Cosmetic emulsion

A technology for cosmetics and emulsions, applied in cosmetics, cosmetic preparations, toiletry preparations, etc., can solve the problems of high cost of quinoa, uncommon use of quinoa, limited nutritional activity, and content of active ingredients in quinoa. Effects of emulsifying properties, improving purity, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment prepares the quinoa composition according to two kinds of processes:

[0036] Mix quinoa protein, yeast β-glucan and water at a mass ratio of 1:2:47, heat to 60°C for Maillard reaction until the grafting degree is 20%, lower the temperature to 45°C, add protease, Stir the enzymolysis until the degree of hydrolysis reaches 10%, heat to boiling to extinguish the enzyme for 15 minutes, separate the solid and liquid after cooling to remove the solid insoluble matter, separate the liquid with an ultrafiltration membrane and collect the filtrate with a molecular weight between 0.5-1kDa, freeze-dry to obtain quinoa Wheat composition1.

[0037] Mix quinoa protein and water at a mass ratio of 1:47, preheat to 45°C, add protease for enzymolysis until the degree of hydrolysis reaches 10%, heat to boiling for 15 minutes, lower the temperature to 60°C, and use the original added Based on the quality of quinoa protein, yeast β-glucan was added according to the mass r...

Embodiment 2

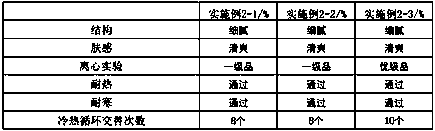

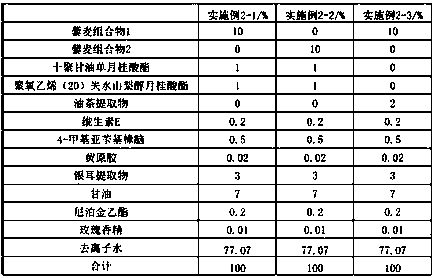

[0040] The quinoa composition 1 and quinoa composition 2 in Example 1 were prepared into emulsion according to the component ratios in Table 1.

[0041] Table 1 Example 2 Cosmetic Emulsion Composition

[0042]

[0043]The camellia oleifera extract of this example is prepared as follows: crush the camellia oleifera seed meal to below 40 mesh, add 10 times the quality water, shear at high speed with a shearing machine, mix evenly, and insert 0.1wt% of Aspergillus oryzae, stand and ferment at 25°C for 7 days, heat up to 90°C after fermentation, stir and reflux for extraction for 1 hour, filter through 200 mesh to remove the filter residue, then add 0.1wt% magnesium carbonate and stir evenly, filter with a filter medium with a pore size of less than 1 μm, and pass the filtrate through 10,000 molecular weight ultrafiltration membrane ultrafiltration, the retentate is concentrated to Brix25% to obtain camellia oleifera extract.

[0044] The cosmetic emulsion of the present embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com