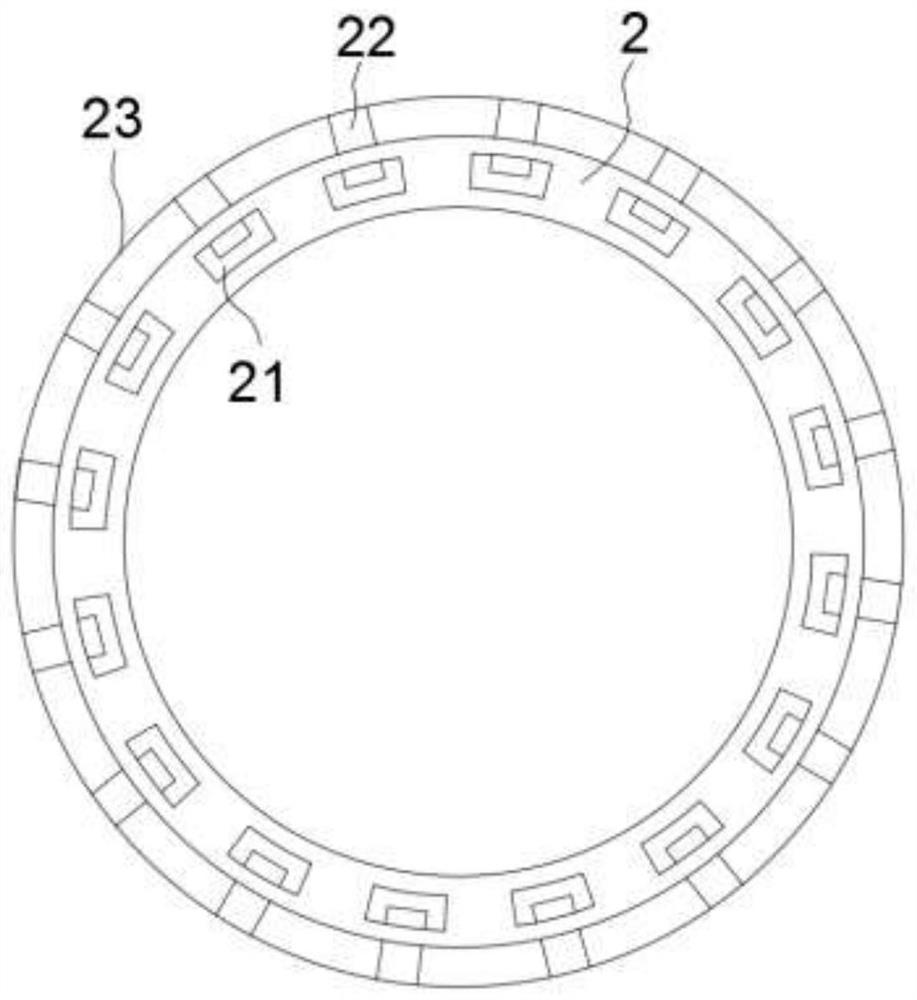

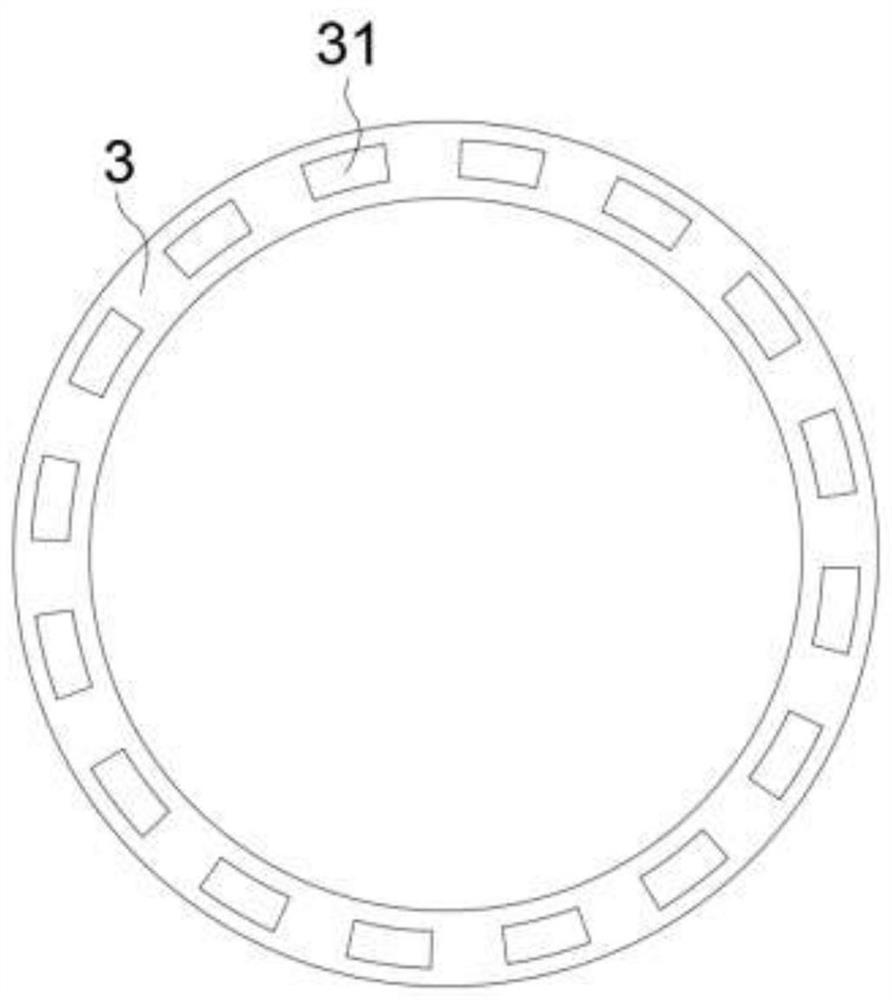

[0036] A strong and sealed buried anti-corrosion and thermal insulation pipe mainly includes a working pipe, an insulating layer and an outer protective pipe, and the working pipe, the insulating layer and the outer protective pipe are sequentially arranged from the inside to the outside;

[0037] The working pipe is a steel pipe, and its outer surface is coated with preservatives. The preservatives mainly include: cyanide, synergist and water; the mass ratio of cyanide, synergist and water is 1:10:25; the synergist includes Ingredients in the following percentages by weight: 4-toluenesulfonyl chloride 3%, sodium ethylenediamine tetramethylene phosphate 5%, carbon powder 0.5%, trichloroethyl phosphate 1%, trichlorofluoromethane 2%, solvent 50% , the balance is water; the solvent is acetone and ethanol mixed according to the volume ratio of 3:4; 4-toluenesulfonyl chloride and sodium ethylenediamine tetramethylene phosphate have strong thermal stability and corrosion resistance i...

Embodiment 2

[0049] A strong and sealed buried anti-corrosion and thermal insulation pipe mainly includes a working pipe, an insulating layer and an outer protective pipe, and the working pipe, the insulating layer and the outer protective pipe are sequentially arranged from the inside to the outside;

