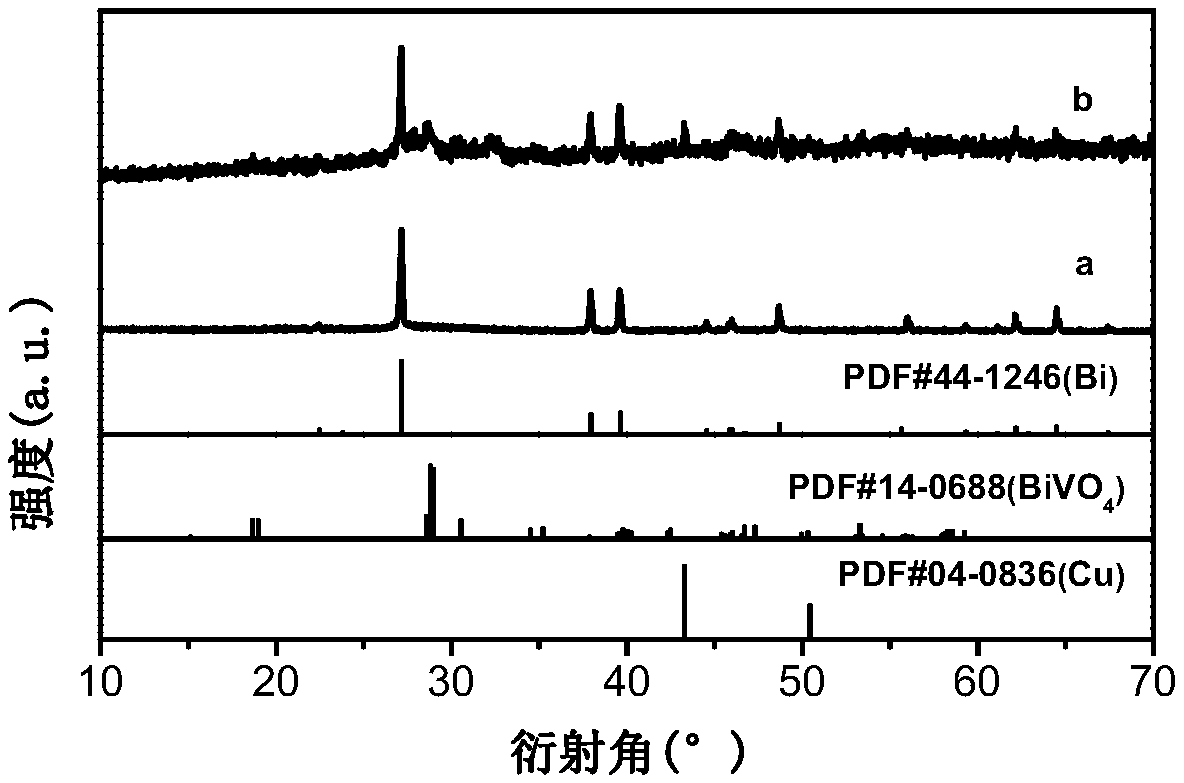

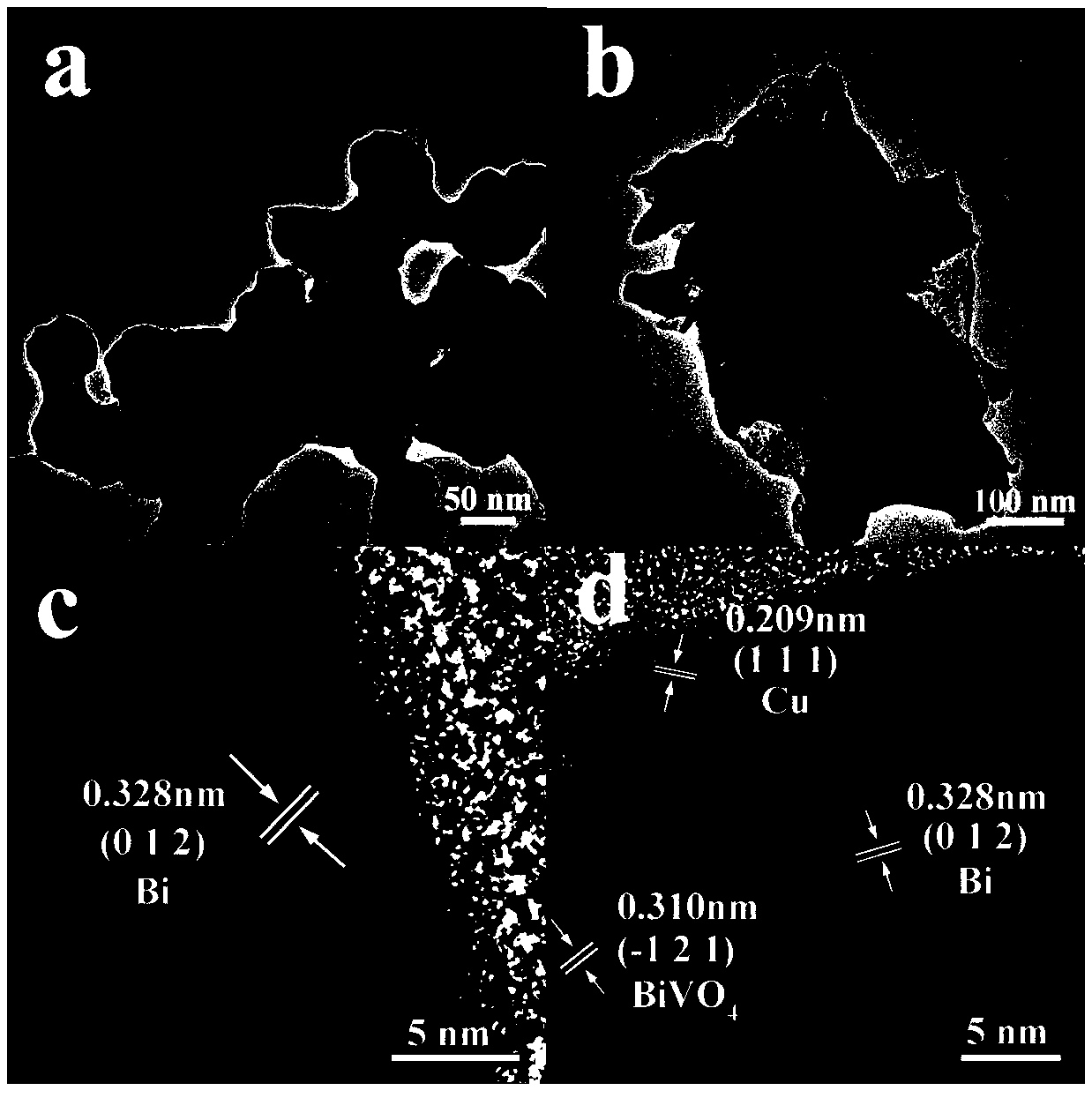

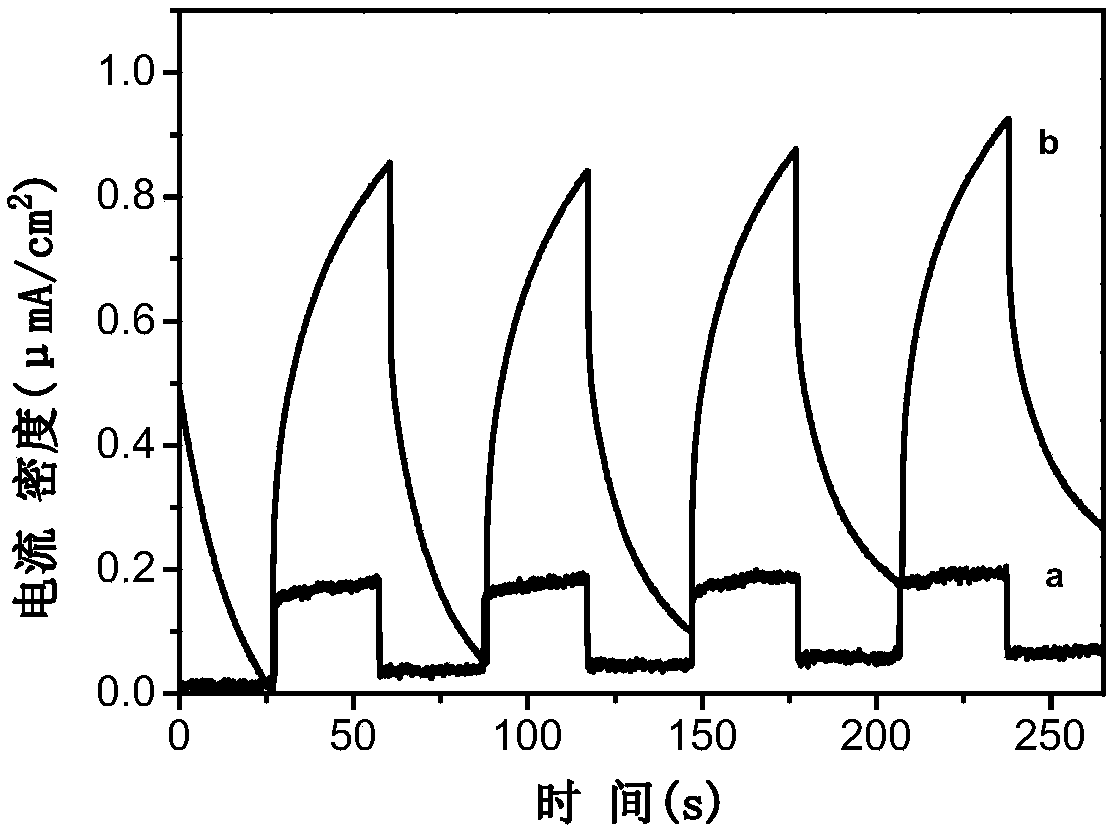

Preparation and application of copper-bismuth/bismuth vanadate composite photocatalyst

A technology of bismuth vanadate and compound light, which is applied in the field of photocatalysis, can solve the problems of narrow energy band structure, easy recombination of photogenerated holes and electrons, and small specific surface area, so as to achieve enhanced synergistic effect, improved photocatalytic performance, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of reticular bismuth / bismuth vanadate composite nanostructure: take 1mmol Bi(NO 3 ) 3 ·5H 2 Dissolve the O crystals in 15mL of ethylene glycol solution, stir to make it completely dissolve, and form a transparent solution, which is recorded as A solution; take 1mmol NH 4 VO 3 Dissolve the powder in 15mL of ethylene glycol solution, stir to dissolve it completely, and form a transparent solution, which is recorded as solution B; add solution B dropwise