A semiconductor heterojunction photocatalytic material and its preparation method and application

A photocatalytic material and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of fast electron and hole recombination, photo Reduced efficiency of catalytic capacity, reduced active carriers and other issues, to achieve the effect of wide source of raw materials, low cost, and improved activity efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

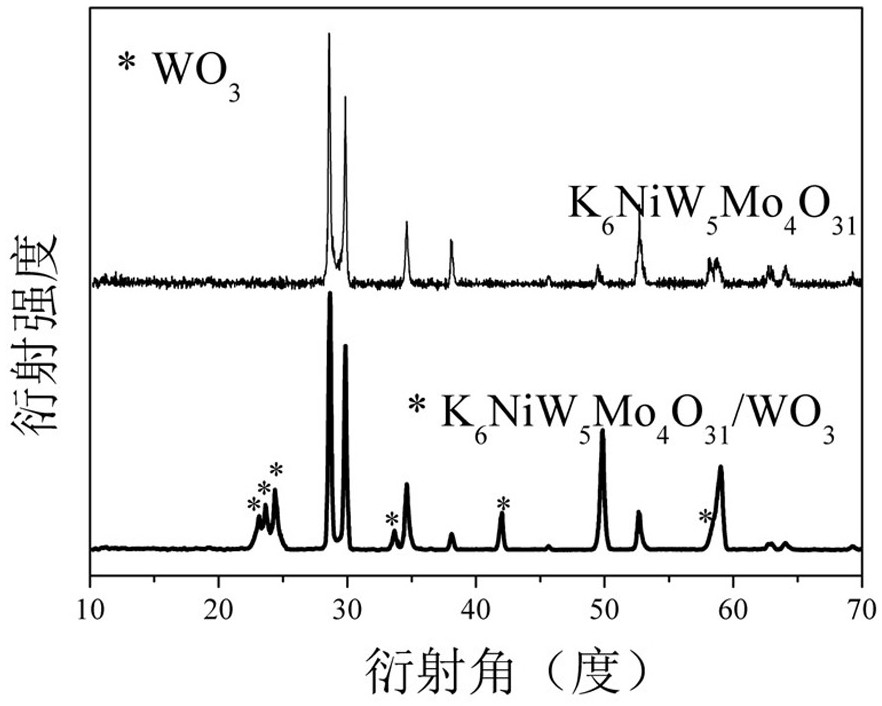

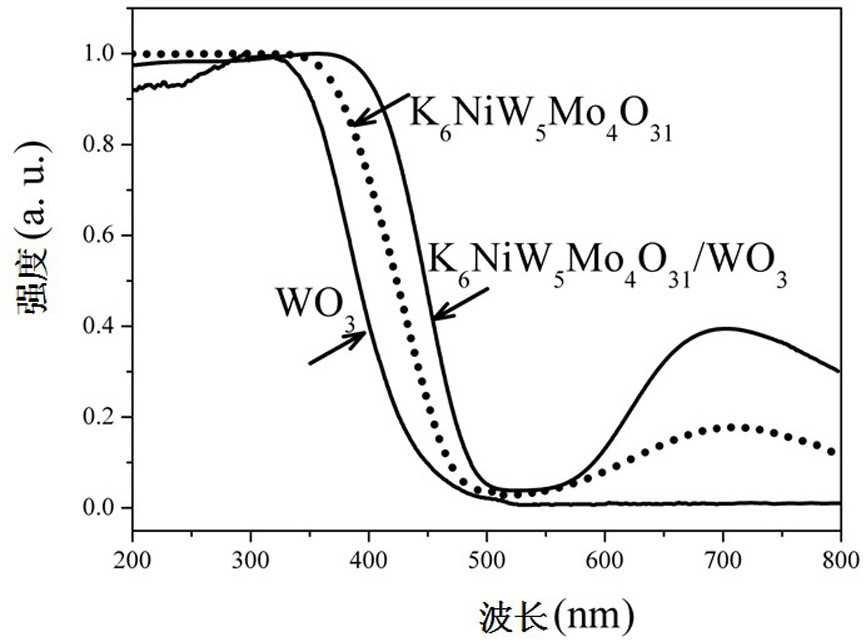

[0032] According to chemical formula K 6 NiW 5 Mo 4 o 31 The stoichiometric ratio of each element in the formula, respectively weigh potassium oxide K 2 O: 0.942 grams, nickel oxide NiO: 0.2490 grams, ammonium tungstate (NH 4 ) 6 W 7 o 24 ·6H 2 O: 7.24 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O: 2.352 grams, after grinding and mixing in an agate mortar, pre-calcined in an air atmosphere, the calcination temperature is 550 ° C, the calcination time is 10 hours, after natural cooling, grind to make it evenly mixed, and then calcined in an air atmosphere , the calcination temperature is 950°C, the calcination time is 1 hour, cooled naturally, and the precursor K is obtained after uniform grinding 6 NiW 5 Mo 4 o 31 .

[0033] will get K 6 NiW 5 Mo 4 o 31 Precursor and tungsten oxide 1.16 g WO 3 Mix by ball milling, and the ball milling time is 20 hours. The mixture obtained by ball milling was calcined in the air atmosphere, the calcining temperature w...

Embodiment 2

[0040] According to chemical formula K 6 NiW 5 Mo 4 o 31 The stoichiometric ratio of each element in the formula, respectively weigh potassium carbonate K 2 CO 3 : 2.76 grams, nickel oxide NiO: 0.497 grams, tungsten oxide WO 3 : 7.73 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O: 4.69g, after grinding and mixing uniformly in an agate mortar, pre-calcined in air atmosphere, the calcination temperature is 850°C, the calcination time is 1 hour, after natural cooling, grind to make it evenly mixed, and then calcined in air atmosphere , the calcination temperature was 850°C, the calcination time was 5 hours, cooled naturally, and the precursor K was obtained after uniform grinding 6 NiW 5 Mo 4 o 31 .

[0041] will get K 6 NiW 5 Mo 4 o 31 Precursor with tungsten oxide 0.25 g WO 3 Mix by ball milling, and the ball milling time is 1 hour. The mixture obtained by ball milling was calcined in the air atmosphere, the calcining temperature was 600°C, the calcining t...

Embodiment 3

[0043] According to chemical formula K 6 NiW 5 Mo 4 o 31 The stoichiometric ratio of each element in the formula, respectively weigh potassium carbonate K 2 CO 3 : 1.38 g, nickel nitrate Ni (NO 3 ) 2 ·6H 2 O: 0.97 g, ammonium tungstate (NH 4 ) 6 W 7 o 24 ·6H 2 O: 8.69 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O: 2.822g, after grinding and mixing uniformly in an agate mortar, pre-calcining in air atmosphere, the calcination temperature is 700°C, the calcination time is 3 hours, after natural cooling, grind to make it evenly mixed and then calcined in air atmosphere , the calcination temperature was 850°C, the calcination time was 7 hours, cooled naturally, and the precursor K was obtained after uniform grinding 6 NiW 5 Mo 4 o 31 .

[0044] Weigh 7.61 grams of ammonium tungstate (NH 4 ) 6 W 7 o 24 ·6H 2 O was dissolved in 50 ml distilled water, and the resulting K 6 NiW 5 Mo 4 o 31 The precursor was added to the solution, heated and stirred at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com