Preparation method of silicon carbide ceramic precursor polycarbosilane

A technology of silicon carbide ceramics and polycarbosilane, which is applied in the field of silicon carbide ceramics, can solve the problems of polycarbosilane carbon-rich reactivity, high raw material cost, and difficulty in obtaining SiC ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

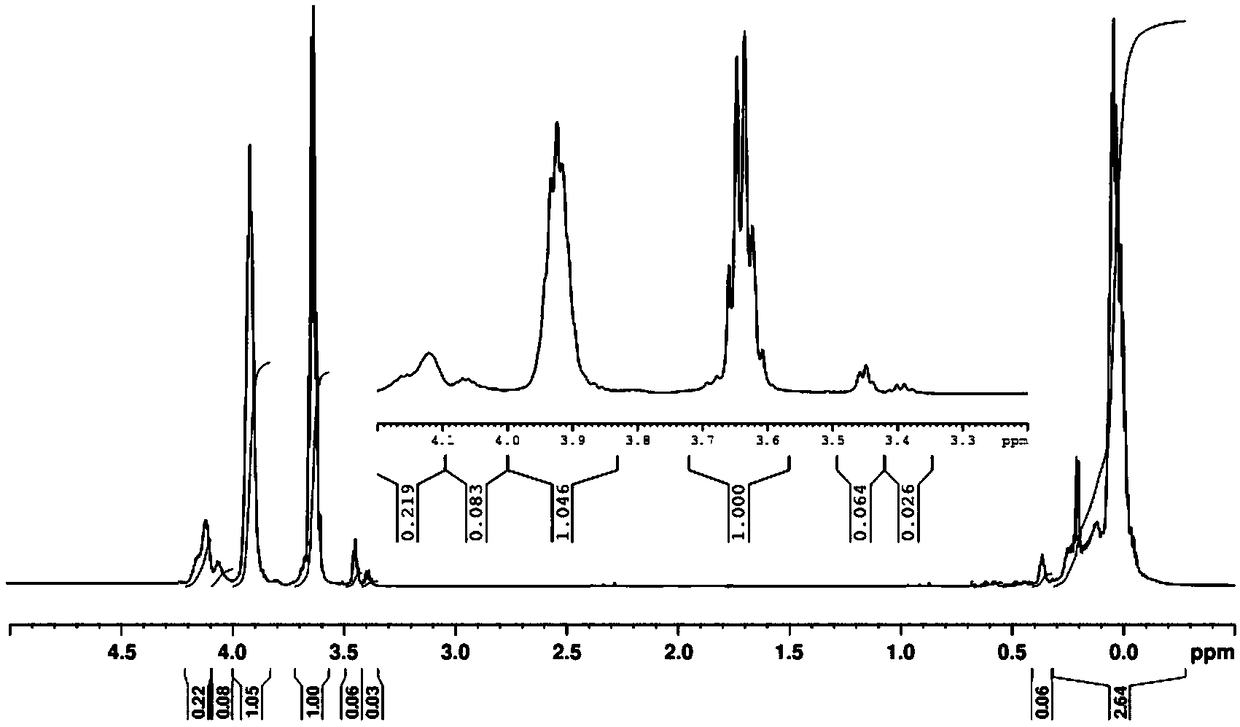

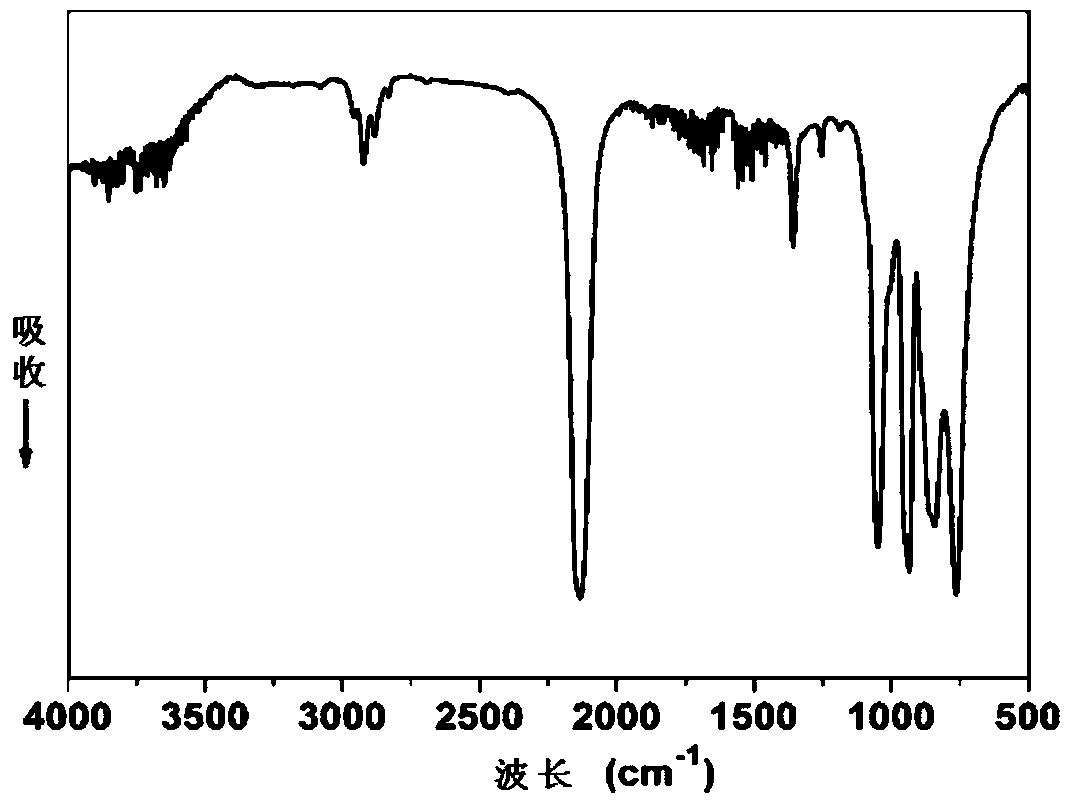

[0069] The structural formula is [SiH 2 CH 2 ] n Preparation of polycarbosilane.

[0070] Under nitrogen protection and room temperature, add sodium metal (1mol) and xylene (500mL) into a four-necked flask equipped with a mechanical stirrer, thermometer, nitrogen introduction tube, condenser and dropping funnel, stir and heat to 100°C. After the temperature became constant, chloromethyltrimethoxysilane (0.5 mol) was added in batches, and then the reaction was continued for 3 hours. After the temperature of the solution drops to room temperature, the upper layer solution is transferred to a centrifuge tube by pouring, and then centrifuged at a high speed to remove the remaining solid suspension. The solvent xylene was recovered by distillation under reduced pressure. Tetrahydrofuran (500 mL) dewatered by sodium was added to the obtained intermediate product, and the temperature was raised to 40°C. Then, the reducing reagent lithium aluminum hydride (0.35 mol) was added in batches...

