Method for producing Chinese caterpillar fungus mycelium powder through fermentation

A technology for cordyceps sinensis mycelium and cordyceps sinensis fungus is applied in the field of fermentation and production of cordyceps sinensis mycelium powder, which can solve problems such as low mycelium yield, reduce production cost, solve low yield, save manpower and material resources and equipment occupancy rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

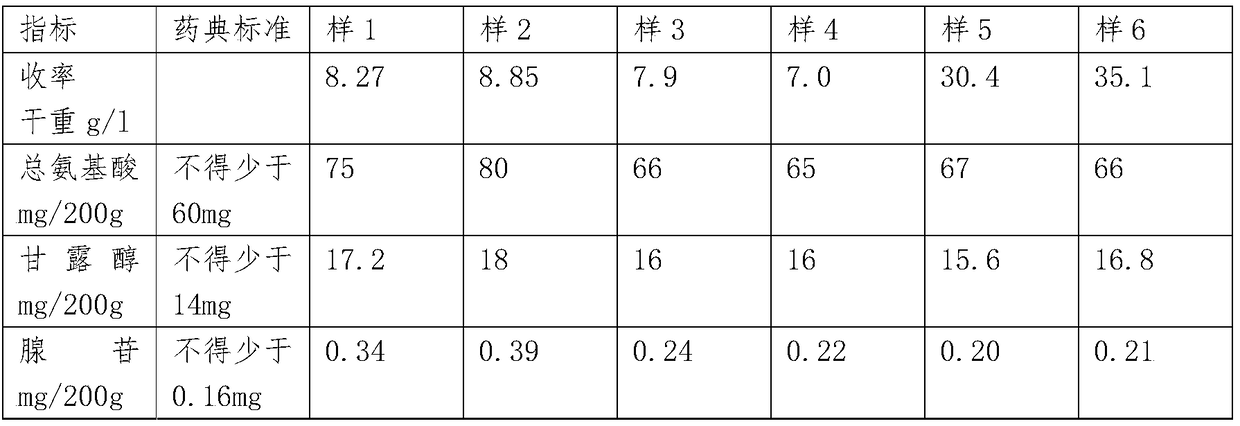

Examples

Embodiment 1

[0036] Preparation of slant seeds: DCH slant medium: 5.0% sucrose, 0.3% yeast powder, 1.0% tryptone, 1.0% agar powder, with an inorganic ion solution of pH 5.6-6.0 (0.5 grams of magnesium sulfate, 1 gram of potassium dihydrogen phosphate , 1 g of sodium chloride, 0.3 g of calcium chloride, 0.01 g of manganese sulfate, 0.01 g of zinc sulfate, 0.01 g of ferrous sulfate, 0.01 g of copper sulfate, and 1000 ml of distilled water). After sterilizing and cooling down, the activated Cordyceps sinensis strain is inoculated on the slant medium, and cultured at 15-18° C. for 35 days. The strain is selected from the Industrial Microorganism Culture Collection Management Center CICC, No. 14088.

[0037] Preparation of shake flask seeds: shake flask medium: glucose 1.0%, corn flour 2.5%, molasses 1.0%, potato 2.0%; live silkworm chrysalis 6.0%, soybean sprout powder 0.5%, yeast powder 0.2%, bran 1.0%; sulfuric acid Magnesium 0.01%, potassium dihydrogen phosphate 0.1%, and the rest is water...

Embodiment 2

[0045] Preparation of slant seeds: DCH slant medium: 5.0% sucrose, 0.3% yeast powder, 1.0% tryptone, 1.0% agar powder, with an inorganic ion solution of pH 5.6-6.0 (0.5 grams of magnesium sulfate, 1 gram of potassium dihydrogen phosphate , 1 g of sodium chloride, 0.3 g of calcium chloride, 0.01 g of manganese sulfate, 0.01 g of zinc sulfate, 0.01 g of ferrous sulfate, 0.01 g of copper sulfate, and 1000 ml of distilled water). The activated bacteria were inoculated on the slant medium and cultured at 15-18°C for 33 days. The strain is selected from the Industrial Microorganism Culture Collection Management Center CICC, No. 14088.

[0046] Preparation of shake flask seeds: shake flask medium: glucose 1.5%, corn flour 1.5%, molasses 1.5%, potato 3.0%; live silkworm chrysalis 4.0%, soybean sprout powder 1.0%, yeast powder 1.0%, bran 1.5%; sulfuric acid Magnesium 0.02%, potassium dihydrogen phosphate 0.05%, and the rest is water. First cut potatoes into small pieces, cut silkworm...

Embodiment 3

[0054] Preparation of slant seeds: DCH slant medium: 5.0% sucrose, 0.3% yeast powder, 1.0% tryptone, 1.0% agar powder, with an inorganic ion solution of pH 5.6-6.0 (0.5 grams of magnesium sulfate, 1 gram of potassium dihydrogen phosphate , 1 g of sodium chloride, 0.3 g of calcium chloride, 0.01 g of manganese sulfate, 0.01 g of zinc sulfate, 0.01 g of ferrous sulfate, 0.01 g of copper sulfate, and 1000 ml of distilled water). The activated bacteria were inoculated on the slant medium and cultured at 15-18°C for 34 days. The strain is selected from the Industrial Microorganism Culture Collection Management Center CICC, No. 14088.

[0055] Preparation of shake flask seeds: shake flask medium: glucose 1.5%, corn flour 2.0%, molasses 1.0%, potato 5.0%; live silkworm chrysalis 5.0%, soybean sprout powder 1.0%, yeast powder 0.4%, bran 1.5%; sulfuric acid Magnesium 0.01%, potassium dihydrogen phosphate 0.02%, and the rest is water. First cut potatoes into small pieces, cut silkworm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com