Preparation method of recoverable and regenerable carbon net combined powder non-metal mineral porous water purifying material

A technology of non-metallic minerals and regenerated carbon, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of overall performance decline of adsorbent, complex preparation process, long replacement cycle, etc., to achieve enhanced adsorption Water purification performance, simple operation process, easy recycling and regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

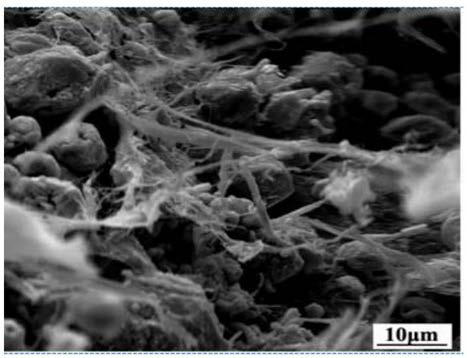

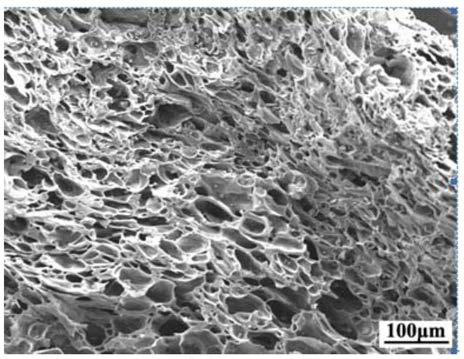

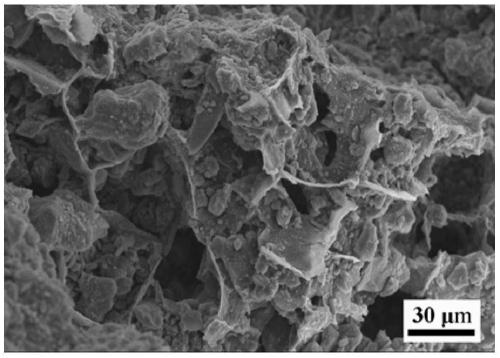

Image

Examples

Embodiment 1

[0023] Zeolite powder and bentonite powder with a particle size of 200 mesh are used as powder non-metallic mineral raw materials, wood chips and starch are used as carbon network forming agents, and zinc chloride is used as carbonization aid. The mass ratio of each component is as follows: 80% of zeolite powder, 5% of bentonite powder, 11.5% of sawdust, 3% of starch, and 0.5% of zinc chloride. The raw materials are mechanically mixed and stirred evenly for later use. Add an appropriate amount of water and silica sol to the mixed raw materials, and granulate them into particles with a particle size of 3mm-5mm by mechanical means. The granules obtained by granulation were dried in an oven at 105°C for 5 hours, and then placed in an electric furnace with nitrogen atmosphere for heat treatment and carbonization. The target carbonization temperature was 500°C, the heating rate was 2°C / min, and the target temperature was kept for 2 hours. After the heat preservation is completed, ...

Embodiment 2

[0025] Diatomite powder and bentonite powder with a particle size of 200 mesh are used as powder non-metallic mineral raw materials, resin powder and starch are used as carbon network forming agents, and nickel chloride is used as carbonization aid. The mass ratio of each component is as follows: 70% of diatomite powder, 10% of bentonite powder, 13% of resin powder, 5% of starch, and 2% of nickel chloride. The raw materials are mechanically mixed and stirred evenly for later use. Then add the aqueous solution to the powder that has been mixed before and mix it evenly to form a plastic clay, and then granulate it into particles with a particle size of 10mm-20mm or make a product with a certain shape. Dry the obtained granules or products in an oven at 105°C for 5 hours, and then put them into an electric furnace with nitrogen atmosphere for heat treatment and carbonization. The target carbonization temperature is 800°C, the heating rate is 5°C / min, and the target temperature is...

Embodiment 3

[0027] Zeolite powder and bentonite with a particle size of 325 mesh are used as powder non-metallic ore raw materials, wood chips are used as carbon network forming agent, and ferric chloride is used as carbonization aid. The mass ratio of each component is as follows: 88% of zeolite powder, 5% of bentonite powder, 4% of polyvinyl alcohol powder, 2% of resin powder, and 1% of ferric chloride. First mix the raw materials evenly, then add the aqueous solution to the raw materials to granulate into particles with a particle size of 5mm-10mm or products with a certain shape. Then dry the particles or products in an oven at 105°C for 5h, and then put them into an electric furnace with a carbon dioxide atmosphere for heat treatment and carbonization. The target carbonization temperature is 400°C, the heating rate is 3°C / min, and the target temperature is kept for 2h. After the heat preservation is over, continue to pass carbon dioxide gas until it is cooled to room temperature to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com