Heavy oil pollution cleansing agent and preparation method thereof

A technology of oil stain cleaning agent and heavy oil, which is applied in the direction of detergent composition, detergent compounding agent, chemical instruments and methods, etc., can solve the problems of poor sustainability and safety, troublesome wastewater treatment, and reduced service life of workpieces, etc., to achieve Improve the rationality of use, prolong the storage time, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

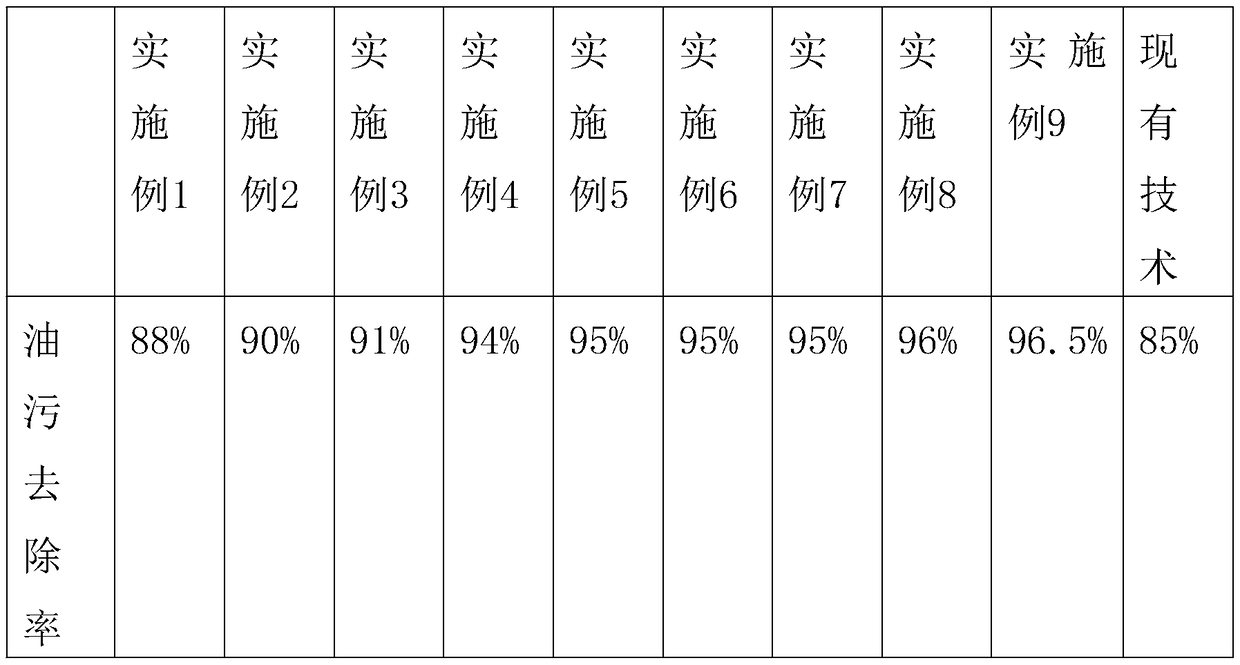

Examples

Embodiment 1

[0023] At 20-30°C, add 48 parts of deionized water into the reactor, then add 2 parts of potassium carbonate, 3 parts of sodium carbonate, 2 parts of potassium silicate, and 4 parts of tetrapotassium pyrophosphate into the reactor in sequence , Stir at 200rpm for 10-15 minutes. After stirring evenly, adjust the temperature of the reactor within the range of 55-60°C, add 9 parts of sodium dodecylbenzenesulfonate, 3 parts of lecithin, and alkyl polyglucoside 4 parts, 4 parts of coconut oil fatty acid diethanolamide, 4 parts of fatty acid sorbitan are added to the reaction kettle in turn, and the reaction kettle is constantly in a stirring state when adding, stirring at 200rpm for 60-90 minutes, after stirring evenly, keep the reaction kettle At a temperature of 55-60°C, add 5 parts of polyglycerin fatty acid ester and 3 parts of polyoxygenated castor oil to the reactor in sequence, and stir at 200 rpm for 30 minutes. After stirring evenly, cool the temperature of the reactor to 3...

Embodiment 2

[0025] At 20-30°C, add 48 parts of deionized water into the reactor, then add 2 parts of potassium carbonate, 3 parts of sodium carbonate, 2 parts of potassium silicate, and 4 parts of tetrapotassium pyrophosphate into the reactor in sequence , Stir at 200rpm for 10-15 minutes. After stirring evenly, adjust the temperature of the reactor within the range of 55-60°C. Add 10 parts of sodium dodecylbenzenesulfonate, 3 parts of lecithin, and alkyl polyglucoside 4 parts, 4 parts of coconut oil fatty acid diethanolamide, 4 parts of fatty acid sorbitan are added to the reaction kettle in turn, and the reaction kettle is constantly in a stirring state when adding, stirring at 200rpm for 60-90 minutes, after stirring evenly, keep the reaction kettle At a temperature of 55-60°C, add 5 parts of polyglycerin fatty acid ester and 3 parts of polyoxygenated castor oil to the reactor in sequence, and stir at 200 rpm for 30 minutes. After stirring evenly, cool the temperature of the reactor to ...

Embodiment 3

[0027] At 20-30°C, add 48 parts of deionized water into the reactor, then add 2 parts of potassium carbonate, 3 parts of sodium carbonate, 2 parts of potassium silicate, and 4 parts of tetrapotassium pyrophosphate into the reactor in sequence , Stir at 200rpm for 10-15 minutes. After stirring evenly, adjust the temperature of the reactor within the range of 55-60°C. Add 11 parts of sodium dodecylbenzenesulfonate, 3 parts of lecithin, and alkyl polyglucoside 4 parts, 4 parts of coconut oil fatty acid diethanolamide, 4 parts of fatty acid sorbitan are added to the reaction kettle in turn, and the reaction kettle is constantly in a stirring state when adding, stirring at 200rpm for 60-90 minutes, after stirring evenly, keep the reaction kettle At a temperature of 55-60°C, add 5 parts of polyglycerin fatty acid ester and 3 parts of polyoxygenated castor oil to the reactor in sequence, and stir at 200 rpm for 30 minutes. After stirring evenly, cool the temperature of the reactor to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com