Bactericidal composition and applications thereof

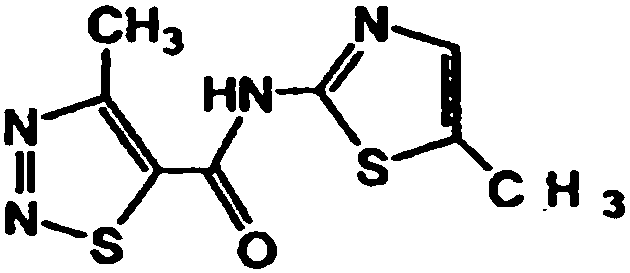

A composition and biostimulant technology, applied in the application, fungicide, biocide and other directions, can solve the problems of no good therapeutic effect on plants, unstable performance of single dose of methiazine, fluctuation of control effect, etc. Widen the spectrum of disease control, good induction of resistance, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: 30.03% thiamin · humic acid microemulsion

[0065] Components: Methiamin 30%, humic acid 0.03%, non-ionic active agent Nongru 600#3%, anionic surfactant Nongru500#3%, xylene 1%, methanol 5%, water supplement 100%.

[0066] Preparation method: Mix the emulsifier and the original pesticide to form a solution, then add other solvents, drop into water under high-speed stirring, and form a transparent o / w microemulsion.

Embodiment 2

[0070] Embodiment 2: 25.05% methiamine · humic acid water dispersible granules

[0071] Components: Methiamin 25%, Humic Acid 0.05%, Sodium Alkyl Naphthalene Sulfonate 5%, Sodium Lignosulfonate 7%, Sodium Lauryl Sulfonate 2%, Ammonium Sulfate 5%, Kaolin Sulfonate Remain.

[0072] Preparation method: Mix the components uniformly to obtain a mixture, the mixture is mechanically pulverized and then jet-pulverized to obtain a secondary mixture, add water with 10%-15% of the mass of the secondary mixture to the secondary mixture, mix uniformly, and then pass through Extrude and granulate to form columnar or spherical granules, and finally dry to obtain 25.05% thiamin·humic acid water-dispersible granules.

Embodiment 3

[0076] Embodiment 3: 25.25% Methiamin Humic Acid Suspension Concentrate

[0077] Components: Methiamin 25%, Humic Acid 0.25%, Sodium Methyl Naphthalene Sulfonate Formaldehyde Condensate 1%, Sodium Lignosulfonate 3%, Xanthan Gum 2%, Bentonite 1%, Glycerol 5 %, make up to 100% with water.

[0078] Preparation method: Mix the components, mix them uniformly by high-speed shearing, and then sand them with a sand mill for 2-3 hours, so that the average particle size reaches 1-5 microns, and you can prepare 25.25% thiamin. Glycolic acid suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com