Nitrogen-doped graphene fiber non-woven fabric and preparation method thereof

A technology of graphene fibers and non-woven fabrics, which is applied in the fields of fiber chemical characteristics, non-woven fabrics, textiles and papermaking, etc. It can solve problems that have not been reported, poor affinity of aqueous electrolytes, electrochemical activity limitations, etc., and achieve wide application Prospect, simple preparation method, effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The graphene oxide / water solution with a concentration of 5 mg / mL is used as the spinning solution, wherein 10% of the mass fraction of polyvinylpyrrolidone is added, and the mixed solution of calcium chloride / water / ethanol (mass ratio 20:300:100) is coagulation bath for continuous wet spinning.

[0026] (2) The obtained graphene oxide fibers were left at room temperature for 12 hours, and then vacuum-dried at a temperature of 100° C. for 3 hours.

[0027] (3) Disperse the dried composite fibers in an ethanol solution, and grind them with a high-speed shear mixer to obtain a dispersion of short fibers.

[0028] (4) Deposit composite short fibers on the filter, and vacuum filter to dryness to obtain graphene oxide / polyvinylpyrrolidone composite fiber non-woven fabric.

[0029] (5) Carrying out heat treatment at 1000° C. to the prepared composite fiber nonwoven fabric to obtain nitrogen-doped graphene fiber nonwoven fabric.

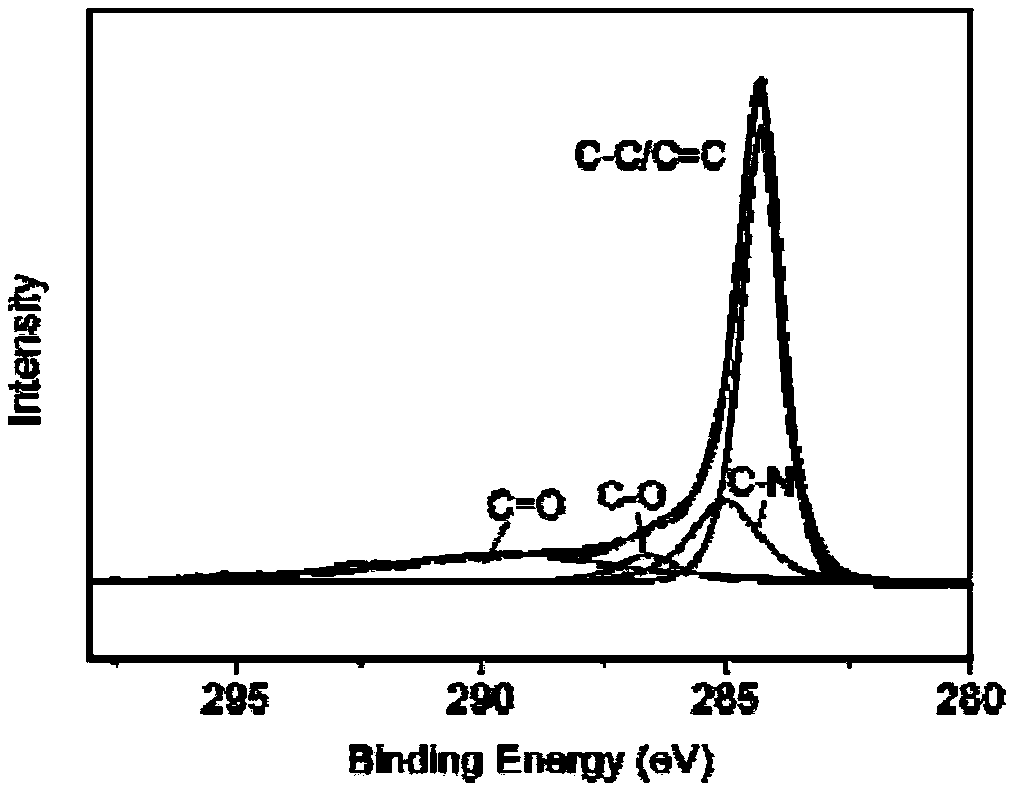

[0030] figure 1 a is the surface morpho...

Embodiment 2

[0032] (1) Graphene oxide / N with a concentration of 5 mg / mL, N-dimethylformamide solution is used as spinning solution, wherein 10% urea is added by mass fraction, and ethyl acetate is used as coagulation bath for continuous wet spinning .

[0033] (2) The obtained graphene oxide fiber was placed at room temperature for 14 hours, and then vacuum-dried at 100° C. for 3 hours.

[0034] (3) Disperse the dried composite fibers in an ethanol solution, and grind them with a high-speed shear mixer to obtain a dispersion of short fibers.

[0035] (4) Deposit composite short fibers on the filter screen, and vacuum filter to dryness to obtain graphene oxide / urea composite fiber nonwoven fabric.

[0036] (5) Carry out heat treatment at 800° C. to the prepared composite fiber non-woven fabric to obtain nitrogen-doped graphene fiber non-woven fabric.

[0037] After the above steps, the nitrogen content of the obtained graphene fiber non-woven fabric is about 6%, and the capacitance value...

Embodiment 3

[0039] Steps 1-5 are the same as in Example 2, the polymer added to the spinning solution is melamine with a mass fraction of 5%, and the final heat treatment temperature is 1000°C. The nitrogen content of the obtained graphene fiber nonwoven fabric is about 3%.

[0040] The capacitance value of this graphene fiber nonwoven electrode is 184F / g (0.1A / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com