Coating film removing agent and polymerization method for improving porosity of polyvinyl chloride resin

A polyvinyl chloride resin and a polymerization method technology, applied in the field of polymer polymerization, can solve the problems of reducing the surface film, affecting the stability of the polymerization system, and limited improvement of the resin particle structure, so as to increase the pore structure and increase the surface pore structure. , the effect of reducing the apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

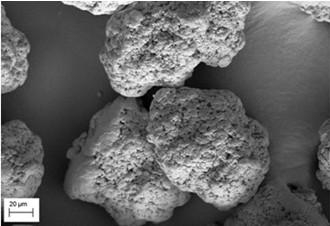

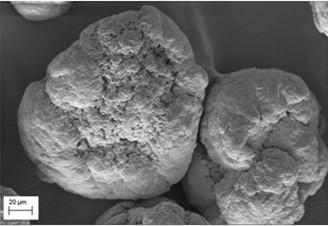

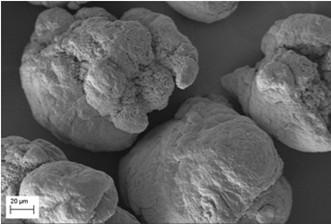

Image

Examples

Embodiment 1

[0035] The film remover is a mixture of glyceryl monostearate and toluene, and the mass ratio of glyceryl monostearate to toluene is 1:5.5.

[0036]Polymerization method: Add 4480g desalted water, 13.44g polyvinyl alcohol 424H 5.0% aqueous solution, 33.6g hydroxypropyl methylcellulose FON50 3% aqueous solution, 4.0g to a 10L stainless steel pressure reactor equipped with double-layer flat paddles Polyvinyl alcohol S202 concentration 35% methanol solution, 31.7g film remover, 0.56g cumyl peroxyneodecanoate, 1.68g bis(2-ethylhexyl peroxydicarbonate); closed reaction kettle, vacuum When the pressure is lower than -0.090MPa, add 2520g of vinyl chloride monomer and 280g of diallyl maleate, start stirring, stir and mix at room temperature for 10 minutes, then raise the temperature of the kettle to 58.0°C for polymerization; when the pressure in the kettle When the drop value reaches 0.10MPa, add 14.0g of 2.0% diethylhydroxylamine aqueous solution to the kettle to terminate the react...

Embodiment 2

[0038] The film remover is a mixture of mixed glyceryl stearate and toluene, and the mass ratio of mixed glyceryl stearate to toluene is 1:3.

[0039] Polymerization method: Add 4480g desalted water, 13.44g polyvinyl alcohol 424H 5.0% aqueous solution, 33.6g hydroxypropyl methylcellulose FON50 3% aqueous solution, 4.0g to a 10L stainless steel pressure reactor equipped with double-layer flat paddles Polyvinyl alcohol S202 concentration 35% methanol solution, 31.7g film remover, 0.56g cumyl peroxyneodecanoate, 1.68g bis(2-ethylhexyl peroxydicarbonate). Close the reaction kettle, evacuate until the pressure is lower than -0.090MPa, add 2520g vinyl chloride monomer and 280g diallyl maleate, start stirring, stir and mix at room temperature for 10 minutes, then raise the temperature of the kettle to 58.0°C for polymerization reaction. When the pressure drop in the kettle reached 0.10 MPa, 14.0 g of 2.0% diethylhydroxylamine aqueous solution was added to the kettle to terminate the...

Embodiment 3

[0041] The film remover is a mixture of monoglyceride laurate and toluene, and the mass ratio of monoglyceride laurate to toluene is 1:5.5.

[0042] Polymerization method: Add 4480g desalted water, 13.44g polyvinyl alcohol 424H 5.0% aqueous solution, 33.6g hydroxypropyl methylcellulose FON50 3% aqueous solution, 4.0g to a 10L stainless steel pressure reactor equipped with double-layer flat paddles Polyvinyl alcohol S202 concentration 35% methanol solution, 31.7g film remover, 0.56g cumyl peroxyneodecanoate, 1.68g bis(2-ethylhexyl peroxydicarbonate). Close the reaction kettle, evacuate until the pressure is lower than -0.090MPa, add 2520g vinyl chloride monomer and 280g diallyl maleate, start stirring, stir and mix at room temperature for 10 minutes, then raise the temperature of the kettle to 58.0°C for polymerization reaction. When the pressure drop in the kettle reached 0.10 MPa, 14.0 g of 2.0% diethylhydroxylamine aqueous solution was added to the kettle to terminate the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com