to solution A to obtain a light yellow mixed solution, transfer it to 40mL after stirring for 30 minutes In a high-pressure reactor, the reactor was placed in an oven at 180°C and reacted for 10 hours. Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 The ratio of the amount of substances is 1:1. The obtained product was alternately washed with ethanol and water, and dried in a vacuum oven at 60° C. for 6 hours to obtain bismuth / bismuth vanadate.

Embodiment 2

[0042] Preparation of reticular bismuth / bismuth vanadate composite nanostructure: take 1mmol Bi(NO 3 ) 3 ·5H 2 Dissolve the O crystals in 15mL of ethylene glycol solution, stir to make it completely dissolve, and form a transparent solution, which is recorded as A solution; take 1mmol NH 4 VO 3 Dissolve the powder in 15mL of ethylene glycol solution, stir to dissolve it completely, and form a transparent solution, which is recorded as solution B; add solution B dropwise to solution A to obtain a light yellow mixed solution, transfer it to 40mL after stirring for 30 minutes In a high-pressure reactor, the reactor was placed in an oven at 160°C, and reacted for 8 hours. Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 The ratio of the amount of substances is 1:1. The obtained product was alternately washed with ethanol and water, and dried in a vacuum oven at 60° C. for 6 hours to obtain bismuth / bismuth vanadate.

Embodiment 3

[0044] Preparation of copper-bismuth / bismuth vanadate composite photocatalyst: take 0.1310 g of bismuth / bismuth vanadate prepared in Example 1 of the present invention and disperse in 30mL6.7mmol / L copper acetate solution, disperse, and constantly stir, the solution is stirred After 1h, it was transferred to a 40mL high-pressure reactor, and the reactor was placed in an oven at 120°C for 6 hours of reaction. The synthesized brown-yellow sample is the copper-bismuth / bismuth vanadate composite photocatalyst. The synthesized samples were washed alternately with ethanol and water, and dried in a vacuum oven at 60 °C for 6 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com