Micrometer carbon spheres and preparation method thereof

A carbon ball and surfactant technology, applied in the field of materials, can solve the problems of complex carbon ball process, high raw material waste rate, low product yield, etc., and achieve the effects of simple preparation process, easy centrifugal separation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a preparation method of micron carbon spheres, comprising the following steps:

[0036] (1) Add 6g of glucose into 40ml of water, stir until dissolved, then add 50mg of sodium dodecylsulfonate, stir for 15min to mix evenly, and obtain a mixed solution;

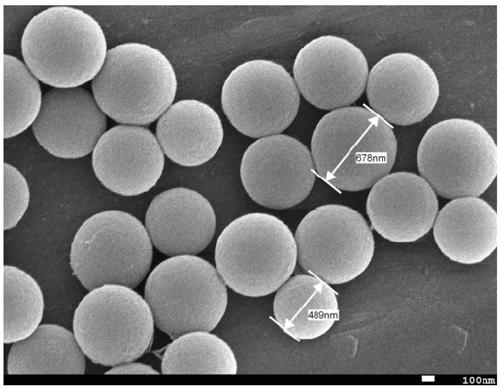

[0037] (2) Move the mixed solution described in step (1) into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 9 hours. After cooling to room temperature, centrifuge at a speed of 5000r / min for 6 minutes, and then wash with absolute ethanol first. Then wash with deionized water until the supernatant obtained by centrifugation after washing is clear, and dry the solid obtained after centrifugation in a vacuum oven at 80°C for 8 hours to obtain the particle size distribution between 0.489 and 0.678 μm micron carbon spheres, see figure 1 , the particle size distribution of carbon spheres is uniform, and it is an interconnected carbon sphere that is easy to be centri...

Embodiment 2

[0039] This embodiment provides a preparation method of micron carbon spheres, comprising the following steps:

[0040] (1) Add 6g of glucose into 40ml of water, stir until dissolved, then add 50mg of sodium dodecylsulfonate, stir for 15min to mix evenly, and obtain a mixed solution;

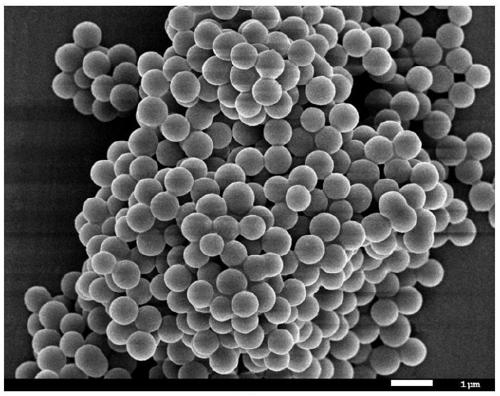

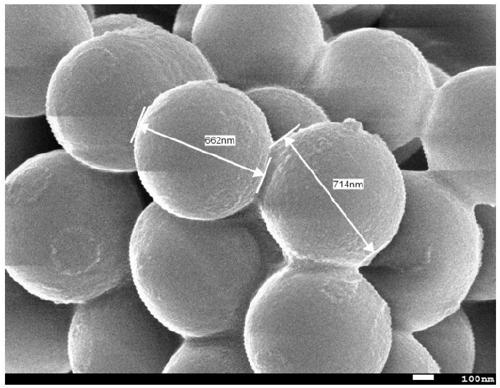

[0041] (2) Transfer the mixed solution described in step (1) into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 11 hours. After cooling to room temperature, centrifuge at a speed of 5000r / min for 6 minutes, and then wash with absolute ethanol first. Then wash with deionized water until the supernatant obtained by centrifugation after washing is clear, and dry the solid obtained after centrifugation in a vacuum oven at 80°C for 8 hours to obtain the particle size distribution between 0.662 and 0.714 μm micron carbon spheres, see figure 2 , image 3 , the particle size distribution of carbon spheres is uniform, and it is an interconnected carbon sphere that is...

Embodiment 3

[0043] This embodiment provides a preparation method of micron carbon spheres, comprising the following steps:

[0044] (1) Add 6 g of glucose into 40 ml of water, stir until dissolved, then add 50 mg of sodium dodecylsulfonate, stir for 15 min, then add 300 mg of cetyltrimethylammonium bromide, and continue stirring for 30 min to obtain a mixed solution;

[0045] (2) Move the mixed solution described in step (1) into a hydrothermal reaction kettle, react hydrothermally at 180°C for 8h, cool to room temperature, centrifuge at a speed of 5000r / min for 8min, and then wash with absolute ethanol first, Then wash with deionized water until the supernatant obtained by centrifugation after washing is clarified, and dry the solid obtained after centrifugation in a vacuum oven at 80°C for 8 hours to obtain the particle size distribution between 0.213 and 0.386 μm micron carbon spheres, see Figure 4 , Figure 5 , the particle size distribution of carbon spheres is uniform, and it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com