Embodiment 2

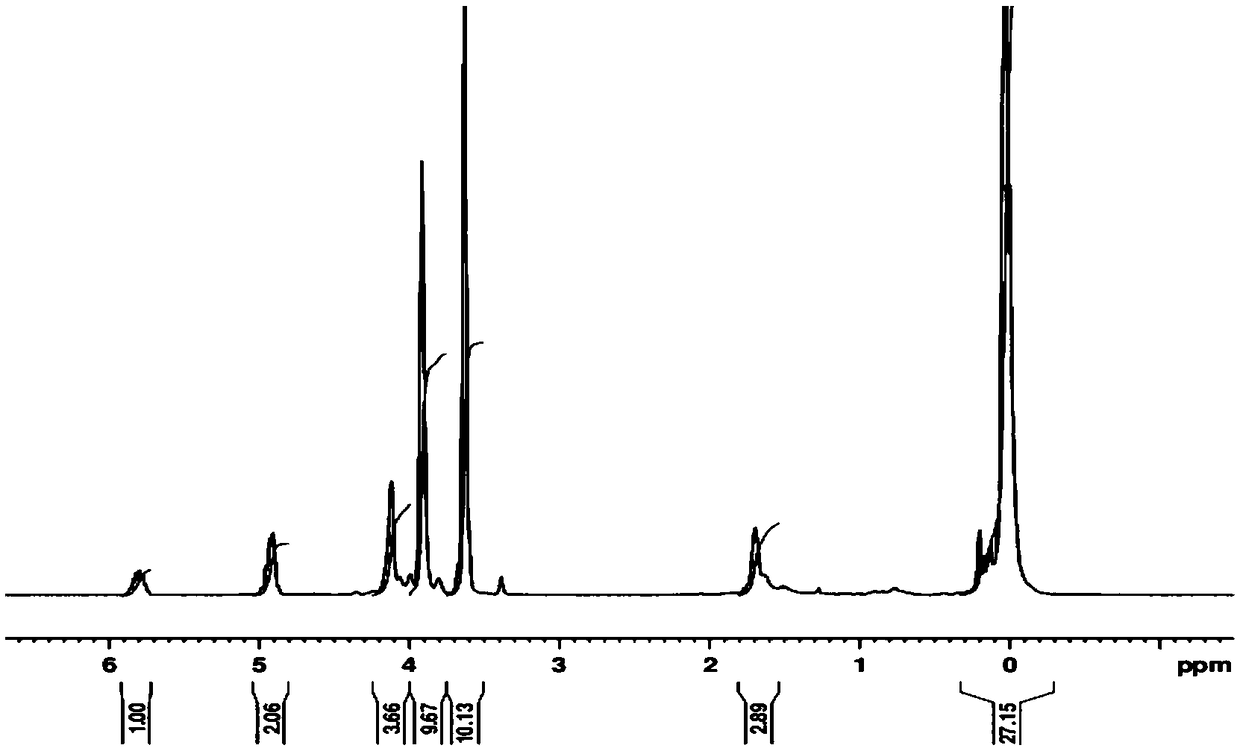

[0076] The structural formula is {[SiH 2 CH 2 ] 9 -[SiH(CH 2 -CH=CH 2 )CH 2 ] 1 } n Preparation of polycarbosilane.

[0077] Under the protection of nitrogen and room temperature, in a four-necked flask equipped with a mechanical stirrer, thermometer, nitrogen introduction tube, condenser and dropping funnel, add sodium metal (1mol), chloropropylene (0.05mol), size 10~ 30nm copper powder (0.01mol), chloromethyltrimethoxysilane (0.05mol) and cyclopentylmethyl ether (500mL) were added, stirred and heated to 100°C. After the temperature became constant, chloromethyltrimethoxysilane (0.4 mol) was added in batches, and then the reaction was continued for 4 hours. After the temperature of the solution drops to room temperature, add trimethylchlorosilane (0.6mol) and stir for 0.5 hours, and then extract trimethylchlorosilane and trimethylmonomethoxy at 35℃ through a circulating water pump (vacuum degree of 0.095MPa) Silane. The resulting solution was heated to 50°C, and then the reduc...

Embodiment 3

[0083] The structural formula is {[SiH 2 CH 2 ] 9 -[SiH(CH 2 -CH=CH 2 )CH 2 ] 1 } n Preparation of hyperbranched polycarbosilane:

[0084] Under the protection of nitrogen and room temperature, in a four-necked flask equipped with a mechanical stirrer, thermometer, nitrogen introduction tube, condenser and dropping funnel, add sodium metal (1mol), chloropropylene (0.05mol), size 10~ 30nm copper powder (0.05mol) and cyclopentyl methyl ether (500mL) were added, stirred and heated to 100°C. After the temperature is constant, a mixture of chloromethyltrimethoxysilane (0.42mol) and tris(chloromethyl)monomethoxysilane (0.01mol) is added in batches, and then the reaction is continued for 3 hours. After the temperature of the solution drops to room temperature, add trimethylchlorosilane (0.6mol) and stir for 0.5 hours, and then extract trimethylchlorosilane and trimethylmonomethoxy at 35℃ through a circulating water pump (vacuum degree of 0.095MPa) Silane. The resulting solution was he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com