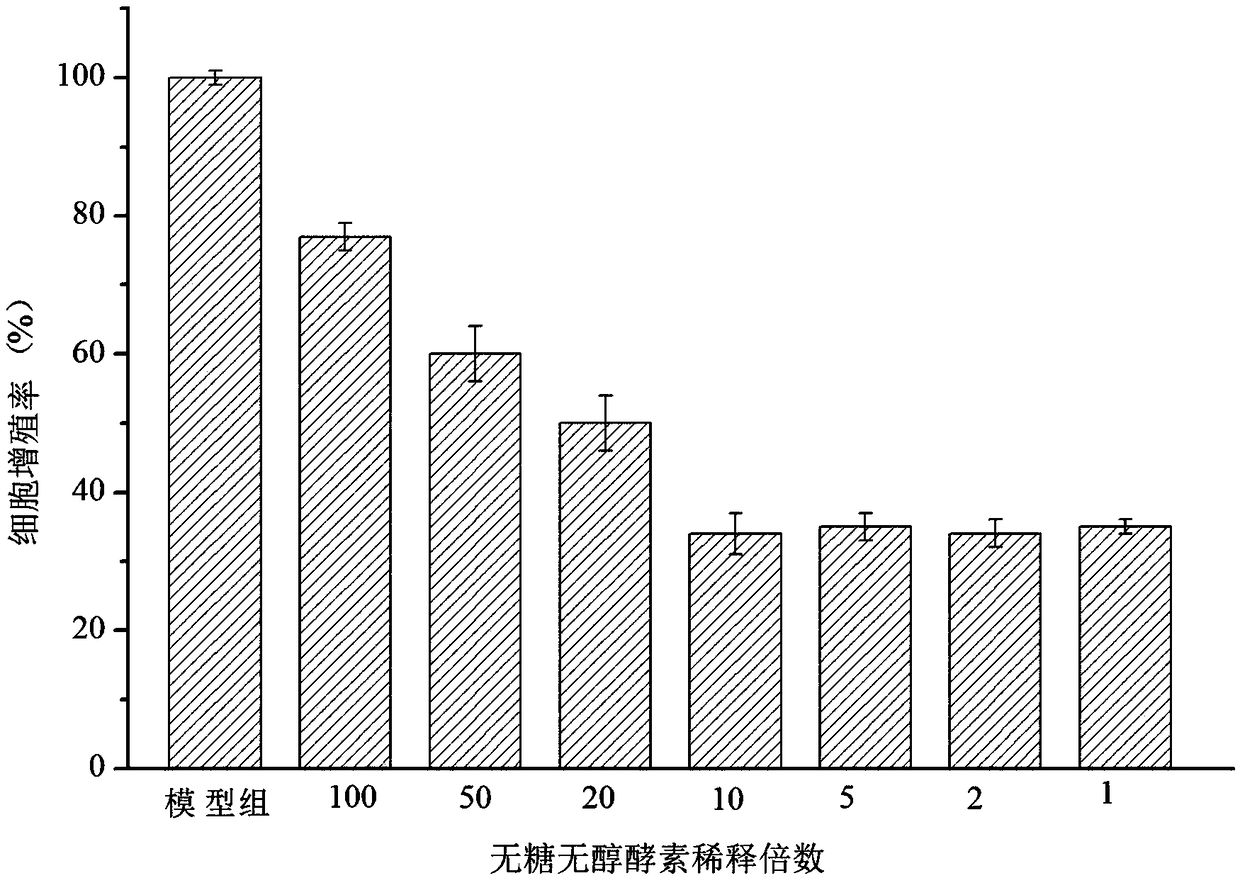

Preparation method of sugarless alcohol-free healthy composite enzyme beverage

A compound enzyme, alcohol-type technology, applied in the functions of food ingredients, food ingredients, food science and other directions, can solve the problems of easily destroying active nutrients, cumbersome operation, unfavorable health, etc., to expand the number of users and application fields, improve Absorption rate, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