[0050] The working pipe is a steel pipe, and its outer surface is coated with preservatives. The preservatives mainly include: cyanide, synergist and water; the mass ratio of cyanide, synergist and water is 1.5:10:55; the synergist includes The following components by weight percentage: 4-toluenesulfonyl chloride 4%, sodium ethylenediamine tetramethylene phosphate 6%, carbon powder 0.7%, trichloroethyl phosphate 1.6%, trichlorofluoromethane 3.2%, solvent 60% , the balance is water; the solvent is acetone and ethanol mixed according to the volume ratio of 3:4; 4-toluenesulfonyl chloride and sodium ethylenediamine tetramethylene phosphate have strong thermal stability and corrosion resistance ...

Embodiment 3

[0062] A strong and sealed buried anti-corrosion and thermal insulation pipe mainly includes a working pipe, an insulating layer and an outer protective pipe, and the working pipe, the insulating layer and the outer protective pipe are sequentially arranged from the inside to the outside;

[0063] The working pipe is a steel pipe, and its outer surface is coated with preservatives. The preservatives mainly include: cyanide, synergist and water; the mass ratio of cyanide, synergist and water is 2:10:70; the synergist includes The following components by weight percentage: 4-toluenesulfonyl chloride 5%, sodium ethylenediamine tetramethylene phosphate 8%, carbon powder 1%, trichloroethyl phosphate 2%, trichlorofluoromethane 4%, solvent 65% , the balance is water; the solvent is acetone and ethanol mixed according to the volume ratio of 3:4; 4-toluenesulfonyl chloride and sodium ethylenediamine tetramethylene phosphate have strong thermal stability and corrosion resistance in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com