Recyclable carbon fiber reinforced epoxy resin composite material, preparation method thereof and application

A technology for recycling carbon fiber and epoxy resin, which is applied in the field of polymer materials to achieve the effects of good controllability, easy implementation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned recyclable carbon fiber reinforced epoxy resin composite material, which includes:

[0041] Pre-cure after uniformly mixing the aldehyde-containing monofunctional epoxy resin, curing agent, curing accelerator, epoxy reactive diluent and solvent to obtain a mixed solution, wherein the aldehyde-containing monofunctional epoxy resin and The curing agent can react to form a Schiff base structure;

[0042] Immersing the carbon fiber in the mixed solution, and then removing the solvent to obtain a carbon fiber prepreg;

[0043] The carbon fiber prepreg is subjected to heat press treatment and post-curing treatment to obtain a recyclable carbon fiber reinforced epoxy resin composite material.

[0044] As one of the preferred embodiments, the mass ratio of the aldehyde-containing monofunctional epoxy resin, curing agent, curing accelerator, epoxy reactive diluent, carb...

Embodiment 1

[0068] (1) Mix 100g of aldehyde-containing monofunctional epoxy resin 1, 80g of ethylenediamine, and 10g of ethanol and pre-cure at 50°C for 50 minutes, soak the carbon fiber unidirectional cloth in the mixed solution for 1min, and then place it in a blast oven The solvent was volatilized at 30°C for 2 hours to obtain a carbon fiber prepreg.

[0069] (2) 10 g of carbon fiber prepreg was hot-pressed at 180° C. under a pressure of 0.5 MPa for 10 minutes, and then post-cured in a vacuum oven at 180° C. for 2 hours to obtain a carbon fiber-reinforced epoxy resin composite material.

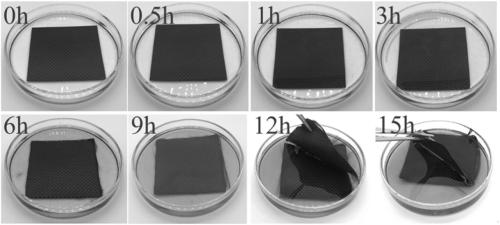

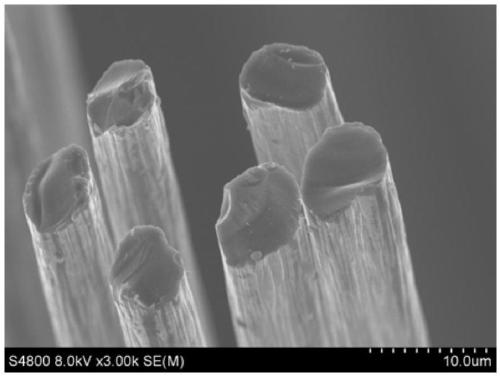

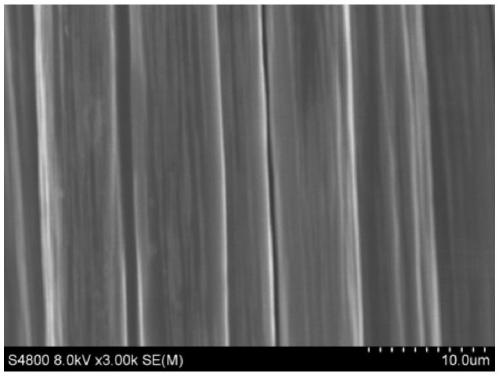

[0070] After testing, the carbon fiber reinforced epoxy resin composite material has a tensile strength of 3600MPa, a tensile modulus of 29GPa, and a glass transition temperature of 180°C, and it can be degraded in a mixed solvent of 0.1M hydrochloric acid and methanol, such as figure 1 shown. The morphology of carbon fibers before and after recycling was characterized by scanning electron microscopy...

Embodiment 2

[0072] Mix 100g of aldehyde-containing monofunctional epoxy resin 1, 90g of butanediamine, 2g of triethylamine, 3g of n-butyl glycidyl ether, and 30g of short fibers, and then cure them at 160°C for 2 hours. After curing for 2 hours, the carbon fiber composite material is obtained.

[0073] After testing, the carbon fiber reinforced epoxy resin composite material has a tensile strength of 800MPa, a tensile modulus of 16GPa, and a glass transition temperature of 140°C, and it can be degraded in a mixed solvent of 0.1M hydrochloric acid and methanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com