A kind of preparation method of dihydropyridine crude drug

A technology of dihydropyridine and raw materials, which is applied in the field of synthesis and preparation of pharmaceutical raw materials, can solve the problems of high energy consumption in distillation and recovery of solvents, cumbersome post-processing operations, and difficulty in large-scale production, and achieve a good operating environment for workers and post-processing Simple operation, good for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

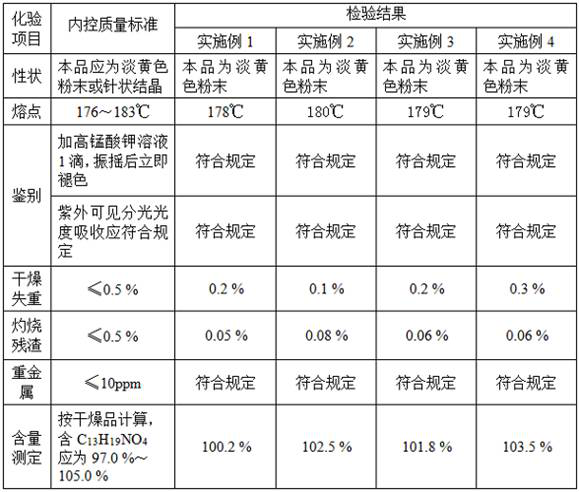

Examples

Embodiment 1

[0020] A kind of preparation method of dihydropyridine crude drug, concrete steps are as follows:

[0021] (1) Put 130kg of ethyl acetoacetate and 140kg of urotropine into the reaction kettle, control the temperature at 15-20°C, stir and mix for 0.5 hours; raise the temperature to 30-35°C, slowly add 183kg of ethanolamine dropwise, and control the dropping speed After 1 hour of dropwise addition, the temperature was raised to 65-70°C, and the heat preservation reaction was carried out for 2.5 hours; the temperature was slowly lowered to 0-10°C, heat preservation and crystallization were carried out for 3 hours, and centrifugation was carried out at a temperature of 3-5°C to obtain 262 kg of crude dihydropyridine;

[0022] (2) Add 786kg of ethanol to the reaction kettle, put in 262kg of crude dihydropyridine, heat and stir to dissolve, add dropwise glacial acetic acid to adjust PH=7; add 2.62kg of activated carbon, stir for one hour, then press into the crystallization kettle, t...

Embodiment 2

[0026] A kind of preparation method of dihydropyridine crude drug, concrete steps are as follows:

[0027] (1) Put 168kg of ethyl acetoacetate and 140kg of urotropine into the reaction kettle, control the temperature at 15-20°C, stir and miscible for 0.5 hours; raise the temperature to 30-35°C, slowly add 213.5kg of ethanolamine dropwise, and control the dropwise Acceleration, dropwise addition in 1 hour, heat up to 65-70°C, keep warm for 2.5 hours; slowly cool down to 0-10°C, keep warm for crystallization for 3 hours, control the temperature at 3-5°C and centrifuge to obtain 274kg of crude dihydropyridine;

[0028] (2) Add 822kg of ethanol to the reaction kettle, put in 274kg of crude dihydropyridine, heat and stir to dissolve, add dropwise glacial acetic acid to adjust PH=7; add 2.74kg of activated carbon, stir for one hour, then press into the crystallization kettle, temperature control Stir and crystallize at 0-5°C, stir and crystallize for 2 hours, and centrifuge at a con...

Embodiment 3

[0032] A kind of preparation method of dihydropyridine crude drug, concrete steps are as follows:

[0033] (1) Put 169kg of ethyl acetoacetate and 140kg of urotropine into the reaction kettle, control the temperature at 15-20°C, stir and miscible for 0.5 hours; raise the temperature to 30-35°C, slowly add 189.1kg of ethanolamine dropwise, and control the dropwise Acceleration, dropwise addition in 1 hour, heat up to 65-70°C, keep warm for 2.5 hours; slowly cool down to 0-10°C, keep warm for crystallization for 3 hours, control the temperature at 3-5°C and centrifuge to obtain 263kg of crude dihydropyridine;

[0034] (2) Add 1052kg of ethanol to the reaction kettle, put in 263kg of crude dihydropyridine, heat and stir to dissolve, add dropwise glacial acetic acid to adjust PH=7; add 2.63kg of activated carbon, stir for one hour, then press into the crystallization kettle, temperature control Stir and crystallize at 0-5°C, stir and crystallize for 2 hours, and centrifuge at a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com