Polishing protecting wax for new energy automobile and preparation method of polishing protecting wax

A new energy vehicle, light protection technology, applied in chemical instruments and methods, polishing compositions, etc., can solve the problems of high cost, paint gloss and short protection time, etc., achieve good protection effect, gloss and long protection time, Good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

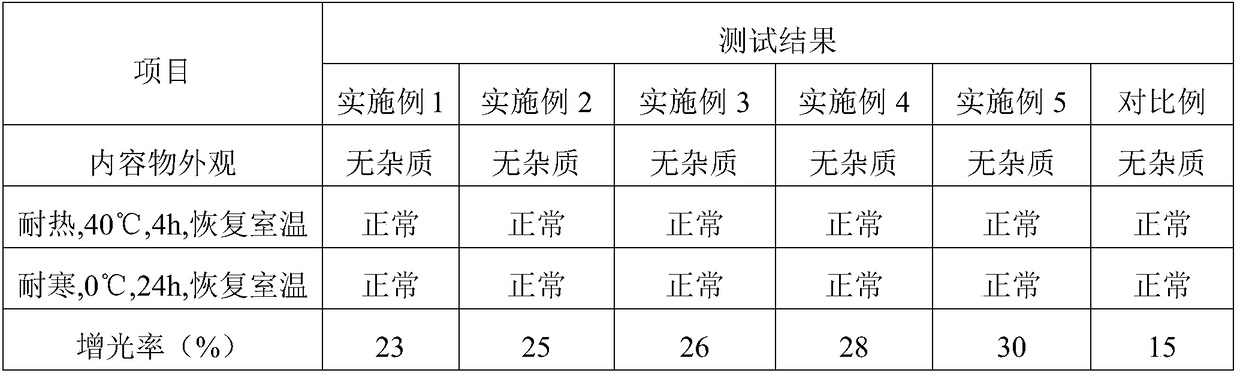

Examples

Embodiment 1

[0029] A new energy vehicle glazing protective wax, which is made of the following raw materials in parts by weight: 25 parts of polydimethylsiloxane copolymer based on modified paraffin, N-(4-sulfonic acid butyl)- 4-(4-(4-(Dipentylamino)phenyl)butadienyl)pyridine internal salt modified oleic acid 5 parts, polyethylene wax powder 1 part, carnauba wax 1 part, aliphatic hydrocarbon solvent 40 parts , 2 parts of sodium dodecylbenzenesulfonate.

[0030] The aliphatic hydrocarbon solvent has a boiling range of 130°C.

[0031] The preparation method of the N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino)phenyl) butadienyl) pyridine internal salt modified oleic acid comprises the steps of: Under a nitrogen atmosphere, 17.7 g of N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino) phenyl) butadienyl) pyridine inner salt and 10 g of oleic acid were dissolved in A solution was formed in 100 g of dimethyl sulfoxide, and then the solution was added to a three-necked flask equipped with a ...

Embodiment 2

[0037] A new energy automobile glazing protective wax, which is made of the following raw materials in parts by weight: 27 parts of polydimethylsiloxane based copolymers of modified paraffin, N-(4-sulfonic acid butyl)- 6 parts of 4-(4-(4-(dipentylamino)phenyl)butadienyl)pyridine internal salt modified oleic acid, 2 parts of polyethylene wax powder, 2 parts of carnauba wax, 43 parts of aliphatic hydrocarbon solvent , 3 parts of polyoxypropylene polyvinyl glyceryl ether.

[0038] The boiling range of the aliphatic hydrocarbon solvent is 150°C.

[0039] The preparation method of the N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino)phenyl) butadienyl) pyridine internal salt modified oleic acid comprises the steps of: Under a helium atmosphere, 17.7 g of N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino) phenyl) butadienyl) pyridine inner salt and 10 g of oleic acid were dissolved Form a solution in 115g of N,N-dimethylformamide, then add the solution into a three-necked flask equ...

Embodiment 3

[0045] A new energy automobile glazing protective wax, which is made of the following raw materials in parts by weight: 30 parts of polydimethylsiloxane based copolymers of modified paraffin, N-(4-sulfonic acid butyl)- 7 parts of 4-(4-(4-(dipentylamino)phenyl)butadienyl)pyridine internal salt modified oleic acid, 3 parts of polyethylene wax powder, 3 parts of carnauba wax, 45 parts of aliphatic hydrocarbon solvent , 3 parts of nonylphenol polyoxyethylene ether.

[0046] The aliphatic hydrocarbon solvent has a boiling range of 180°C.

[0047] The preparation method of the N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino)phenyl) butadienyl) pyridine internal salt modified oleic acid comprises the steps of: Under neon gas atmosphere, dissolve 17.7g of N-(4-sulfonic acid butyl)-4-(4-(4-(dipentylamino)phenyl)butadienyl)pyridine inner salt with 10g of oleic acid Form a solution in 125g of N-methylpyrrolidone, then add the solution into a three-necked flask equipped with a reflux c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com