Sulfur-tolerant pre-shift catalyst and preparation method thereof

A catalyst and pre-conversion technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of low activity, achieve low cost, reduce preparation cost, stable structure and activity good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

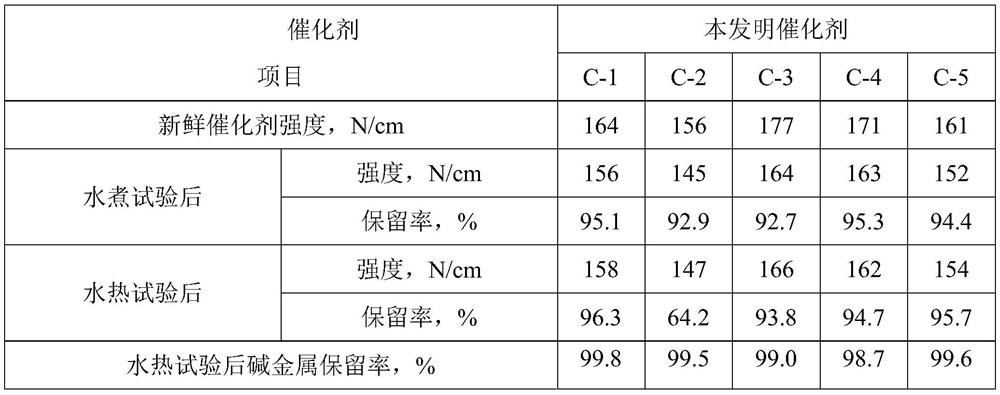

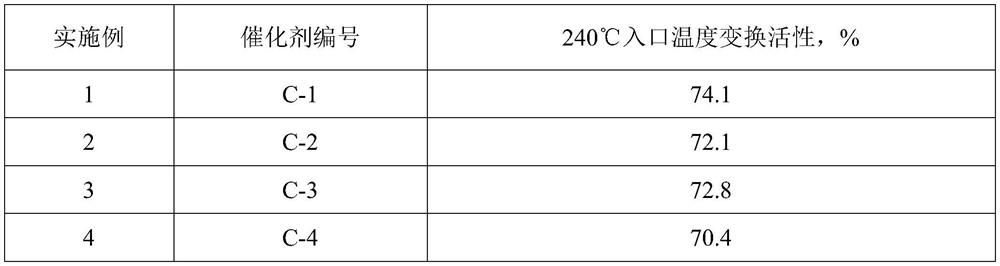

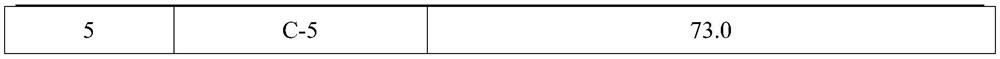

Examples

Embodiment 1

[0045] Weigh 7.8g of cobalt nitrate and 9.8g of ammonium molybdate, add 40ml of ammonia water and 1ml of ethylenediamine, and heat to 60°C to obtain clear solution A. Add 3g of oxalic acid and 1ml of dilute nitric acid to 15ml of deionized water respectively to obtain solution B.

[0046] First roast the waste FCC agent at 600°C for 6 hours, crush it, pass through a 180-mesh sieve, then take 72g of the waste FCC agent, mix it with 18g kapinestone and 4g Tianqing powder, add solution A, and knead evenly; then add solution B, knead evenly , after molding, air-dried, and then calcined at 480°C for 3 hours, the finished catalyst C-1 was obtained.

Embodiment 2

[0048] Weigh 11.7g of cobalt nitrate and 8.6g of ammonium molybdate, add 50ml of ammonia water and 2ml of ethylenediamine, and heat to 70°C to obtain clear solution A. Add 3g of citric acid and 2ml of acetic acid to 20ml of deionized water respectively to obtain solution B.

[0049] The waste FCC agent was roasted at 500°C for 10 hours, pulverized, and passed through a 200-mesh sieve. Then, 63g of the waste FCC agent was mixed with 27g of kanestone and 5g of starch. Add solution A and knead evenly; then add solution B, knead evenly, Shaping, drying at 60°C for 3 hours, and then calcination at 550°C for 3 hours to obtain the finished catalyst C-2.

Embodiment 3

[0051] Weigh 3.9g of cobalt nitrate and 4.9g of ammonium molybdate, add 30ml of ammonia water and 1ml of ethylenediamine, and heat to 50°C to obtain clear solution A. Add 3g of oxalic acid and 2g of citric acid to 25ml of deionized water respectively to obtain solution B.

[0052] The waste FCC agent is roasted at 700°C for 2 hours, crushed and passed through a 210-mesh sieve, and then 59g of the waste FCC agent is mixed with 36g of kanestone and 2g of Tianqing powder, and then added to solution A and kneaded evenly; then added to solution B and kneaded evenly , after molding, drying at 60°C for 3 hours, and then calcining at 400°C for 3 hours, the finished catalyst C-3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com