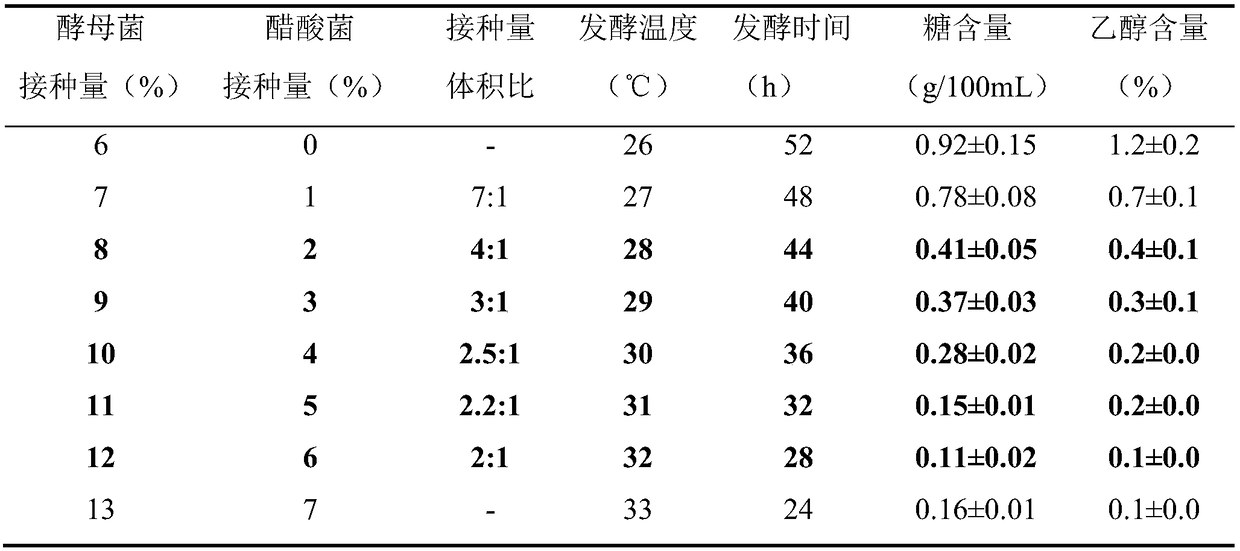

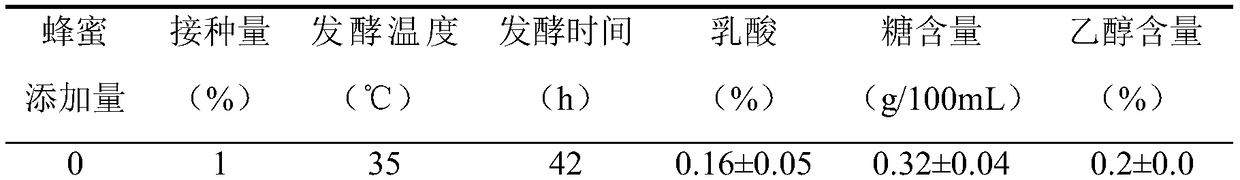

Embodiment 1

[0043] Weigh 200g each of apples, peaches, dragon fruit, blueberries, and mulberries respectively, wash them and soak them in 100ppm of ClO 2 Disinfect and sterilize the solution for 10 minutes; soak the fruit slices in a mixture of 1.0% sodium chloride and 0.8% cysteine for 15 minutes to protect the color; add 250 mL of distilled water to pulverize and beat; add 0.1mol / L to the obtained juice sodium citrate to adjust the pH value to 6.5; the enzymolysis process pectinase and cellulase are composed of 1:1 weight ratio, the amount added is 1.0% of the juice mass, the enzymolysis temperature is 60°C, and the enzymolysis time is 1.5 h, after the end of the enzymatic hydrolysis, the enzyme was killed in a boiling water bath for 5 minutes. Inoculate the freshly obtained juice with 8% low-ethanol producing yeasts (4% Saccharomyces cerevisiae and 4% Kluyveromyces lactis) and 2% acetic acid bacteria (1% Acetobacter acetobacter and 1% Acetobacter pasteurianus respectively) ), the fe...

Embodiment 2

[0046] Take by weighing 100g of juicy peach, 150g of kiwi, 150g of pear, 100g of pineapple, 100g of mulberry, and 200g of melon, and soak them in 80ppm of ClO 2 Disinfect and sterilize the solution for 15 minutes, soak the fruit slices in a mixture of 1.6% sodium chloride and 0.3% cysteine for 20 minutes to protect the color; add 200mL of distilled water to pulverize and beat; add 0.1mol / L to the obtained juice Sodium citrate to adjust the pH value to 6.2; the enzymolysis process pectinase and cellulase are composed of 2:1 weight ratio, the amount added is 0.8% of the juice mass, the enzymolysis temperature is 55°C, and the enzymolysis time is 2h After the end of enzymolysis, the enzyme was killed in a boiling water bath for 5 minutes; 10% low-ethanol-producing yeasts (respectively 2% Kluyveromyces lactis, 3% Hansenula botrytis and 5% fermented red yeast) and 4% acetic acid bacteria (respectively 1% Acetobacter aceti and 3% Acetobacter pasteurian), the fermentation temperatu...

Embodiment 3

[0049] Weigh 100g of red grape, 200g of melon, 80g of blueberry, 120g of mulberry, 200g of grapefruit, 150g of pineapple, 200g of strawberry, and 150g of grape, and soak them in 90ppm of ClO 2 The solution was sterilized for 13 minutes, and the fruit slices were soaked in a mixture of 1.3% sodium chloride and 0.5% cysteine for 10 minutes to protect the color; 300 mL of distilled water was added to crush and beat; the obtained juice was added with 0.1 mol / L sodium citrate to adjust the pH value to 6.0; the enzymolysis process consists of pectinase and cellulase in a weight ratio of 3:1, the addition amount is 1.2% of the juice mass, the enzymolysis temperature is 50°C, and the enzymolysis time is 2.5 h, after the end of the enzymolysis, the enzyme was killed in a boiling water bath for 5 minutes; 12% low ethanol-producing yeasts (5% Hansenula spp. and 7% Pichia fermentum) and 6% acetic acid bacteria were inserted into the fresh juice (Acetobacter aceti 3% and Acetobacter past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com